Pre-spray water guiding mechanism for laser wet cutting

A water guiding mechanism and wet cutting technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult removal of debris, thermal damage of parts, etc., to achieve stable water supply, low equipment cost, and overcome insufficient water supply. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

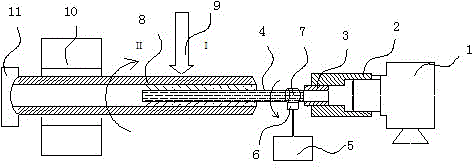

[0024] A pre-spray water guide mechanism for laser wet cutting processing, such as figure 1 As shown, it includes motor 1, coupling 2, bushing 3, water guide pipe 4, automatic water supply system 5 and water inlet 6, motor 1 is connected with water guide pipe 4 through coupling 2, bushing 3, and one end of bushing 3 Located in the coupling 2, the other end is in sealing connection with the water guide pipe 4, and the end of the water guide pipe 4 near the bush 3 has a water inlet 6, and the water inlet 6 is connected with the automatic water supply system 5 sealed bearing 7, and the outer diameter of the water guide pipe 4 is smaller than that to be The inner diameter of the pipe material 8 is processed, and the water guide pipe 4 is inserted into the inside of the pipe material to be processed away from the end of the bushing 3 .

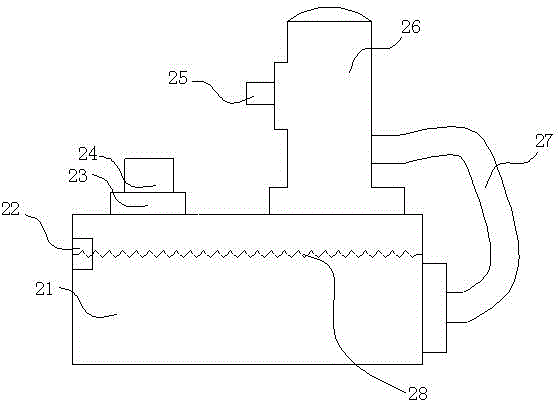

[0025] The automatic water supply device described, such as figure 2 As shown, it includes a water tank 21, a liquid level sensor 22, a second w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com