Corrosive negative ion removal apparatus and regeneration method of negative ion exchange resin

A technology for exchanging resins and anions, which is applied in ion exchange mediation/control, ion exchange water/sewage treatment, ion exchange bed cleaning/flushing, etc. It can solve problems such as promoting corrosion of metal materials, corrosion, and problems with anti-corrosion countermeasures. To achieve the effect of prolonging the service life, saving water resources and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

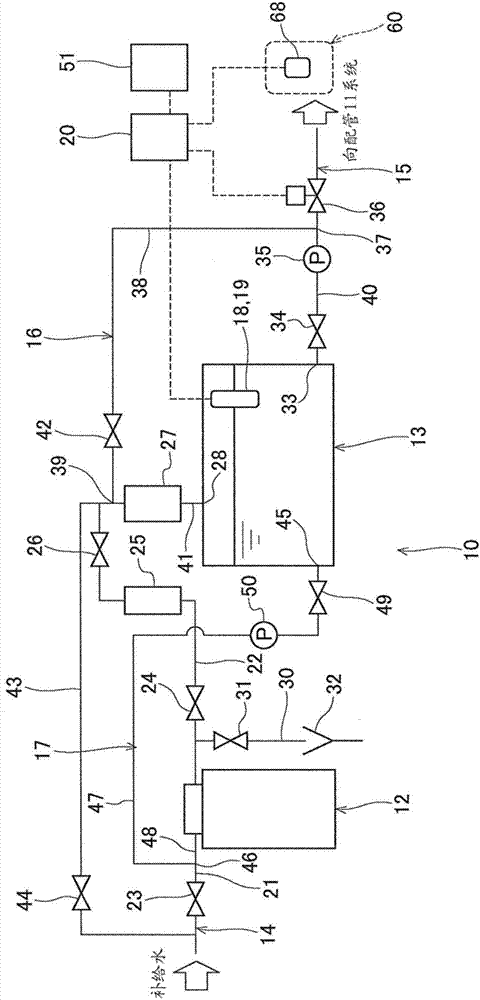

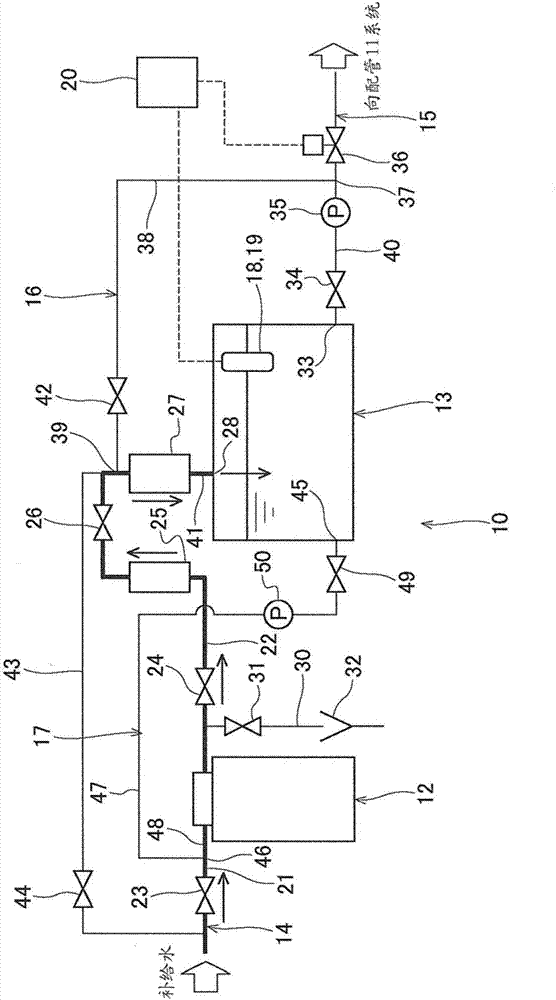

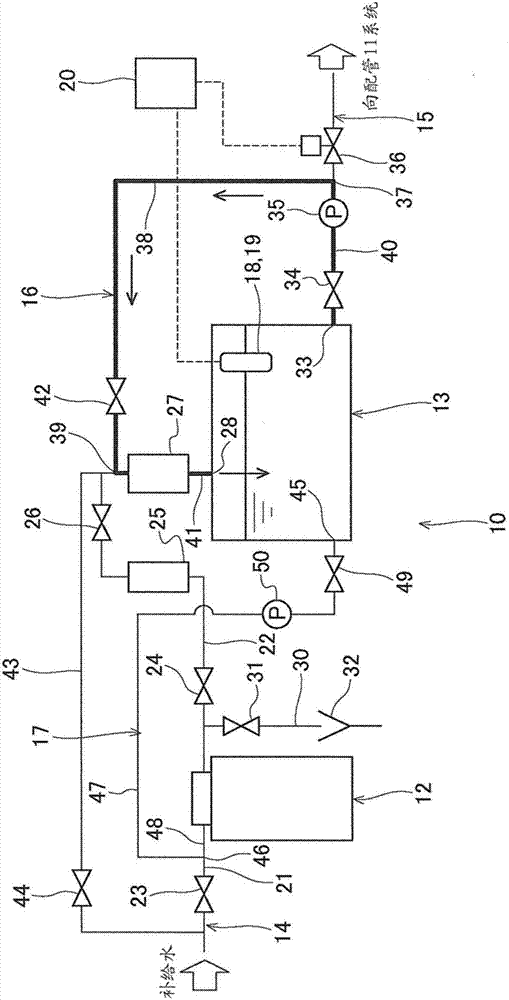

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, the case where the corrosive anion removal apparatus concerning this invention is applied to the piping made of carbon steel pipes or galvanized steel pipes for air-conditioning equipment is demonstrated as an example.

[0031] First, according to figure 1 The structure of the corrosive anion removal apparatus 10 which concerns on embodiment of this invention is demonstrated. figure 1 is a schematic diagram showing the corrosive anion removal device 10 .

[0032] Such as figure 1 As shown, the structure of the corrosive anion removal device 10 according to the embodiment of the present invention has: an anion exchange resin 12 that generates anion exchange treated water that is not easily corroded; a treatment water tank 13 that stores anions generated by the anion exchange resin 12 Exchange treatment water; anion exchange tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com