Multi-station processing paper plastic packaging machine

A multi-station, packaging machine technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

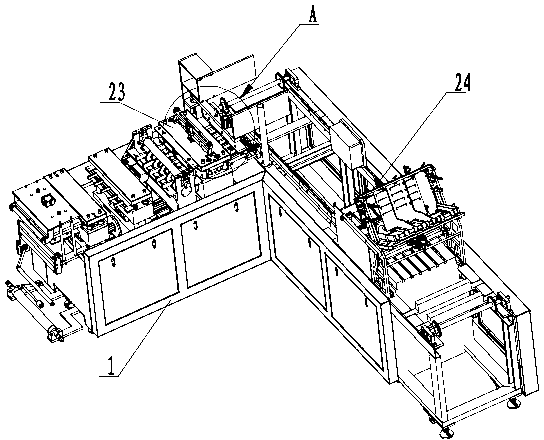

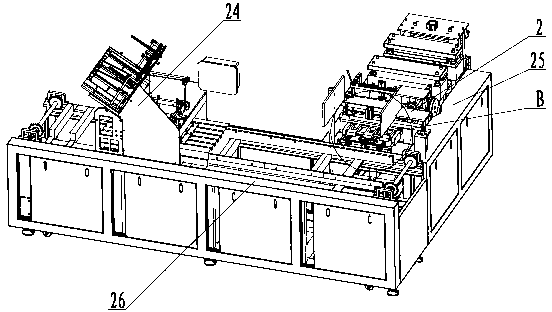

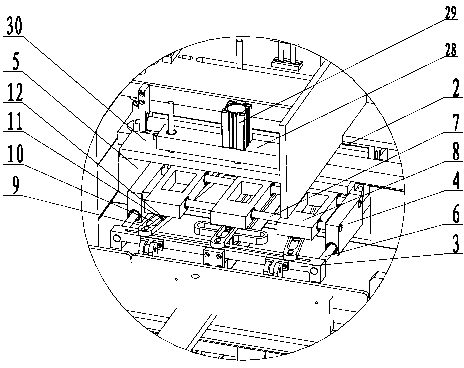

[0019] As shown in the figure, a multi-station processing paper-plastic packaging machine includes a support 1, a forming device 22, a punching device 23 and a heat-sealing device 24, the punching device 23 includes a blanking area, and the support 1 There is a material receiving mechanism that matches the blanking area, the support 1 includes a horizontal part 25 and a vertical part 26 that are perpendicular to each other, and the forming device 22 and the punching device 23 are arranged on the horizontal part 25, the heat sealing device 24 is set on the vertical part 26, and the horizontal part 25 is provided with a transfer mechanism, the transfer mechanism includes a motor 27, a rotating plate 28, a power transmission mechanism 29 and a suction plate 30 , the power transmission mechanism is an air cylinder or a hydraulic cylinder, the motor 27 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com