Automatically-produced light-emitting diode (LED) lamp tube

A technology for LED lamps and lamps, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve problems such as affecting product quality, low production efficiency, and complicated assembly, and simplify the layout of connecting wires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

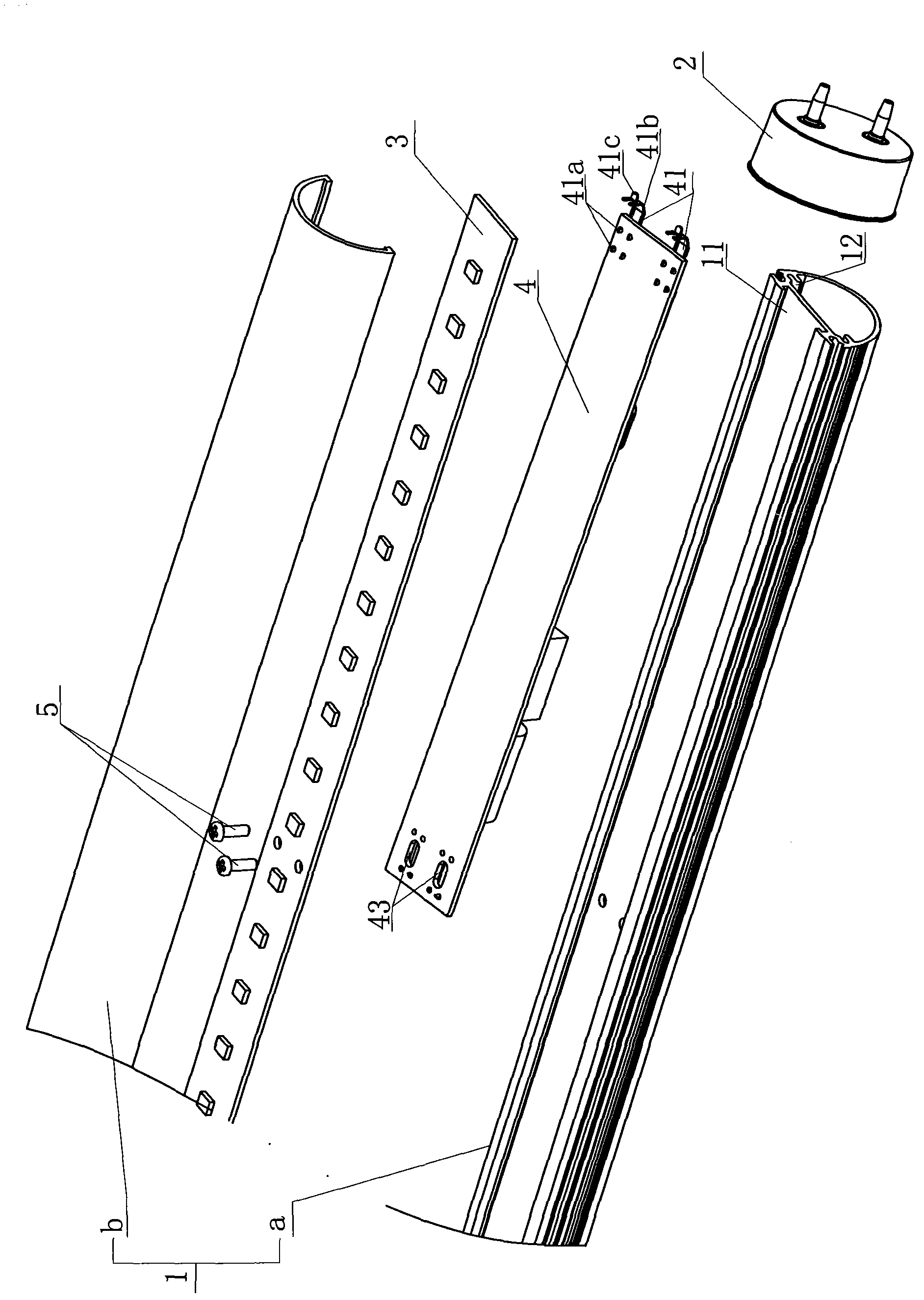

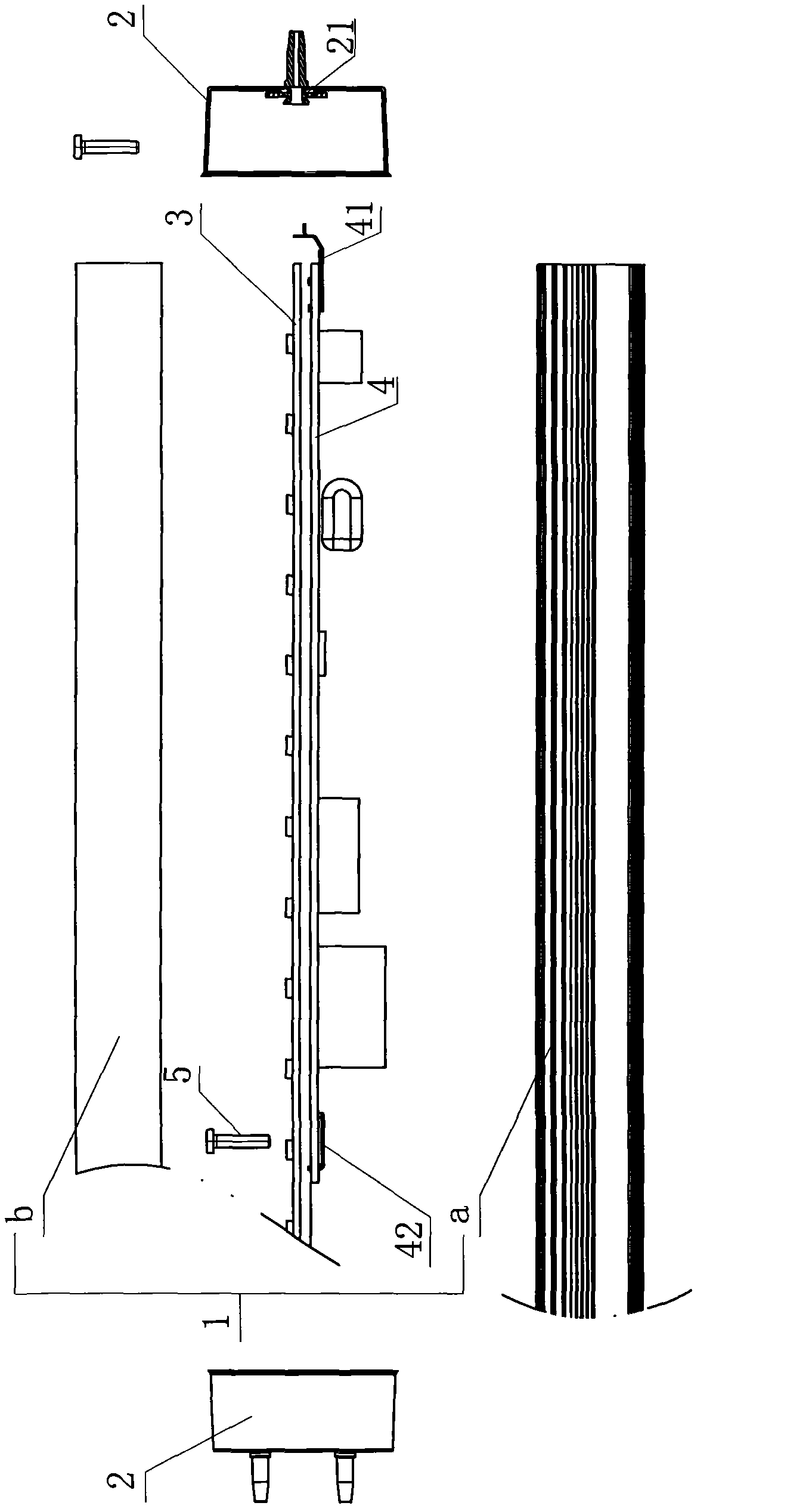

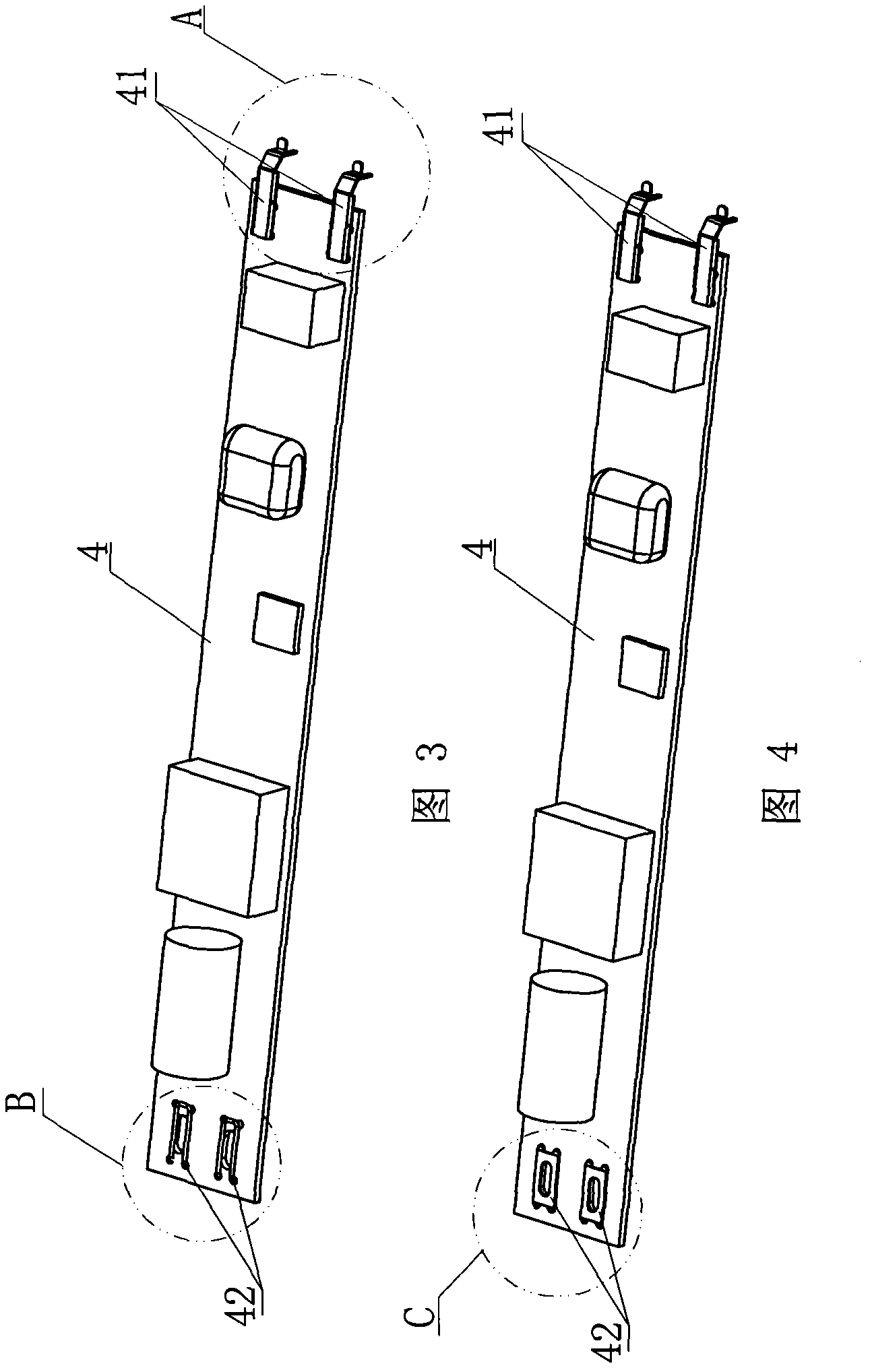

[0042] Such as Figure 1 to Figure 23 Shown: an automatically produced LED lamp tube, including a lamp tube body 1, lamp caps 2 at both ends of the lamp tube body 1, and a light-emitting lamp bead circuit board 3 and a power supply circuit board 4 arranged in the lamp tube body 1, wherein: the lamp The tube body 1 is provided with upper and lower slots 11, 12 arranged in the axial direction, the light-emitting lamp bead circuit board 3 and the power supply circuit board 6 are respectively inserted in it in a stacked arrangement, and one end of the power circuit board 4 is provided with a power supply. Input connector 41, electrical output connector 42 is provided on the board surface, electrode connector 21 is provided at the inner end of the lamp cap 2 to plug and connect with electrical output connector 41, and conductive screw 5 is provided on the board surface of light-emitting lamp bead circuit board 5 for electrical connection Electrical output connector 42 .

[0043] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com