Wet Laser Cutting Machine

A laser cutting machine and wet-type technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of thermal damage to parts and difficult removal of debris, and achieve low equipment cost, stable water supply, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

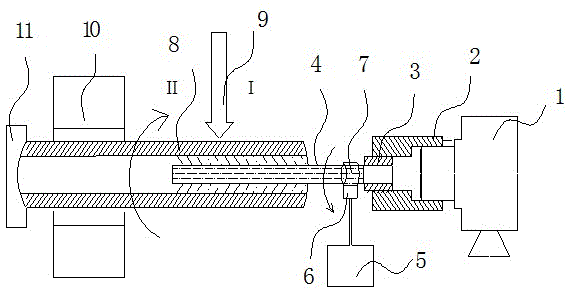

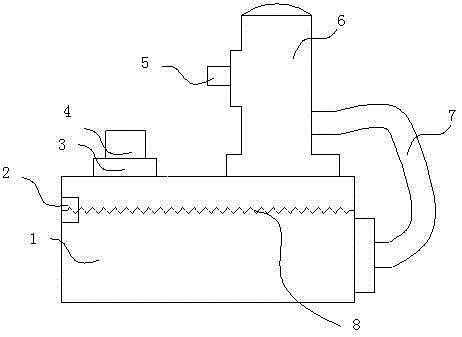

[0024] A wet laser cutting machine such as figure 1 As shown, it includes a cutting head 9, a clamp 10, a sealing plug 11 and a pre-spray water-guiding mechanism, and the pre-spray water-guiding mechanism contains an automatic water supply system; , coupling 2, bushing 3, water guide pipe 4, automatic water supply system 5 and water inlet 6, motor 1 is connected through shaft coupling 2, bushing 3 and water guide pipe 4, and one end of bushing 3 is located in coupling 2 , the other end is in sealing connection with the water guide pipe 4, the water guide pipe 4 has a water inlet 6 at one end close to the bushing 3, the water inlet 6 is connected with the automatic water supply system 5 sealed bearing 7, the outer diameter of the water guide pipe 4 is smaller than the inner diameter of the pipe material 8 to be processed, The end of the water guide pipe 4 away from the bushing 3 goes deep into the inside of the pipe to be processed.

[0025] The automatic water supply device d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com