Modular finished product partition system

A modular, finished technology, applied in the field of building decoration engineering, can solve the problems of difficult coordination and unification of corridor façade decoration design, inability of office staff to enjoy shared space, and inability to effectively meet the use functions, etc., to ensure disassembly and assembly, Solve artificial roughness and inaccuracy, and reduce the effect of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

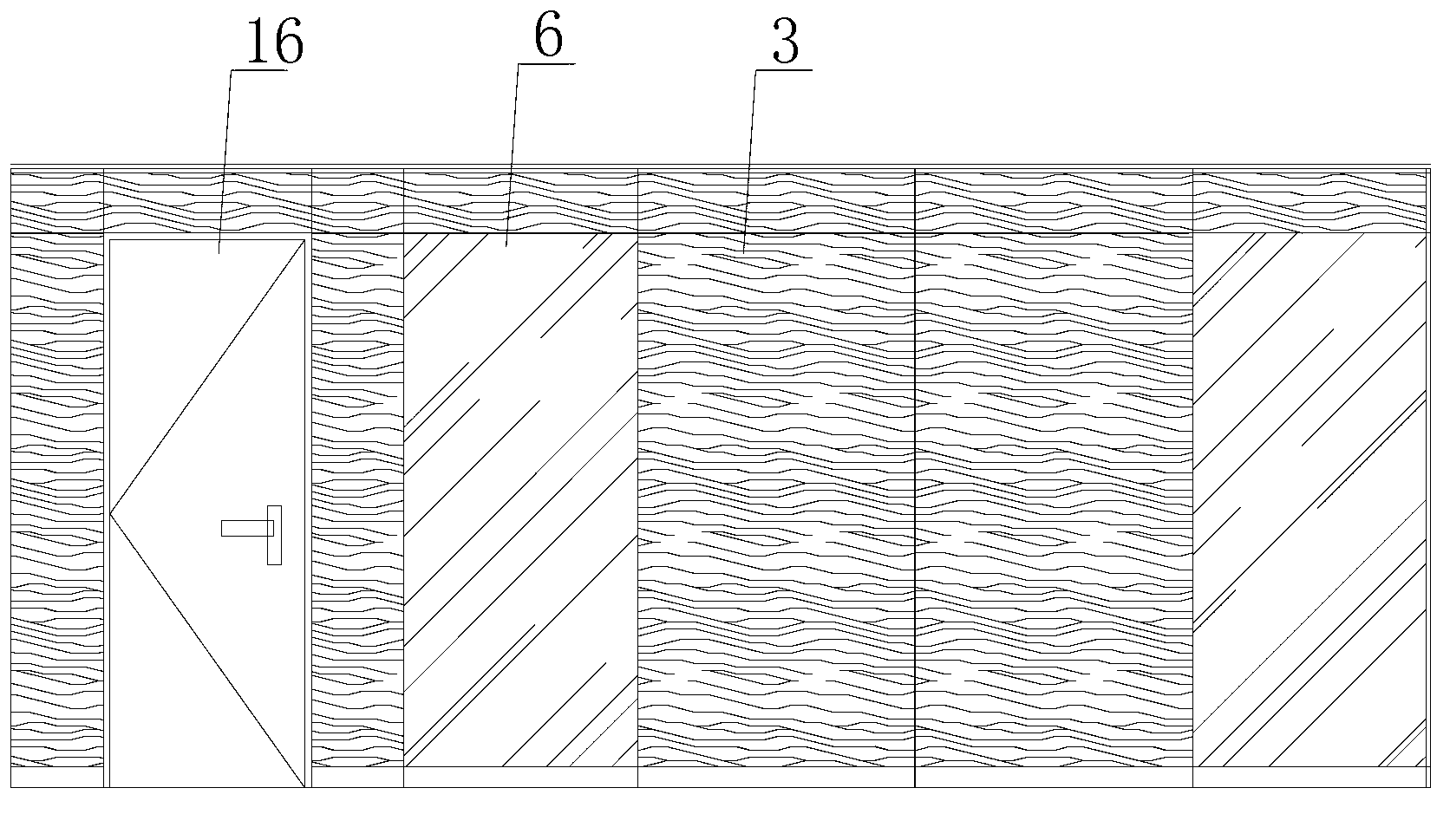

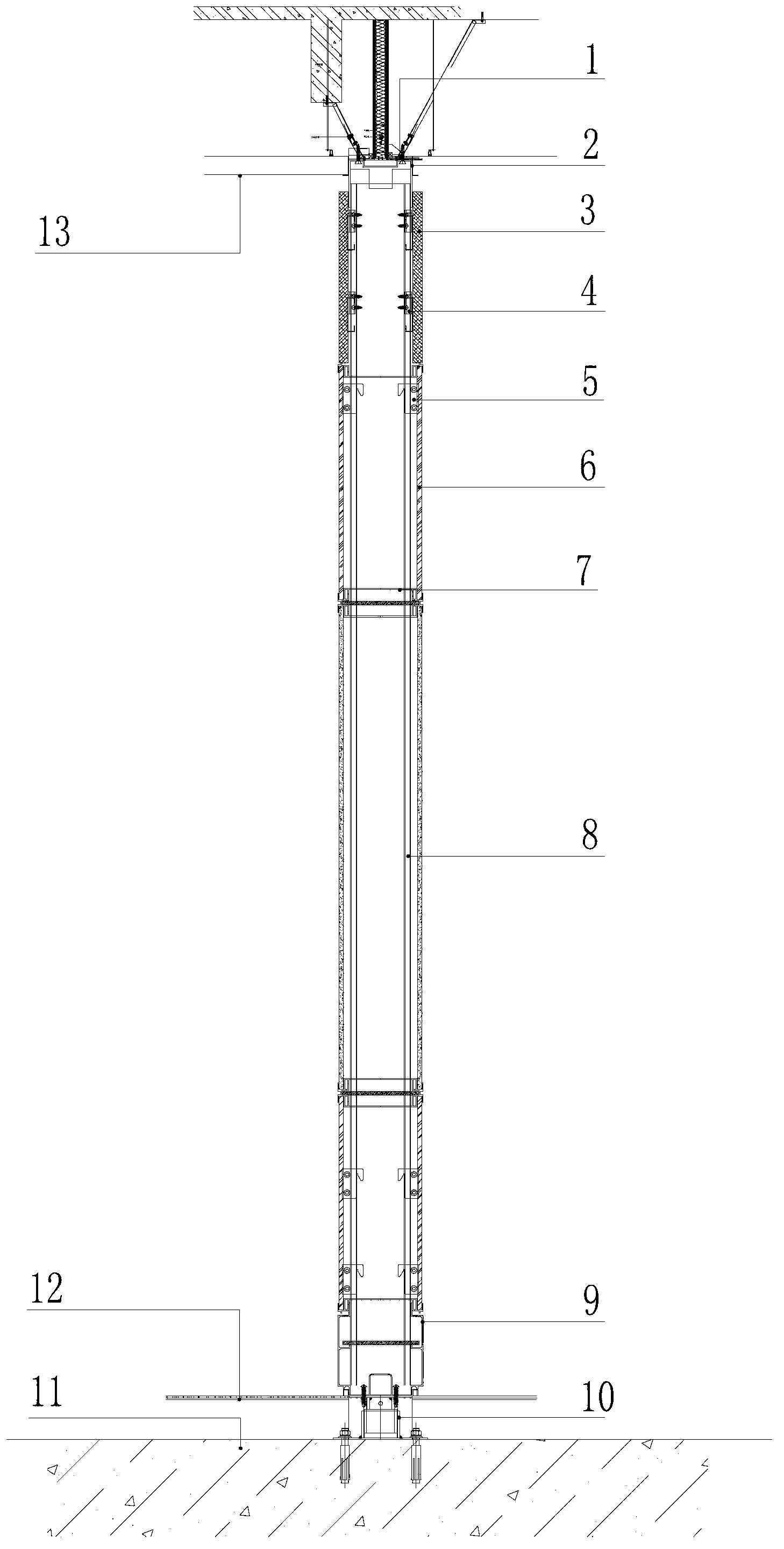

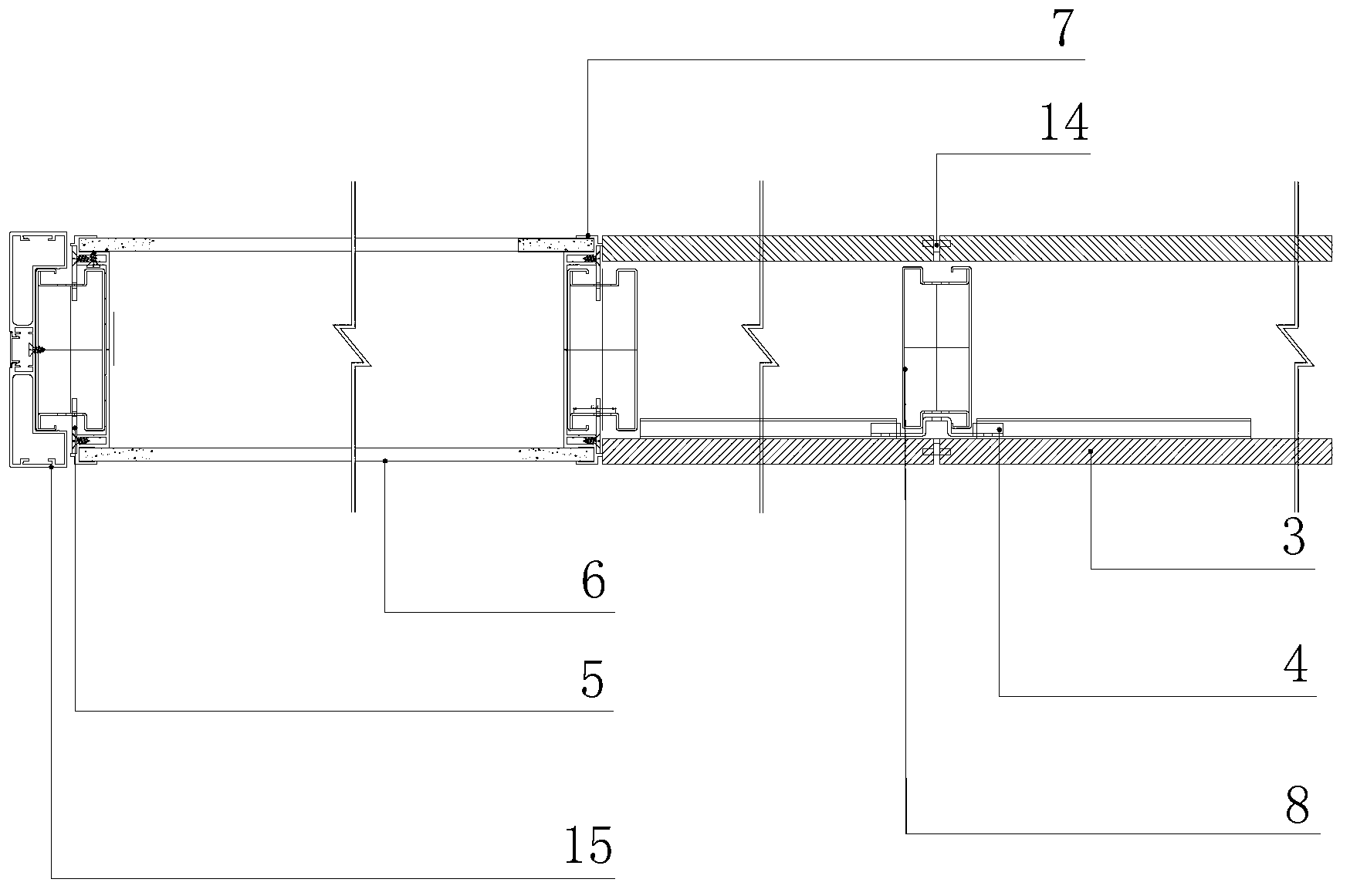

[0020] Such as figure 2 , image 3 As shown, the finished partition wall system includes: 1. The main frame system includes the steel upper channel 2, the steel main keel 8, the lower channel integrated aluminum alloy skirting 9, and the steel adjustment base 10; 2. The panel material includes 12MM Thick finished decorative panel 3, 6MM thick glass panel 6; connectors include L-shaped steel panel fastener 4, L-shaped steel glass frame fastener 5, aluminum alloy glass frame 7.

[0021] Such as Figure 4 Figure 5 As shown, the door system in the finished partition wall system includes: 1. The main frame system includes a steel upper channel 2, a steel main keel 8, a steel adjustment base 10, an aluminum alloy door frame 15, and an airtight anti-collision rubber strip 17; 2. Panel materials include 12MM thick finished decorati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com