Ampere force driving micro spraying device

A driving type and nozzle technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of high physical and chemical properties of the liquid, complex structure, etc., and achieve the effect of simple structure and good electrical control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

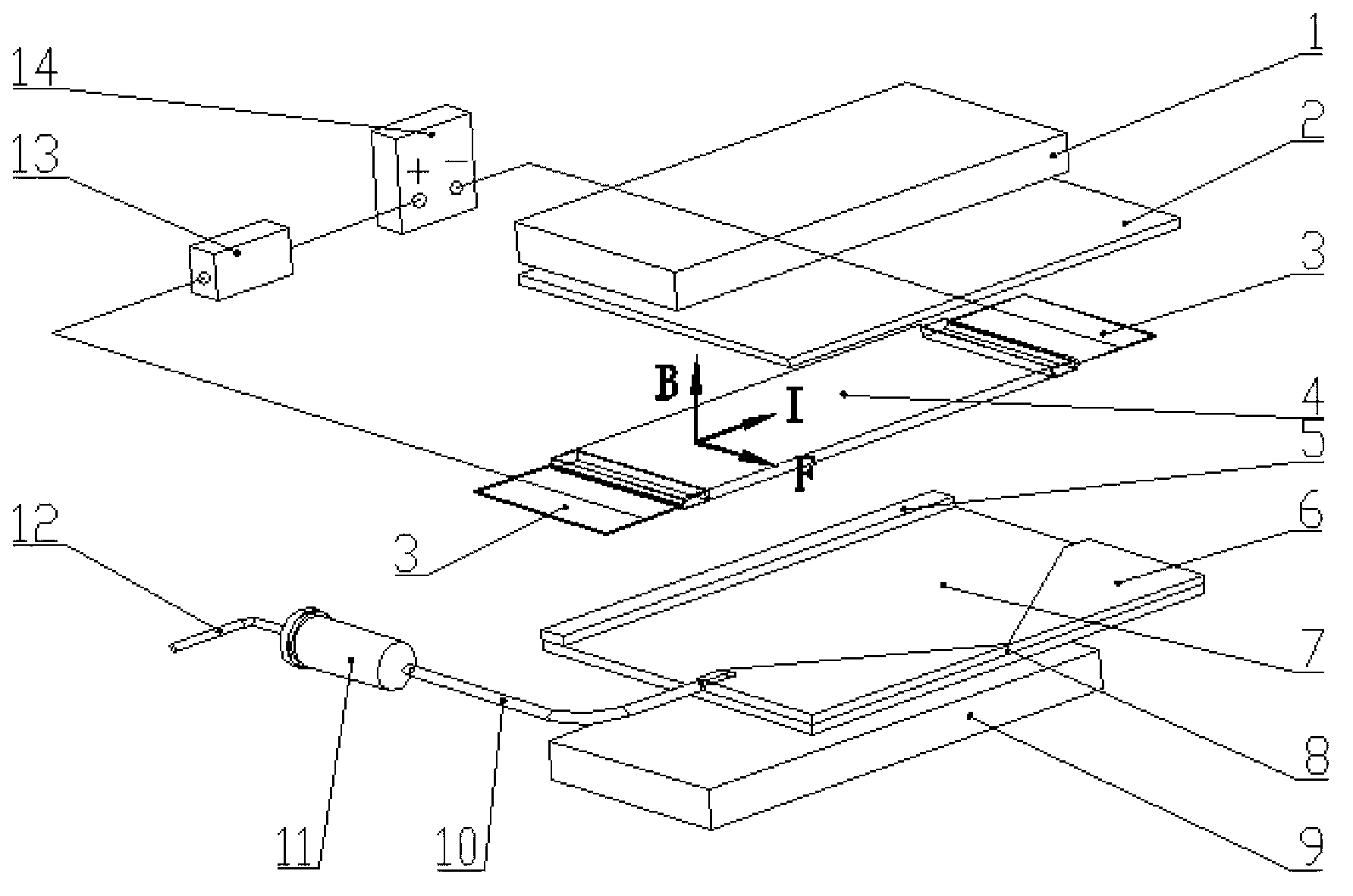

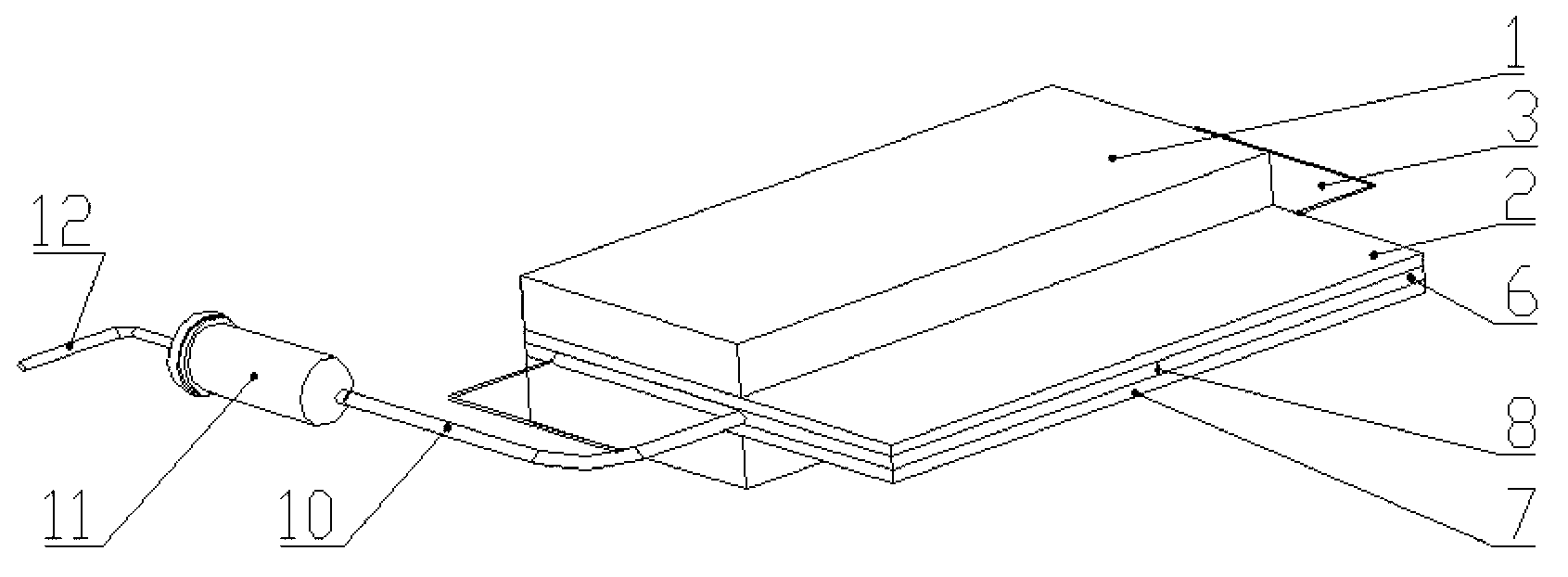

[0015] see figure 1 and 2 , the embodiment of the present invention is provided with upper magnet 1, upper cover plate 2, lower cover plate 7, intermediate baffle plate 5, guide plate 6, lower magnet 9, electrode 3, flexible conductive actuator 4, nozzle 8, infusion fluid Tube 10, liquid storage tank 11, air tube 12, pulse current controller 13 and power supply 14.

[0016] The upper magnet 1 is fixed on the surface of the upper cover plate 2 . The intermediate baffle plate 5 and the guide plate 6 are fixed on the surface of the lower cover plate 7 . The upper cover 2 is connected with the lower cover 7 . The lower magnet 9 is fixed on the bottom surface of the lower cover plate 7 . The electrodes 3 are connected to both ends of the flexible conductive actuator 4 . The flexible conductive actuator 4 is located between the bottom surface of the upper cover plate 2 and the surface of the lower cover plate 7 . The upper cover plate 2 , the lower cover plate 7 , the guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com