Full-automatic SMT net plate thickness measuring method

A thickness measurement, fully automatic technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of measuring the thickness of the stencil single, unable to express the thickness of a specific area, etc., to reduce errors, improve efficiency, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for measuring the thickness of a fully automatic SMT stencil, comprising the following steps:

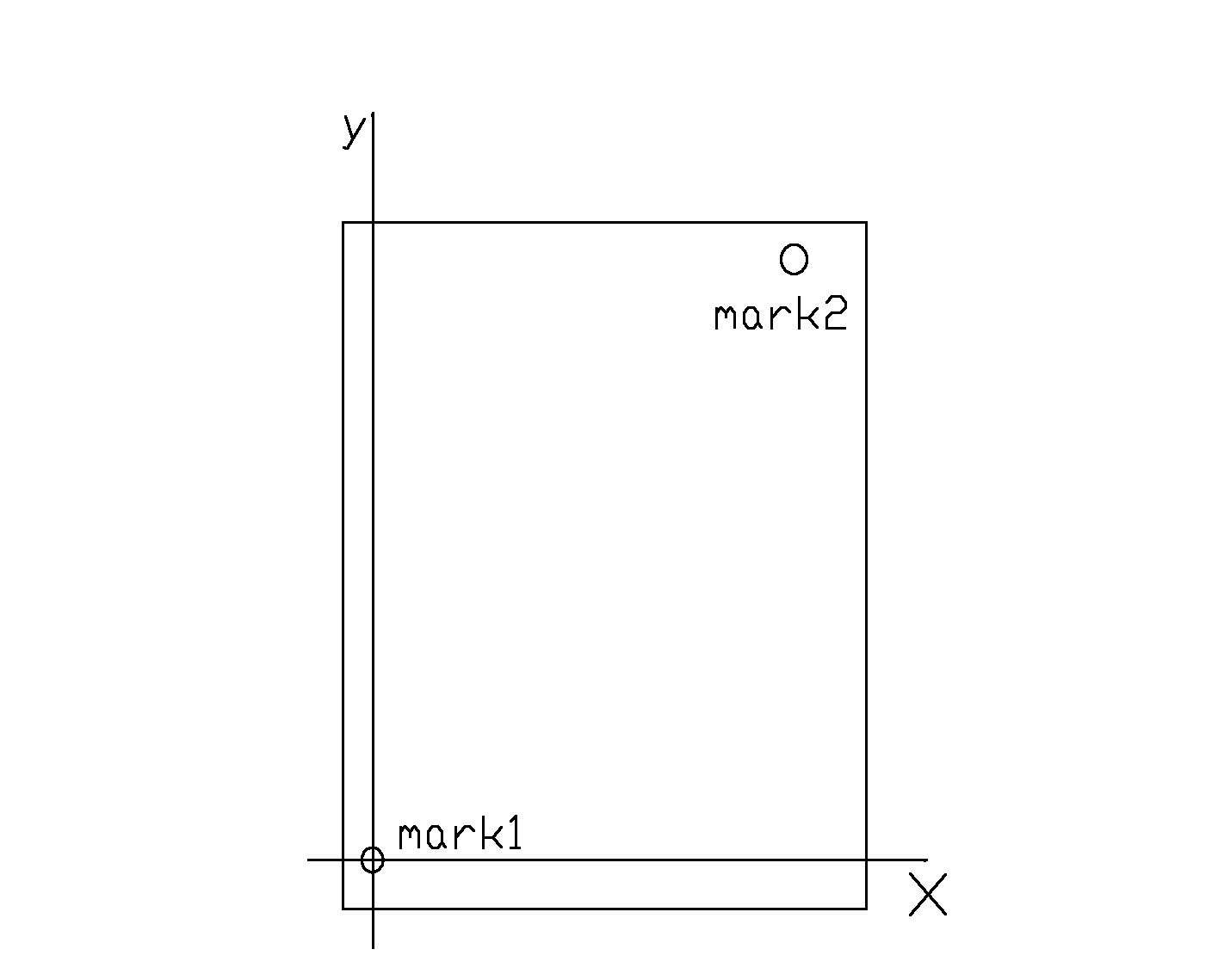

[0025] a) Use laser cutting to make two Mark points at both ends of a diagonal line of the SMT screen, and establish a coordinate system according to their actual positions. The coordinates of Mark1 point are (0,0), and the coordinates of Mark2 point Count as (x,y);

[0026] b) Put the stencil on the thickness measuring workbench, which is equipped with double vertical laser displacement sensors and cameras;

[0027] c) For measurement, first move the camera to the vicinity of the Mark point for automatic identification, record the actual machine coordinates (x1, y1) of the Mark1 point, then move to the second Mark point, and record the machine coordinates (x2, y1) y2);

