An electric elastic plate active sound insulation actuator

An elastic plate and electric technology, which is applied in the direction of engine components, machines/engines, noise reduction devices, etc., can solve the problem of large axial length of electric actuators, limited service life of leaf springs, and greater influence of elastic plate structures, etc. problems, to achieve the effect of increasing the use method and scope, high utilization rate of magnetic energy, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

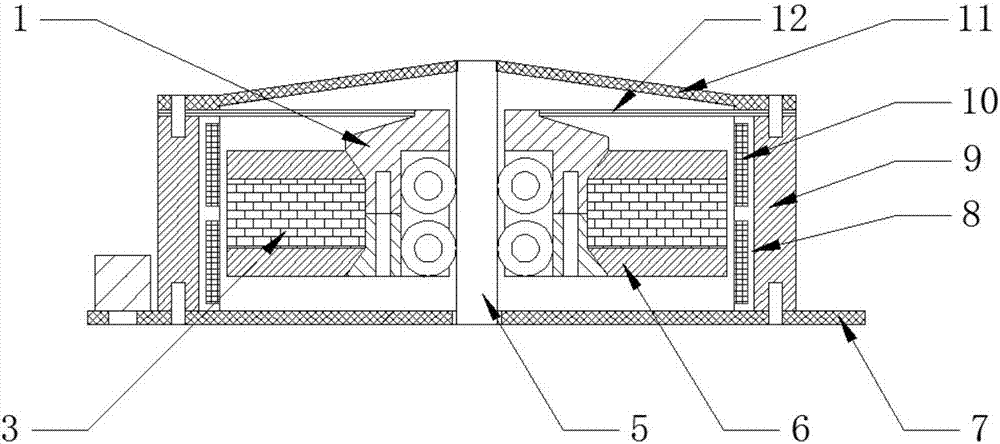

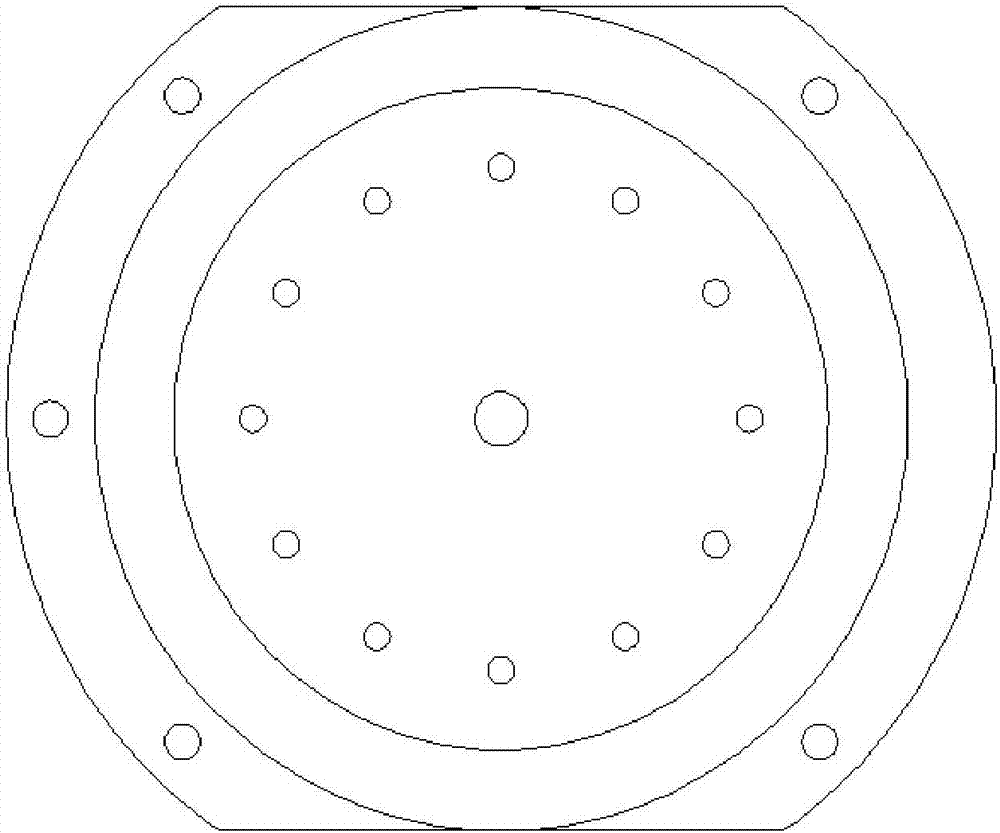

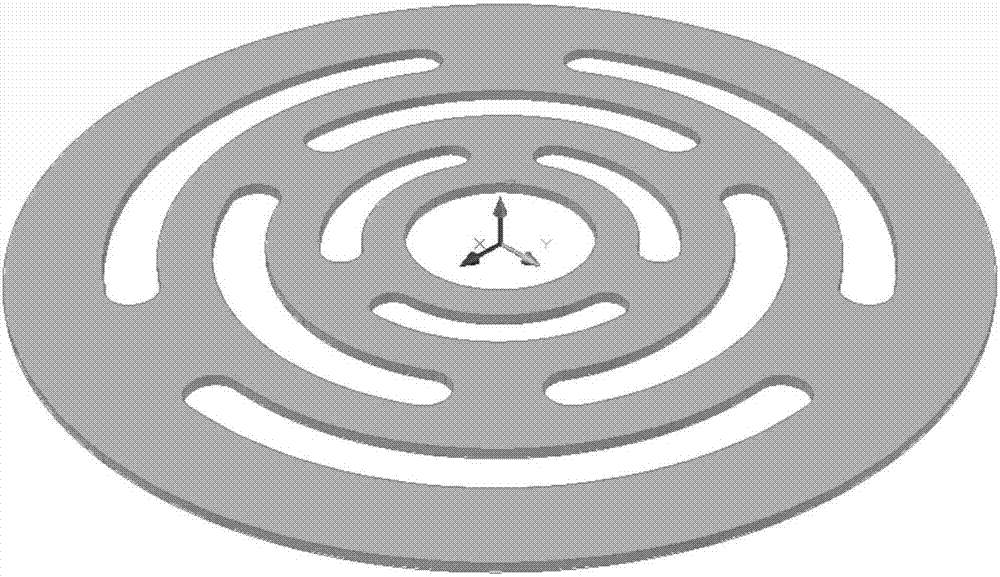

[0021] to combine Figure 1~3 , the present invention includes an annular permanent magnet, two upper and lower annular magnetic steels and an outer magnetic tube. The permanent magnet, magnetic steel and pulley assembly constitute the mass part of the mover, which is in contact with the central axis of the actuator through the guide wheel, and connected with the outer magnetic cylinder through the metal leaf spring. This embodiment also includes a coil and a coil holder, the coil is wound and embedded in the coil holder, and the outer wall of the annular coil holder cooperates with the inner wall of the outer magnetic tube. When the coil is energized, the mass part of the mover reciprocates under the action of the electromagnetic excitation force of the energized coil, thereby generating force to effectively implement the control of the controlled object and red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com