Laser wet cutting processing method

A technology of cutting processing and laser cutting machine, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., which can solve the problems of difficult removal of debris and thermal damage of parts, so as to improve processing quality, prevent excessive burning, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

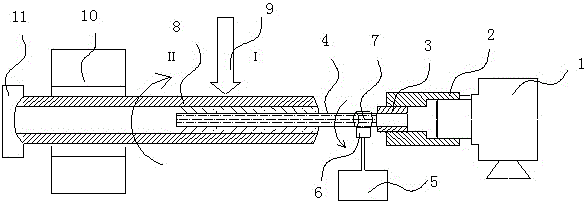

[0042] This example provides a laser wet cutting processing method, which includes the following steps: fixing the pipe to be cut on the rotating shaft of the laser cutting machine with a pre-spray structure and a coaxial nozzle; The water guide pipe of the system is inserted from one end of the thin-walled pipe to be cut; start the rotating shaft of the laser cutting machine to rotate the pipe to be cut; start the water guide system of the laser cutting machine to rotate the water guide pipe; start the water circulation module of the laser cutting machine ;Start the cutting head of the laser cutting machine to cut the pipe;

[0043] Wherein, the laser cutting machine containing pre-spray structure and coaxial nozzle, such as figure 1 As shown, it includes a coaxial water jet device 9, a fixture 10, a sealing plug 11 and a pre-spray water-guiding mechanism, the pre-spray water-guiding mechanism contains an automatic water supply system; the pre-spray water-guiding mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com