Moisture control method for airflow cut-tobacco drier

A control method and the technology of the silk drying machine, which are applied in the direction of preparing tobacco, tobacco, and processing tobacco, etc., can solve the problems of large fluctuations in outlet moisture, improve the moisture control ability of the airflow type silk drying machine, and reverse temperature fluctuations, etc., to achieve improved The effect of processing quality, strengthening the process control ability of equipment, and reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The process requirements of this embodiment: the process gas temperature is 225±3°C, and the outlet moisture is 13.2±1%.

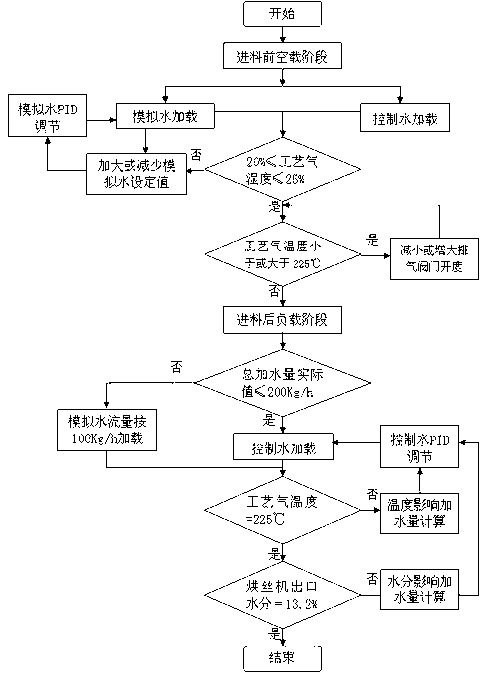

[0020] see figure 1 Shown, the moisture control method of the airflow type wire drying machine of the present invention:

[0021] When the airflow drying machine is in the no-load stage before feeding, the control water is loaded according to the set value of 200Kg / h constant flow rate, and the simulated water is loaded according to the initial set value of 500Kg / h flow rate. When the relative humidity of the process gas is 25%, the set value of the simulated water is increased or decreased respectively through the simulated water PID regulator. When 20%≤the relative humidity of the process gas≤25%, Keep the original simulated water setpoint. When the process gas temperature is 228°C, reduce or increase the opening of the exhaust valve respectively. When the temperature of the process gas is within the range of 222°C to 228°C and the relative hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com