Automatic paper box and bottle unloading machine

A carton and automatic technology, applied in the direction of packaging bottles, packaging, packaging items, etc., can solve the problems of high manufacturing cost, complex structure, large volume, etc., achieve good work stability, simple structure, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

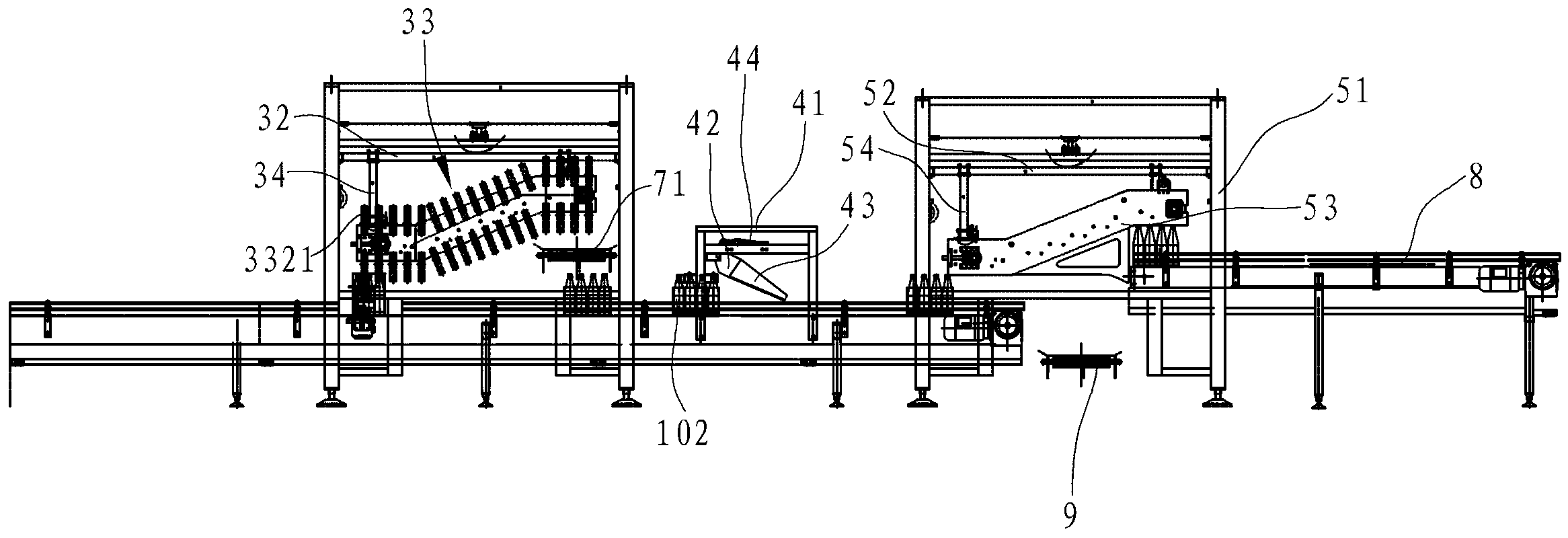

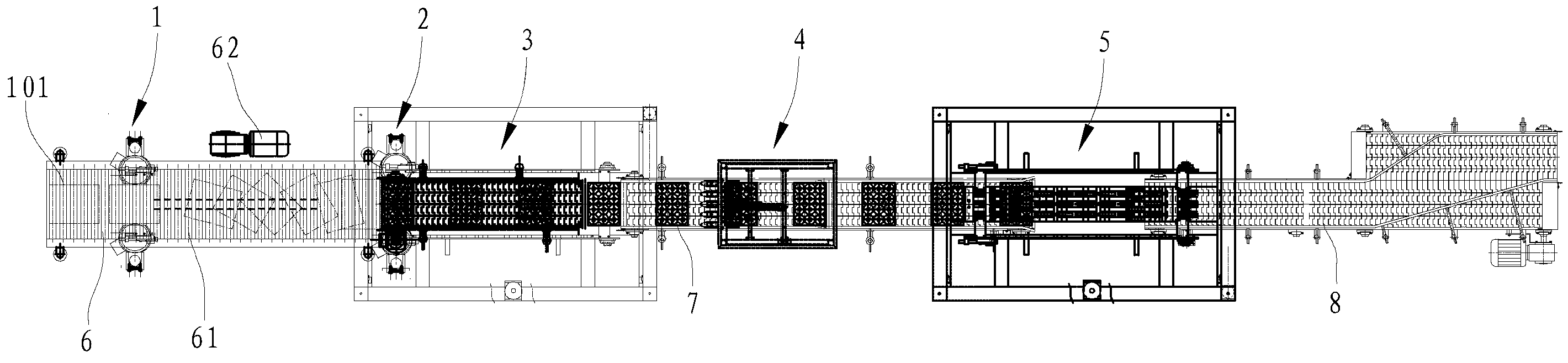

[0024] see figure 1 and figure 2 , an automatic carton bottle unloading machine, comprising a first carton cutting machine 1, a second carton cutting machine 2, a carton clamping machine 3, a carton cutting machine 4 and a bottle case separator 5 arranged in sequence.