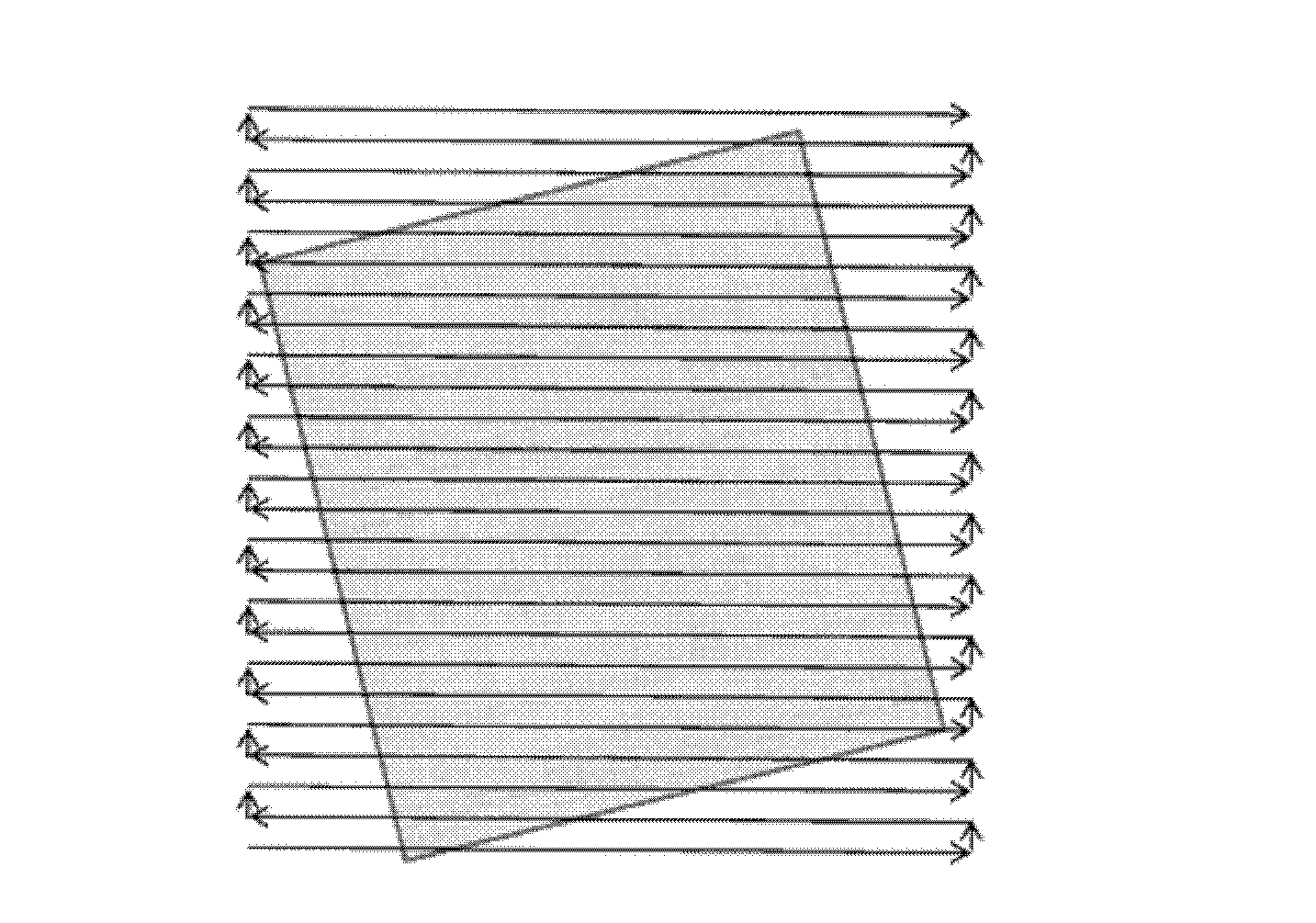

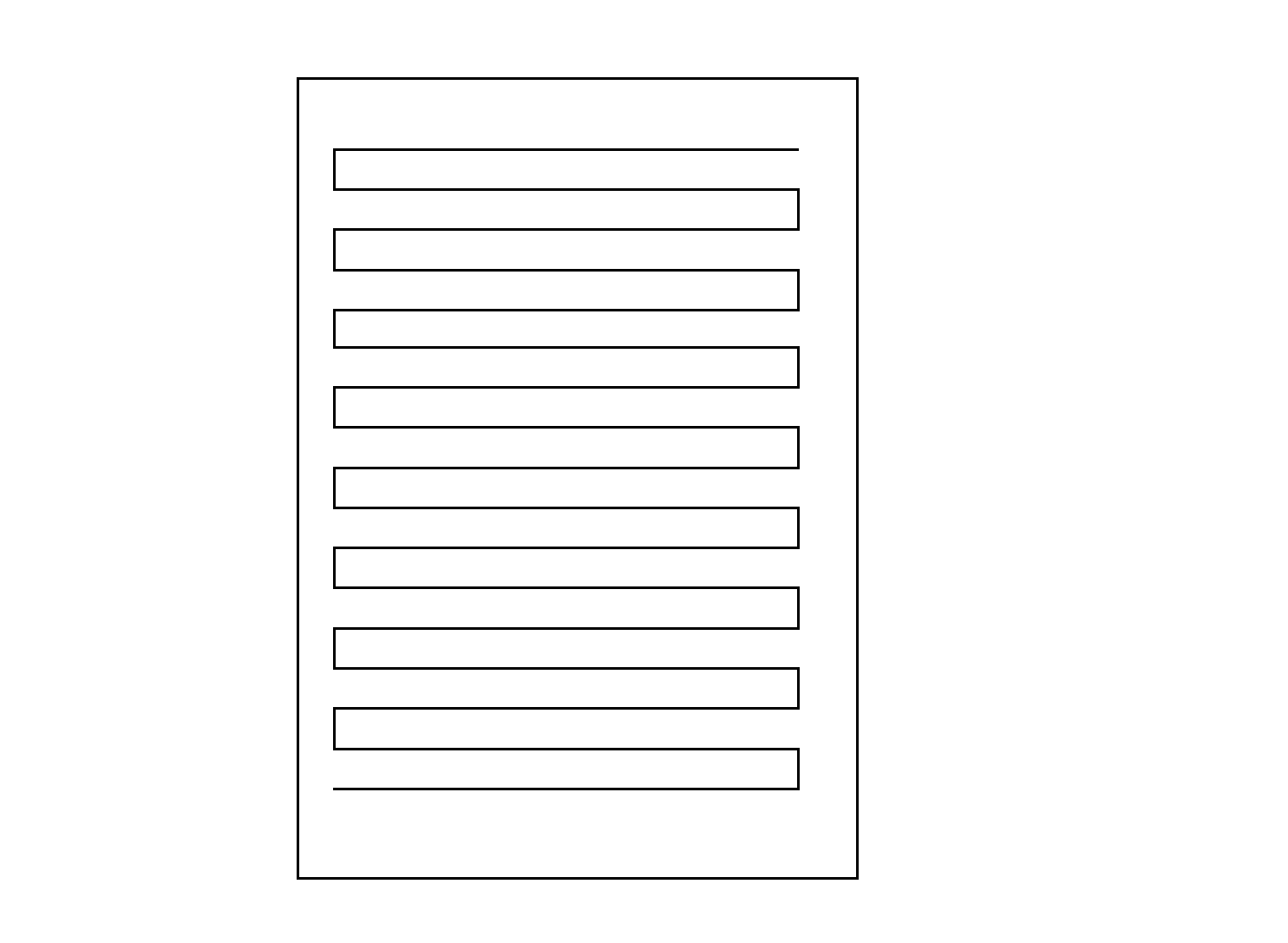

[0028] d) Carry out automatic scanning, and calculate the thickness of the upper plate on the path according to the data obtained by the laser displacement sensor during the scanning process;

[...

Embodiment 2

[0032] This method adopts methods such as making Mark points, automatically identifying Mark points, and alignment to generate thickness map information corresponding to the stencil. First of all, it is necessary to use laser cutting to make two Mark points at both ends of a diagonal line of the SMT stencil and establish a coordinate system according to their actual positions, such as figure 2 As shown, the coordinates of the Mark1 point are (0,0), and the coordinates of the Mark2 point are (x,y).

[0033] Put the stencil on the thickness measurement workbench, which is equipped with a double vertical laser displacement sensor and a camera. When starting the measurement, first move the camera to the vicinity of the Mark point for automatic identification and record the position of the Mark1 point on the actual machine coordinates (x1, y1), then move to the second Mark point, and also record the machine coordinates (x2, y2).

[0034] Then start automatic scanning. During the ...

Embodiment 3

[0039] A fully automatic SMT stencil thickness measurement method, including the following steps: a) Use laser cutting to make two Mark points at both ends of a diagonal line of the SMT stencil, and establish a coordinate system based on their actual positions , the coordinates of Mark1 point are (0,0), and the coordinates of Mark2 point are (x,y); b) Put the stencil on the thickness measuring table, which is equipped with double vertical laser displacement sensors and the camera; c) to measure, first move the camera to the vicinity of the Mark point for automatic identification, record the actual machine coordinates (x1, y1) of the Mark1 point, then move to the second Mark point, and record the machine coordinates as well (x2, y2); d) Carry out automatic scanning, calculate the thickness of the upper plate on the path according to the data obtained by the laser displacement sensor during the scanning process; e) perform alignment operation according to the obtained virtual coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com