Inkjet printing device

An inkjet printing device and inkjet head technology, applied in printing and other directions, can solve the problems of peeling off the waterproof layer on the surface of the nozzle and rising ink cost, and achieve the effects of inhibiting peeling, inhibiting corrosion, and inhibiting ink oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

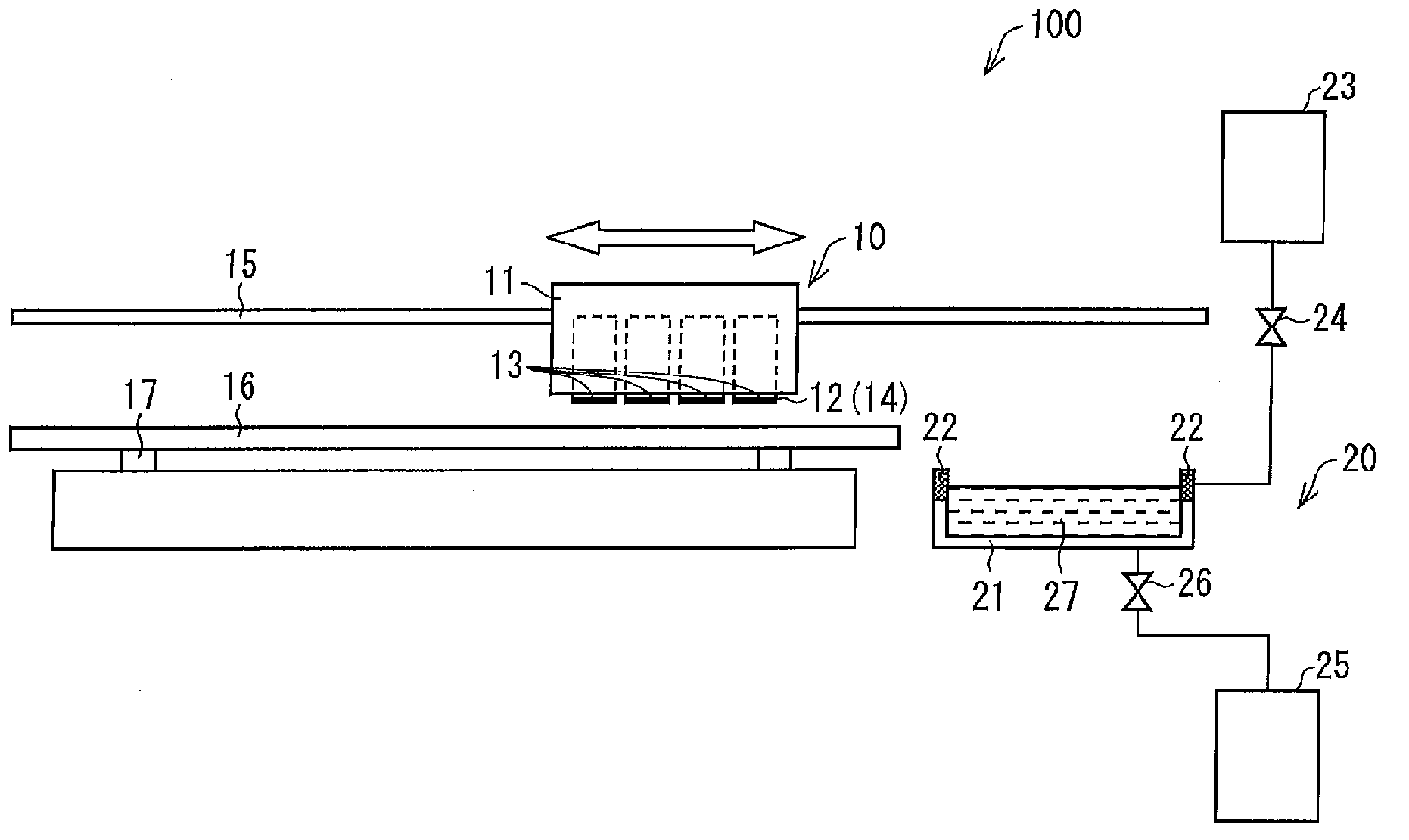

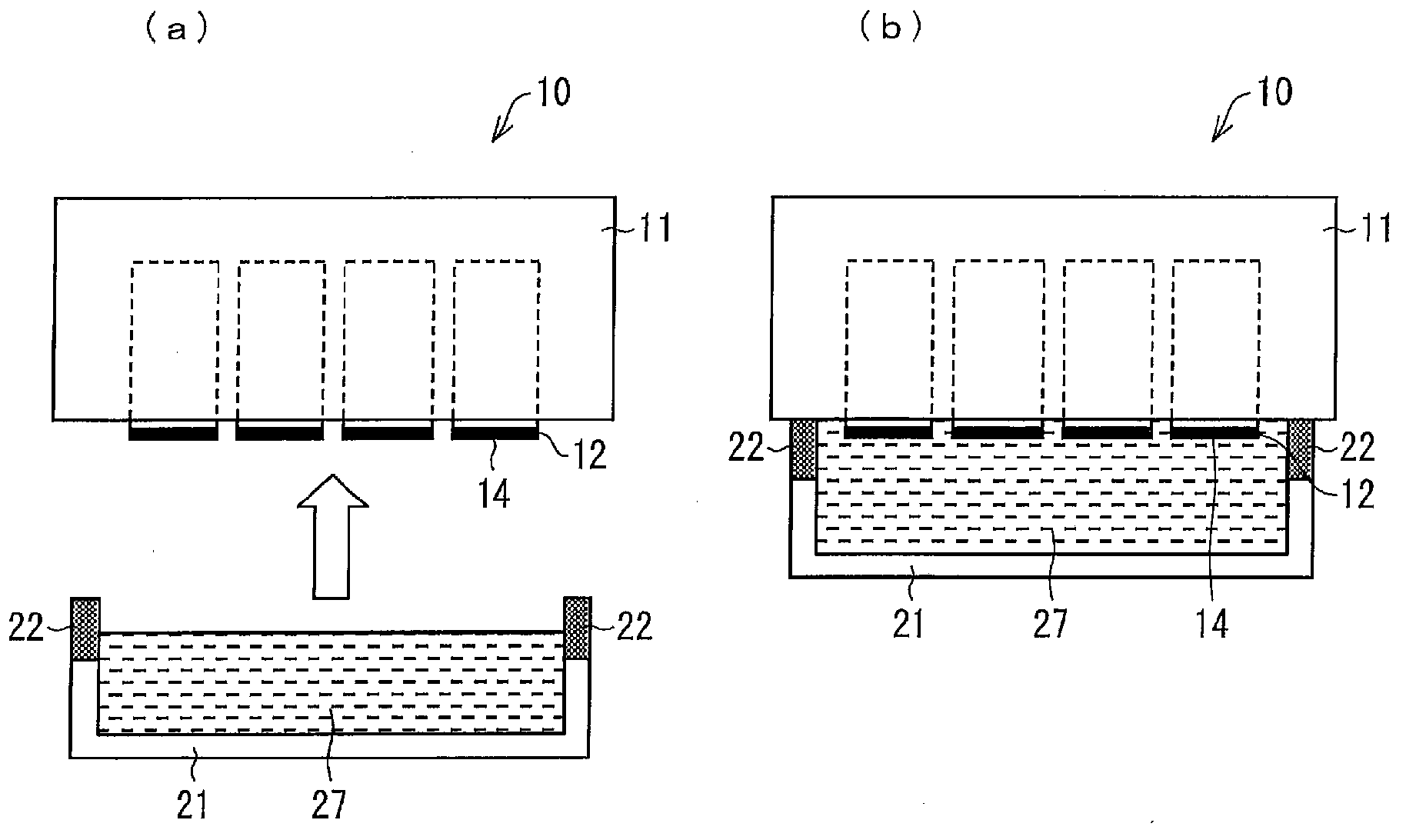

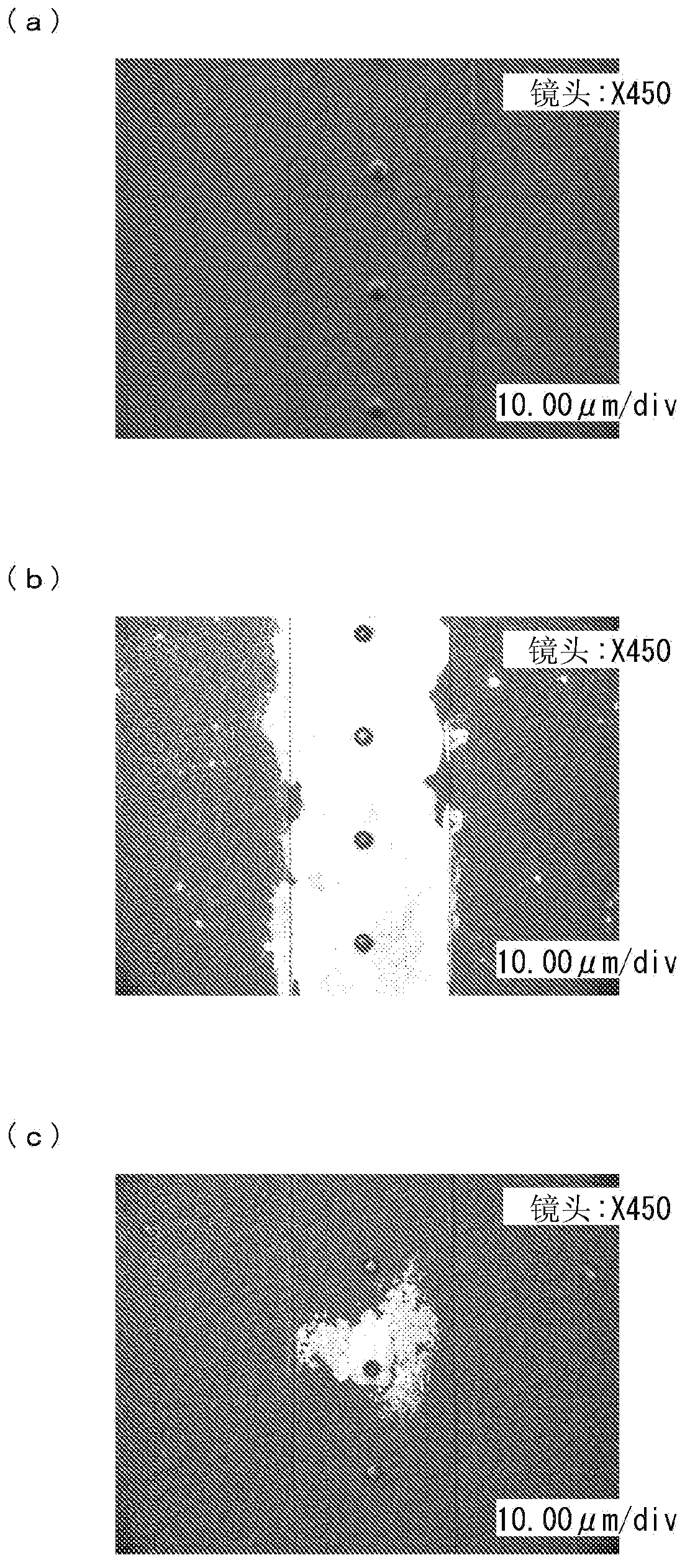

[0066] As an example, using the inkjet printing apparatus 100 of the present invention, in an environment with a temperature of 45° C. and a humidity of 90%, after leaving the inkjet head 10 in a printing stop state for 7 days, its nozzle surface 14 was tested. observe. In the embodiment, the state of immersing the nozzle surface 14 in the protective liquid 27 inside the cap 21 is maintained during the stop of printing of the inkjet head 10 .

[0067] On the other hand, as a comparative example, using the same mechanism as the inkjet printing apparatus 100 of the present invention, under the same environment, the nozzle surface 14 was observed after the inkjet head 10 was left for 7 days with the printing stopped. . In the comparative example, the protection mechanism 20 was not used, and the state in which the nozzle surface 14 was exposed to the atmosphere was kept unchanged during the printing stop of the inkjet head 10 .

[0068] In addition, in Examples and Comparative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com