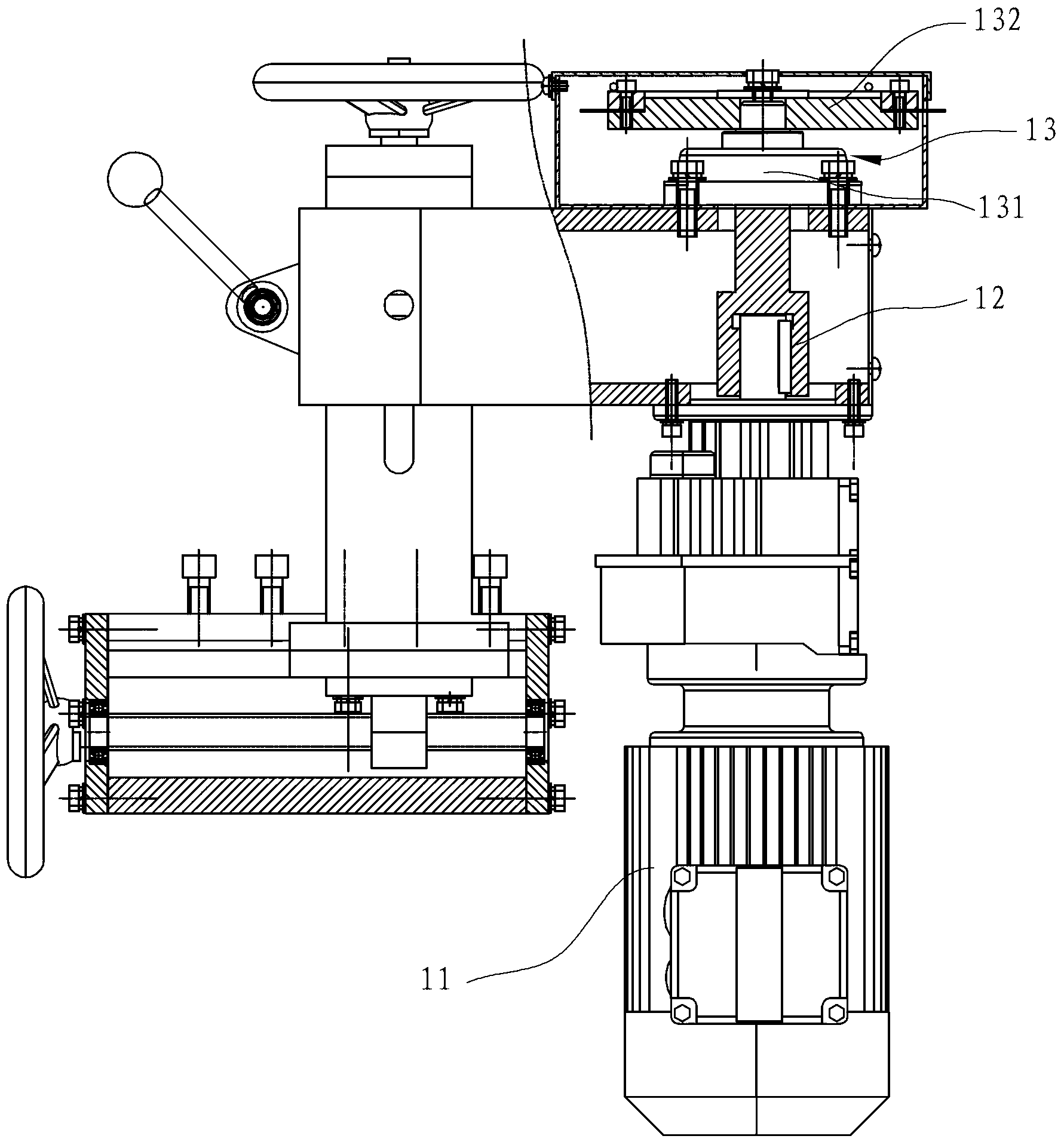

[0025] The first box cutting machine 1 comprises two, is symmetrically arranged on the both sides of the first box conveyor belt 6, see image 3 , the first cutting box machine 1 can adopt the existing technology, including the first motor 11, the output shaft of the first motor 11 is connected with the tool rest assembly 13 through the connecting shaft 12, and the tool rest assembly 13 includes a square frame fixed with the connecting shaft 12 The seat 131 and the disc 132 fixed to the square seat 131 , the disc 132 is provided with a plurality of blades at intervals in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com