Preparation method and application of a composite heating sheet for thermal battery

A composite heating and thermal battery technology, applied in the use/maintenance of primary batteries, primary batteries, battery electrodes, etc., can solve problems such as the working time of the thermal battery does not meet the use requirements, the working time of the thermal battery is shortened, and the temperature of the thermal battery increases. , to achieve the effect of prolonging the heat release time, preventing over-burning and avoiding thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

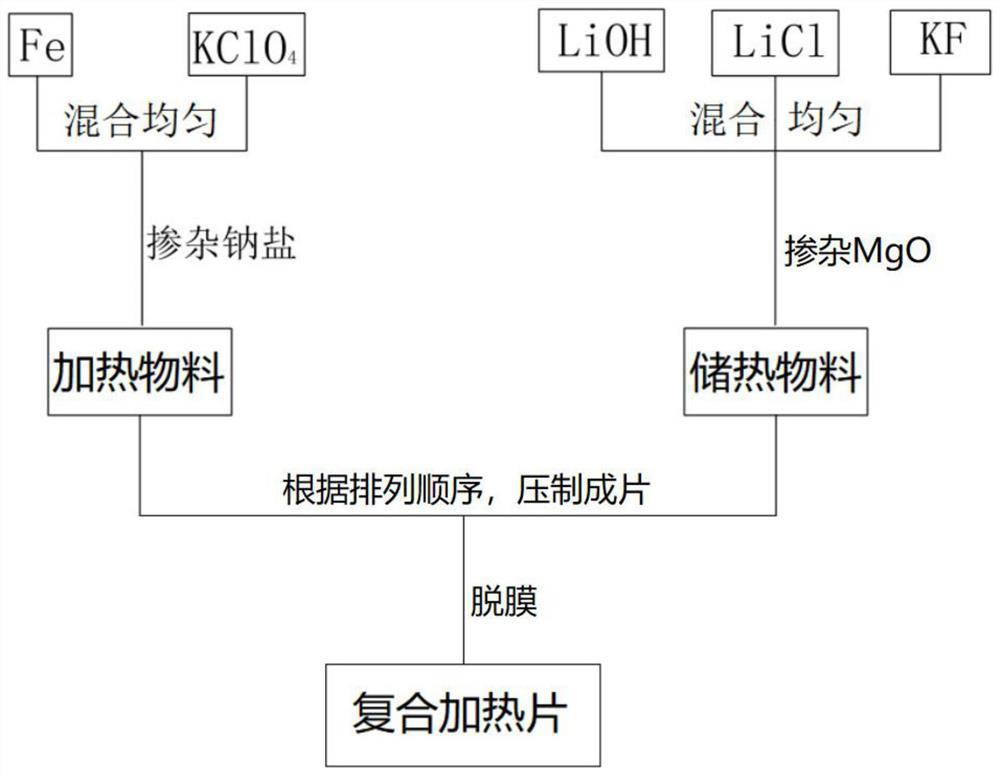

[0030] A method for preparing a composite heating sheet for a thermal battery, the composite heating sheet is made of a heating material and a heat storage material, the outer surface of the composite heating sheet is a heating material, and the inside thereof is a heat storage material or a heat storage material and The heating materials are arranged in phases, and the preparation method thereof comprises the following steps:

[0031] (1) Preparation of heating materials: take Fe powder and KClO in proportion 4 powder, stir well and add sodium salt, mix well and sieve to obtain heating material; the Fe powder and KClO 4 The mass ratio of powder=80:10; The sodium salt is NaCl or Na 2 SO 4 , and the quality of sodium salt is 1% of the heating material;

[0032] (2) Preparation of heat storage material: Weigh LiOH, LiCl and KF powder according to the proportion, add MgO powder after stirring evenly, and sieve after mixing uniformly to obtain heat storage material; the mass ra...

Embodiment 2

[0036] A method for preparing a composite heating sheet for a thermal battery, the composite heating sheet is made of a heating material and a heat storage material, the outer surface of the composite heating sheet is a heating material, and the inside thereof is a heat storage material or a heat storage material and The heating materials are arranged in phases, and the preparation method thereof comprises the following steps:

[0037] (1) Preparation of heating materials: take Fe powder and KClO in proportion 4 powder, stir well and add sodium salt, mix well and sieve to obtain heating material; the Fe powder and KClO 4 The mass ratio of powder=90:20; The sodium salt is NaCl or Na 2 SO 4 , and the quality of sodium salt is 10% of the heating material;

[0038] (2) Prepare heat storage material: take LiOH, LiCl and KF powder according to the proportion, add MgO powder after stirring evenly, sieve after mixing uniformly, make heat storage material; The mass ratio of describe...

Embodiment 3

[0042] A method for preparing a composite heating sheet for a thermal battery, the composite heating sheet is made of a heating material and a heat storage material, the outer surface of the composite heating sheet is a heating material, and the inside thereof is a heat storage material or a heat storage material and The heating materials are arranged in phases, and the preparation method thereof comprises the following steps:

[0043] (1) Preparation of heating materials: take Fe powder and KClO in proportion4 powder, stir well and add sodium salt, mix well and sieve to obtain heating material; the Fe powder and KClO 4 The mass ratio of powder=82:13; The sodium salt is NaCl or Na 2 SO 4 , and the quality of sodium salt is 3% of the heating material;

[0044] (2) Prepare heat storage material: take LiOH, LiCl and KF powder according to the proportion, add MgO powder after stirring evenly, sieve after mixing uniformly, make heat storage material; the mass ratio of described L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com