Underground coal mine hydraulic filling double track lifting locomotive and hydraulic control system thereof

A mine car and locomotive technology, applied in cranes, traveling mechanisms, transportation and packaging, etc., can solve problems such as low filling efficiency, endangering the life safety of underground workers, and prone to safety accidents, and achieves simple structure, saving installation space, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

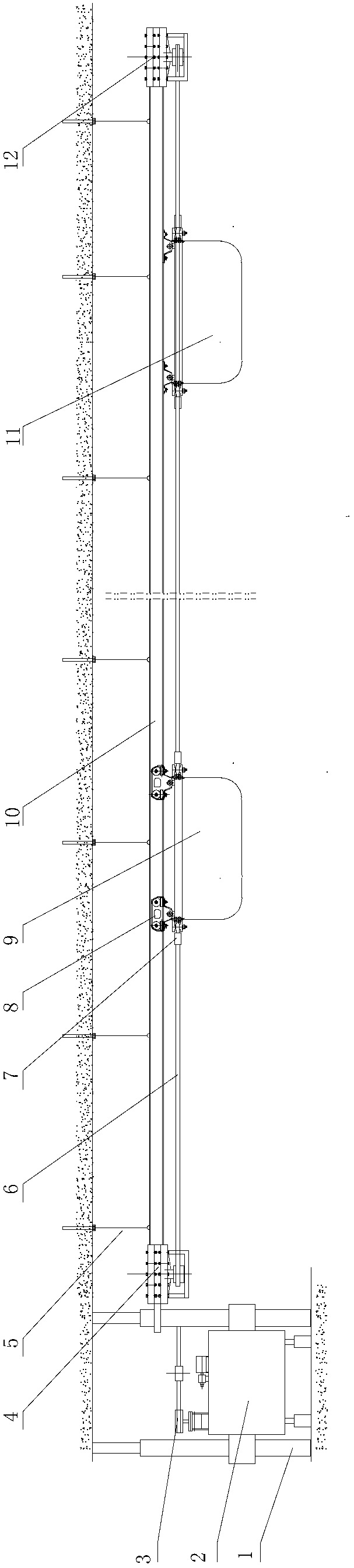

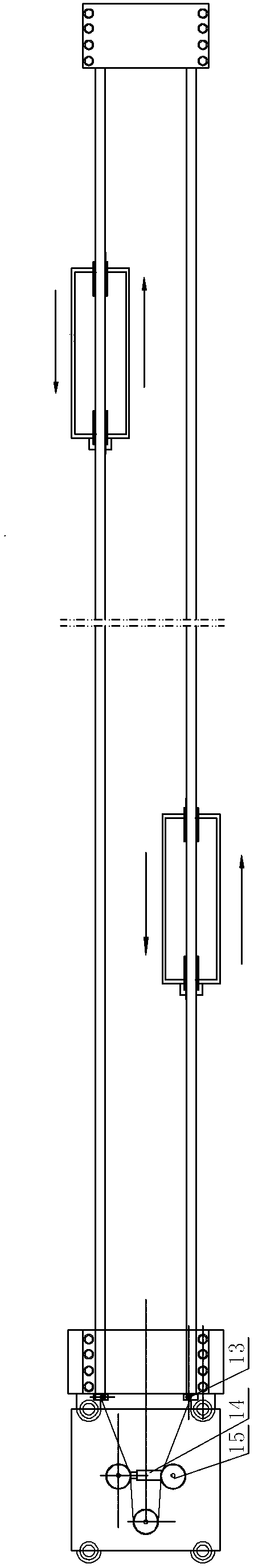

[0019] See attached Figure 1-2 , which describes a preferred embodiment of the coal mine filling hydraulic double-track hoisting locomotive according to the present invention. The hydraulic double-track hoisting locomotive for filling underground coal mines includes two I-steel rails, a mine car suspended on the rails and a PLC controller; The two ends of the cross-shaped steel track are respectively provided with a first fixed end and an end fixed end to prevent the mine car from falling out. A mine car is suspended on each I-shaped steel track, and the mine car is suspended on the I-shaped steel track by a carrying trolley. The carrying trolley includes walking rollers and guide rollers, and the traveling rollers are arranged symmetrically along the track, preferably 8, each There are 4 sides, and the walking rollers are respectively set at the upper and lower ends of the edge of the I-shaped steel track, which are used to carry the mine car and make the mine car move alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com