Lithium battery positive electrode material, preparation method thereof, lithium battery, and positive electrode piece of lithium battery

A cathode material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow lithium diffusion and charge transfer, poor low temperature performance, affecting battery efficiency, etc., to achieve excellent conductive nodes and improve low temperature performance. , the effect of excellent conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Further, the present invention also provides a method for preparing the positive electrode sheet of the above-mentioned lithium battery, comprising the following steps:

[0032] Add lithium active material, surfactant and oxidant into water, ultrasonically disperse, then add conductive polymer glue and conductive carbon, continue ultrasonically disperse, filter, wash, and vacuum dry the product at 100°C-160°C for 12h-24h.

[0033] Further, the present invention also provides a positive electrode sheet for a lithium battery, which contains the positive electrode material for a lithium battery in any of the above examples, a negative electrode sheet, and an electrolyte.

[0034] In one example, the lithium battery positive sheet also contains a positive electrode binder and a positive electrode conductive agent.

[0035] Still further, the present invention also provides a lithium battery, which includes the above-mentioned positive electrode sheet of the lithium battery....

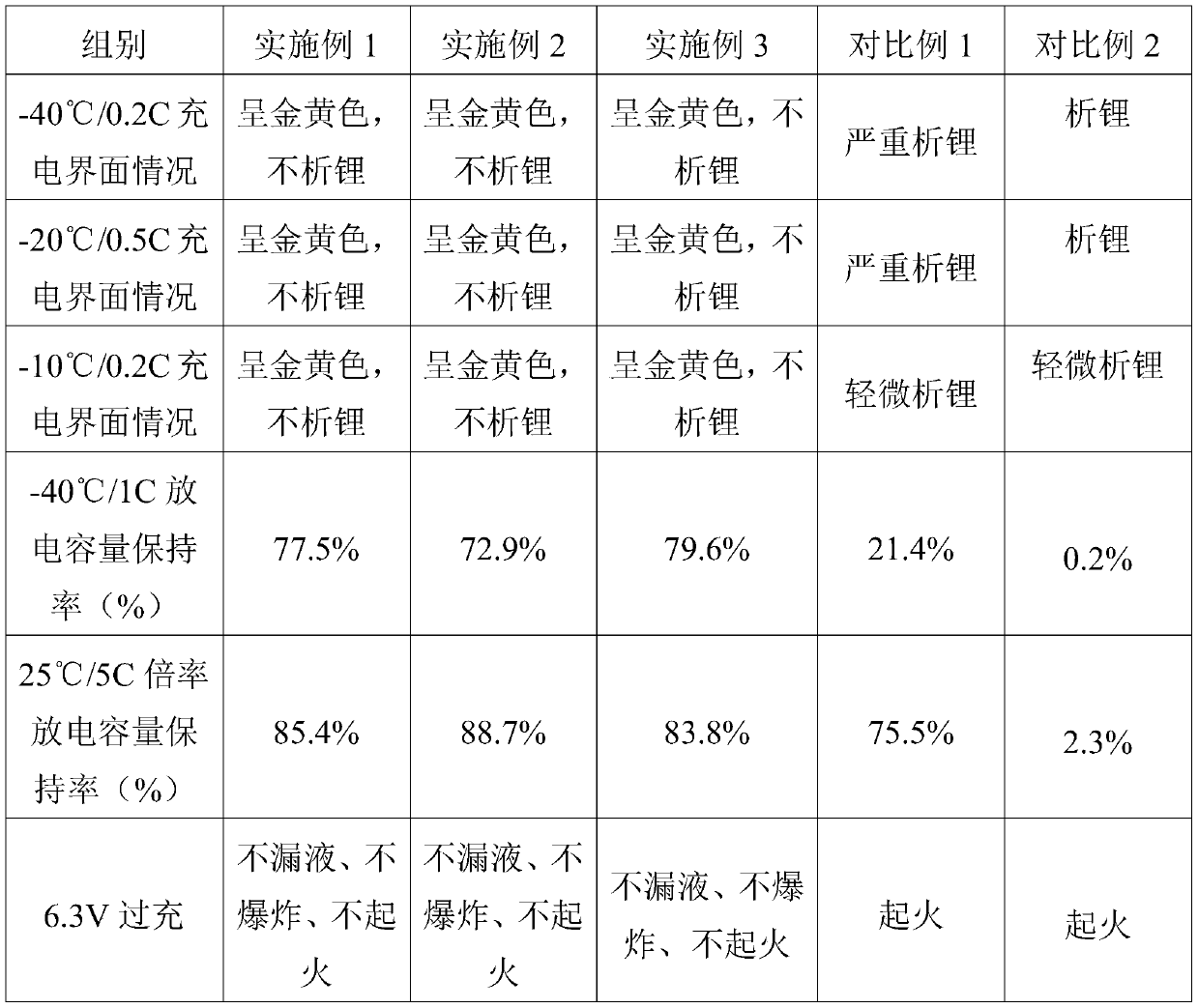

Embodiment 1

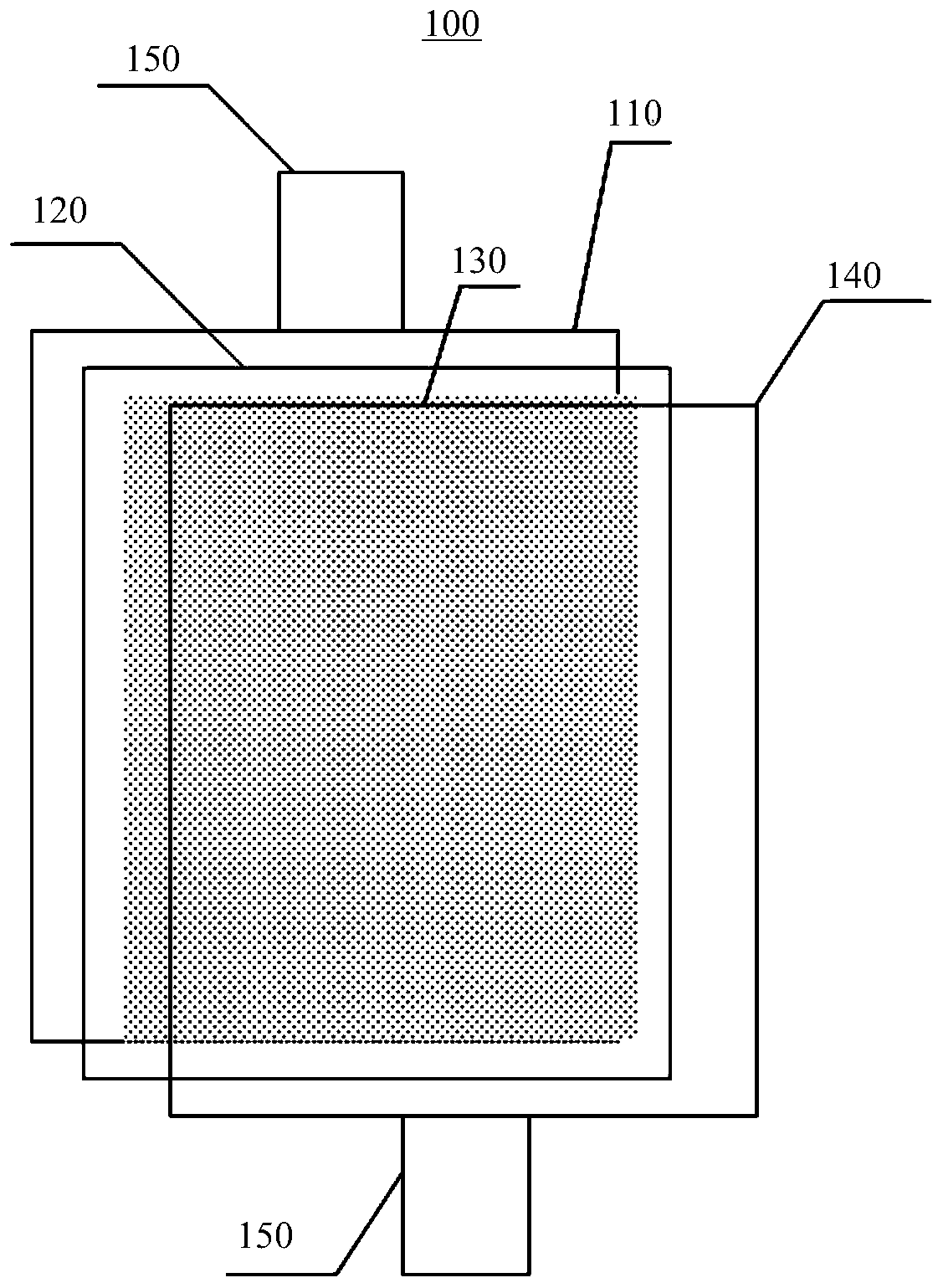

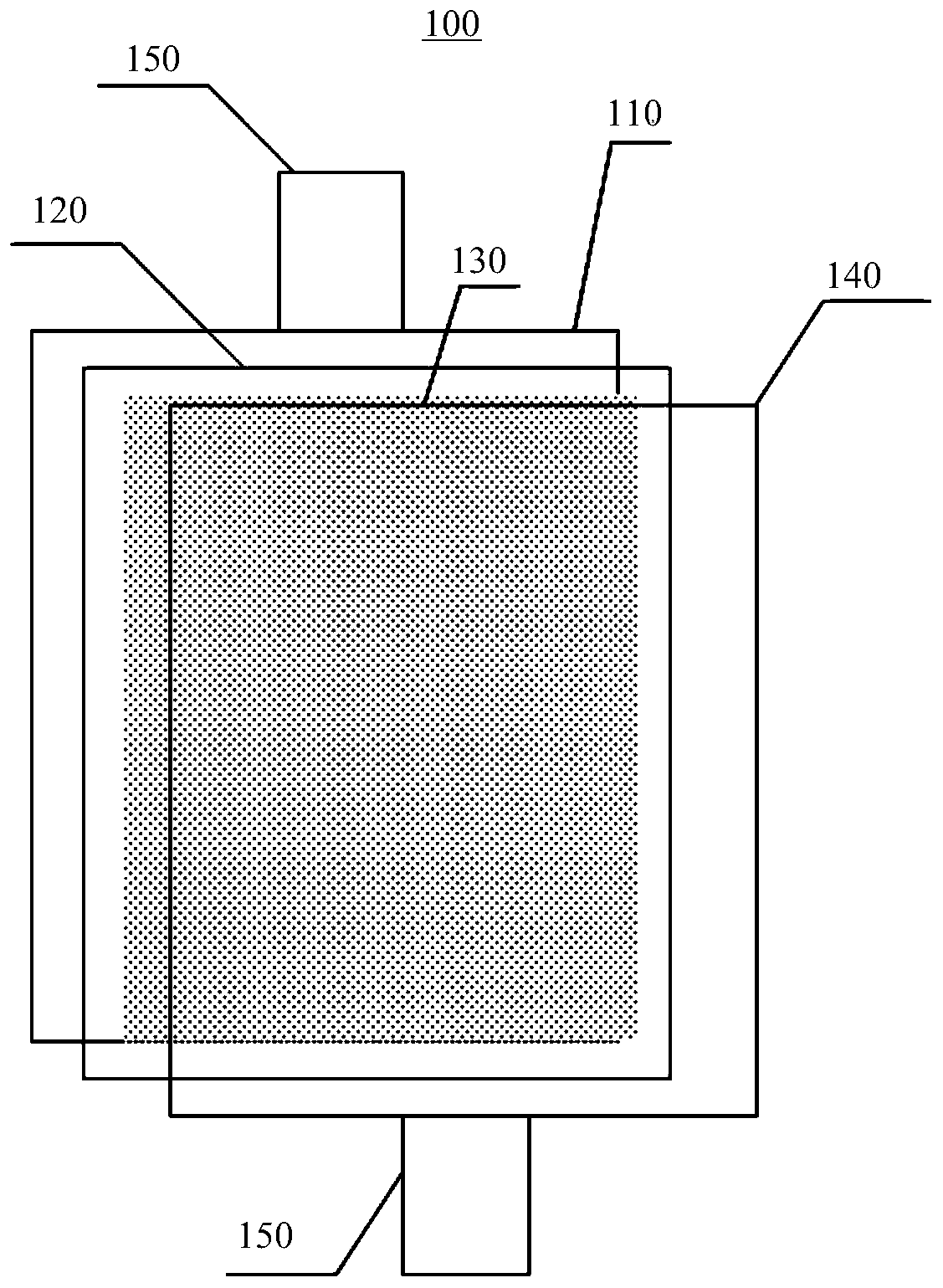

[0052] The lithium battery of this embodiment includes a positive electrode sheet, an electrolyte, a separator, a negative electrode sheet, and tabs.

[0053] Positive electrode sheet: including lithium battery positive electrode material, positive electrode binder and positive electrode conductive agent. The lithium active material in the positive electrode material of the lithium battery is a ternary nickel-cobalt lithium manganese oxide material whose morphology is agglomerates and single crystals, wherein the mass fraction of the agglomerates is 60%. The median particle size (D50) of the agglomerates is 4 μm, and the primary particle size is 550 nm; the median particle size (D50) of the quasi-single crystal is 8 μm. The specific surface area of lithium active material is 0.5m 2 / g, the tap density is 1.5g / cm 3 . The outer surface of the ternary nickel cobalt lithium manganate material is covered with a composite conductive layer. The composite conductive polymer is co...

Embodiment 2

[0059] The difference between the lithium battery of this embodiment and Embodiment 1 is that the composition of the positive electrode sheet, the negative electrode sheet, and the electrolyte is as follows:

[0060] Positive electrode sheet: including lithium battery positive electrode material, positive electrode binder and positive electrode conductive agent. The lithium active material in the positive electrode material of the lithium battery is a ternary nickel-cobalt lithium manganese oxide material whose morphology is agglomerates and single crystals, wherein the mass fraction of the agglomerates is 30%. The median particle size (D50) of the agglomerates is 3 μm, and the primary particle size is 300 nm; the median particle size (D50) of the quasi-single crystal is 7 μm. The specific surface area of the lithium active material is 0.7m 2 / g, the tap density is 1.65g / cm 3 . The outer surface of the ternary nickel cobalt lithium manganate material is covered with a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com