Automatic adjusting device of flame height of lighter

A flame height, automatic adjustment technology, applied in the direction of combustion ignition, lighting and heating equipment, combustion methods, etc., can solve the problems of low measurement accuracy, low degree of automation, high detection environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

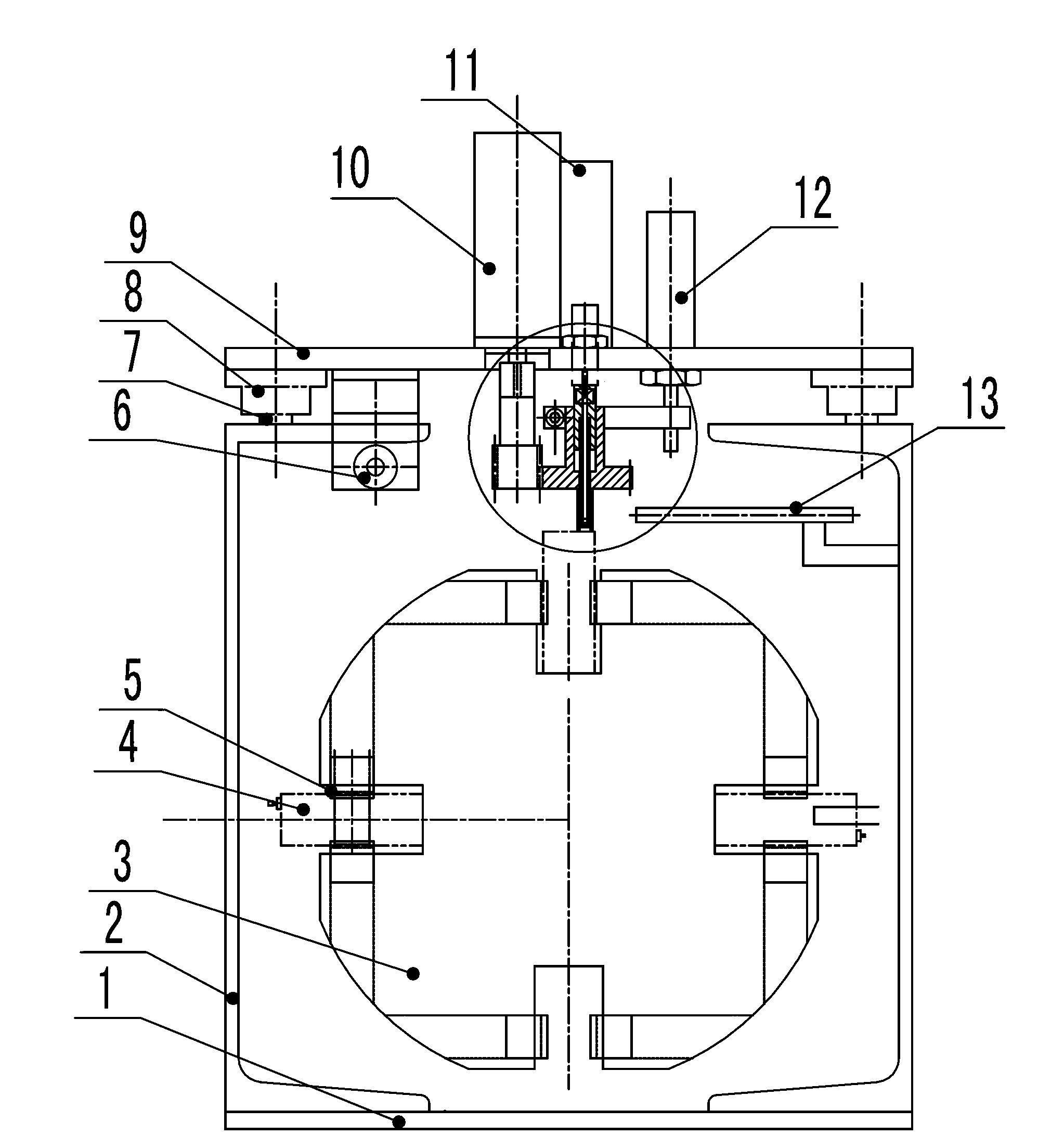

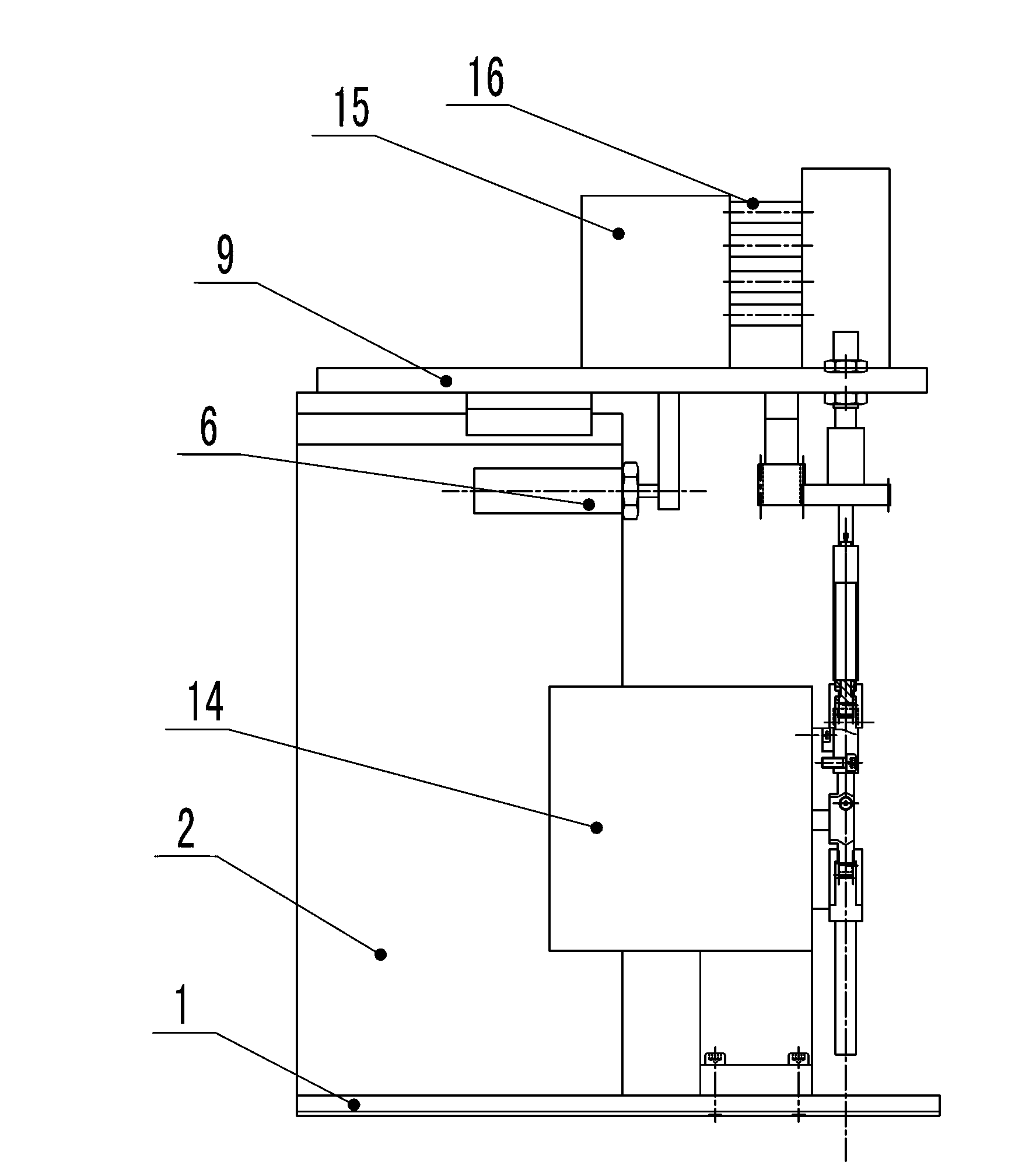

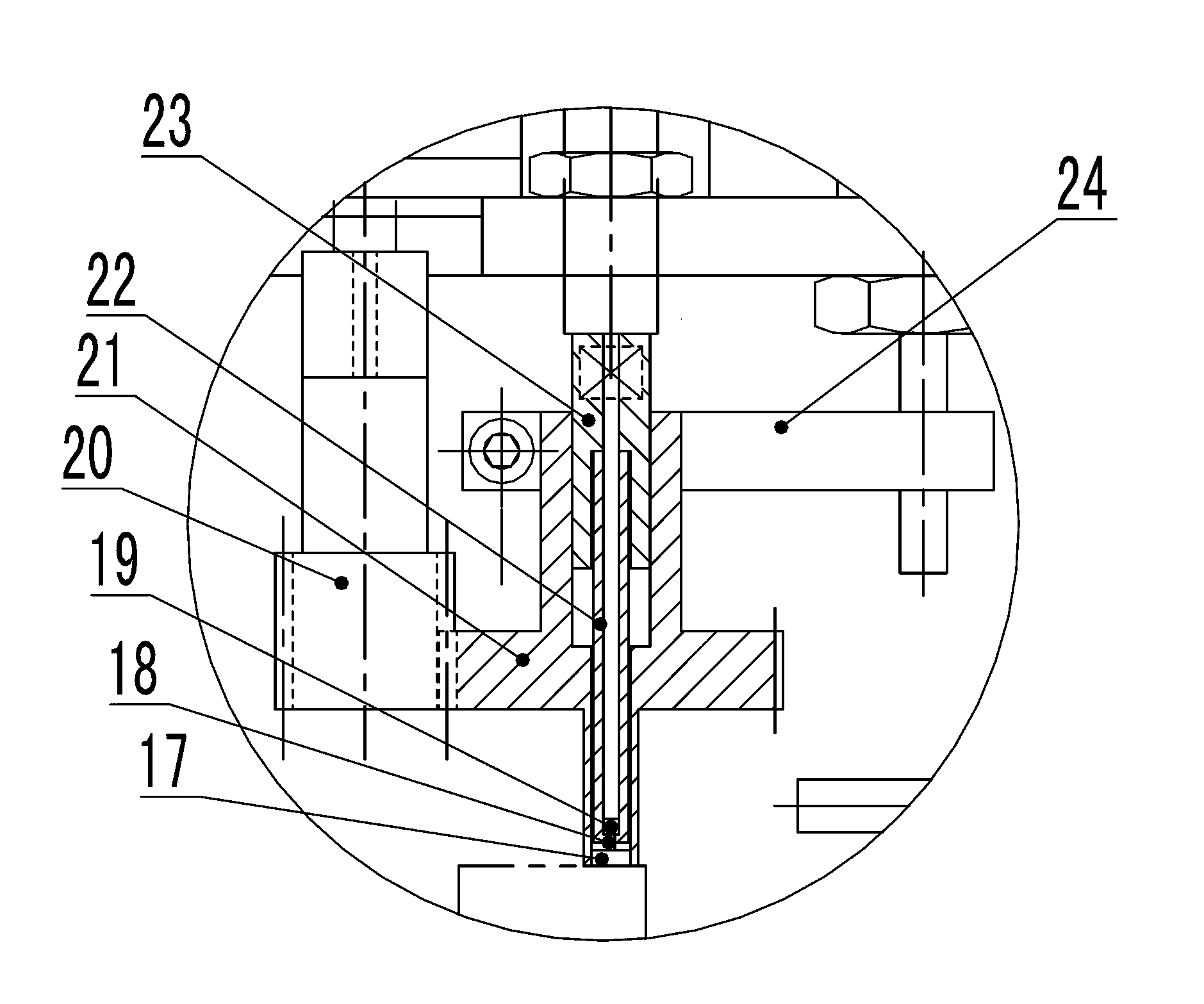

[0018] refer to figure 1 , figure 2 , are respectively the front view and side view structural schematic diagrams of a lighter flame height automatic adjustment device of the present invention. The automatic adjustment device includes a fixed bottom plate 1, two symmetrical support plates 2 are arranged on both sides of the fixed bottom plate 1, and a top plate 9 is slidably fitted on the top of the two support plates 2, and a flame regulating mechanism is fixed on the top plate 9, and the fixed bottom plate 1 A turntable clamping mechanism for clamping the lighter 4 is provided on the top, and the turntable clamping mechanism and the flame regulating mechanism are connected with a controller; The vertically arranged turntable 3 connected to the main shaft of the control motor 14, the turntable 3 is provided with four gaps evenly distributed in the circumferential direction, and four elastic clips 5 are correspondingly arranged in the four gaps; Detector and the first contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com