Simple and rapid preparation process of dihydroartemisinin

A technology of dihydroartemisinin and preparation process, applied in the direction of organic chemistry, etc., can solve the problems of increased environmental damage, large amount of chemical reagents, low atomic economy, etc., achieves great economic and social benefits, and green production procedures Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

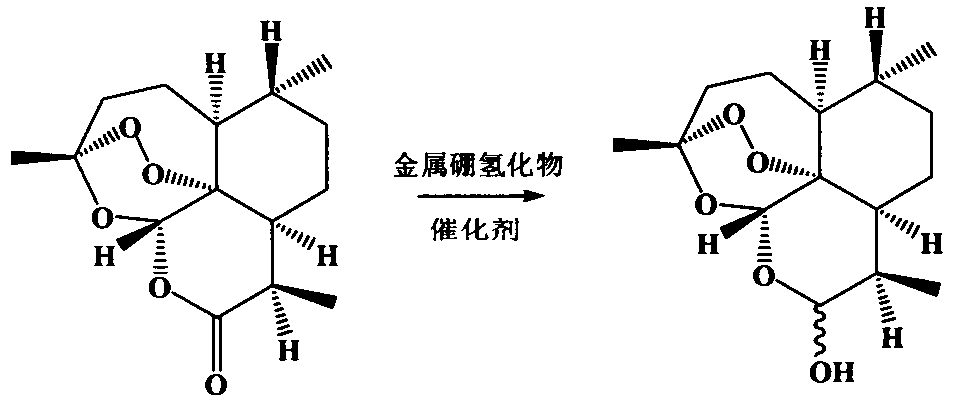

Image

Examples

Embodiment 1

[0017] Embodiment 1 The preparation of dihydroartemisinin 1

[0018] In a 1000L stainless steel reactor, first add 400L of methanol-ethylene glycol (volume ratio 9: 1) mixed solvent, the jacket of the reactor is cooled by icy brine, and at the same time, 50 kg of artemisinin is added while stirring, and the temperature is controlled at 0 Below ℃, start to add 12kg of anhydrous aluminum trichloride as a Lewis acid catalyst, then control the temperature at 0℃ and start to add 5.3kg of sodium borohydride reducing agent in batches, and complete the addition within 20 minutes. Keep the environment of the reactor in a ventilated state, remove a large amount of hydrogen generated by the reactor, keep the temperature of the reaction system below 5°C, keep the reaction for 40 minutes, monitor the completion of the reaction by thin-layer chromatography, that is, the disappearance of artemisinin spots is regarded as the end of the reaction, at this time The pH of the system is about 6. ...

Embodiment 2

[0019] In the 1000L stainless steel reactor, first add 450L of ethanol-isopropanol (volume ratio 9: 1) mixed solvent, the jacket of the reactor is cooled by icy brine, and at the same time add 50kg of artemisinin while stirring, and control the temperature at 0 Below ℃, start to add 15kg of Lewis acid catalyst anhydrous zinc chloride, then control the temperature at 0℃, start to add 6.8kg of potassium borohydride reducing agent in batches, and complete the addition within 20 minutes. Keep the environment of the reactor in a ventilated state, and remove a large amount of hydrogen generated by the reactor. The temperature of the reaction system is always controlled below 5°C. The pH of the system is around 7. Transfer the above reaction solution into a multi-functional stainless steel concentration crystallization pot, depressurize and control the temperature to concentrate and recover the reaction solvent at 45°C. The recovered solvent can be reused directly or after being drie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap