A sliding concrete surface flatness test device

A concrete surface and testing device technology, applied in the direction of mechanical roughness/irregularity measurement, etc., to achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

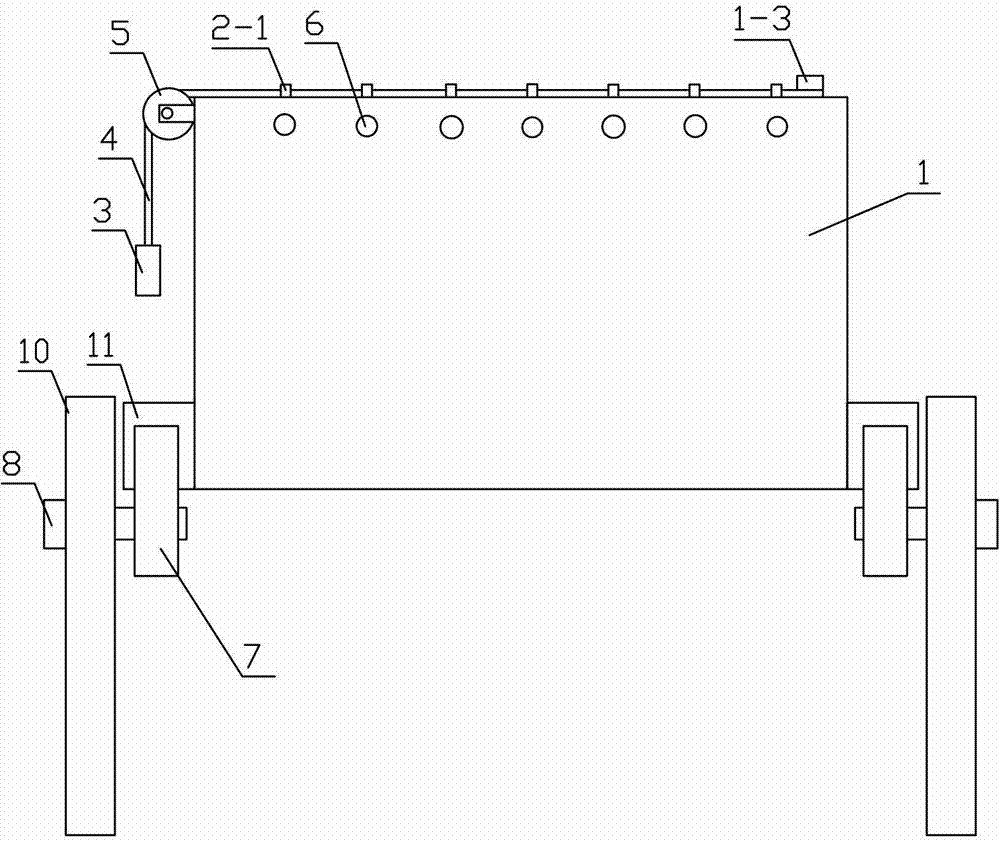

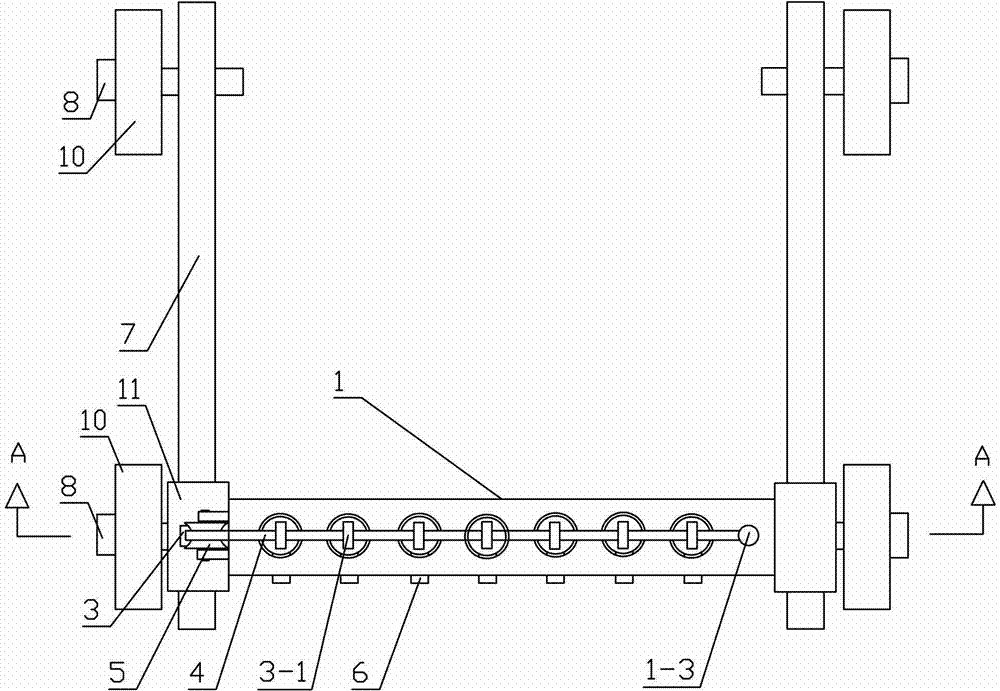

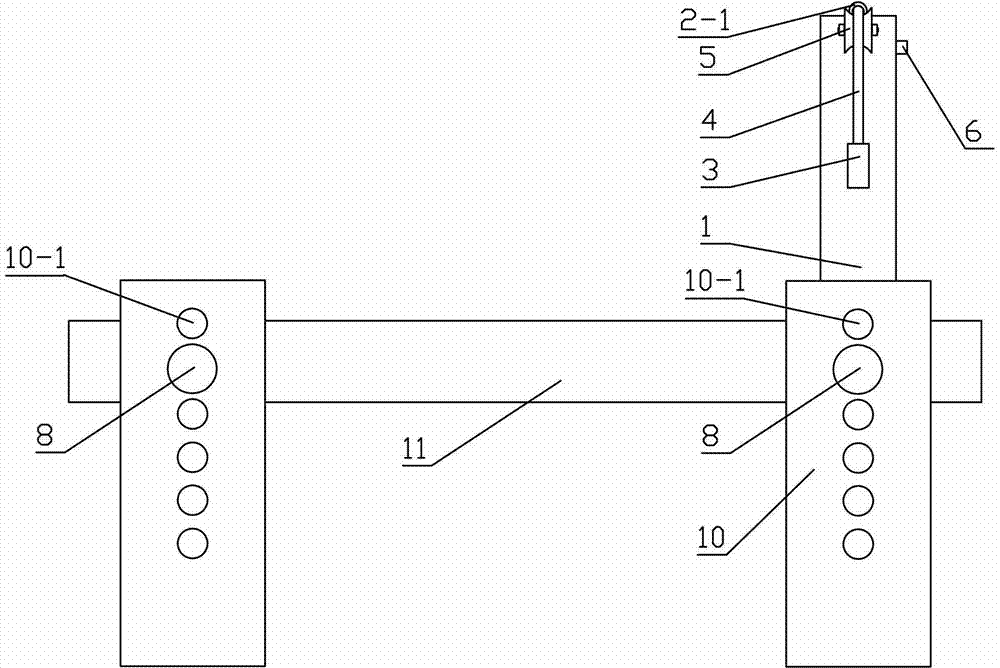

[0013] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Describe this embodiment, a sliding concrete surface smoothness testing device described in this embodiment, the device includes a module 1, a counterweight 3, a rigid rope 4, a pulley 5, a plurality of straight rods 2 and a plurality of positioning pins 6. The module 1 is in the shape of a cuboid, and the upper end of the module 1 is provided with a plurality of rod holes 1-1 vertically penetrating the upper and lower ends of the module 1, and the center lines of the plurality of rod holes 1-1 are on the same vertical plane The inner wall of the upper end of the rod hole 1-1 is provided with a through hole through the front and rear sides of the module 1 or one of the sides, and the upper end of the straight rod 2 is fixedly provided with a lifting ring 2-1. The rods 2 are vertical, and the upper side wall of the straight rod 2 is provided with a pin hol...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 5 , Image 6 with Figure 7Describe this embodiment, a sliding concrete surface smoothness testing device described in this embodiment, characterized in that: the device includes a module 1, two counterweights 3, a rigid rope 4, two pulleys 5, a plurality of Straight rod 2 and a plurality of positioning pins 6, the module 1 is a cuboid shape, the upper end of the module 1 is provided with a plurality of rod holes 1-1 that run through the upper and lower ends of the module 1 in the vertical direction, and the plurality of rod holes 1-1 The center line is on the same vertical plane, and the inner wall of the upper end of the rod hole 1-1 has a through hole through the front and rear sides of the module 1 or one of the sides. The through direction of the 1 ring hole is perpendicular to the straight rod 2, and the upper end side wall of the straight rod 2 is provided with a pin hole 2-2, and each rod hole 1-1 is provid...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 , image 3 , Figure 4 with Figure 7 To illustrate this embodiment, the upper end of the inner ring of the suspension ring 2-1 in this embodiment is in contact with the rigid rope 4, so that the straight rod 2 will drive the counterweight 3 to move upward through the rigid rope 4 as long as it moves downward. , to make the test more accurate, and the other components and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com