Edible instant flour bag packaging film and preparation method thereof

A packaging film and flour technology, applied in the field of edible packaging bags, can solve the problems that the large-scale production of instant noodle seasoning powder packets cannot be promoted, the mechanical performance is not high, and the production cost is high, so as to achieve large-scale production, low production cost, good mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Take 1 g of potato starch, 0.1 g of sodium carboxymethyl cellulose, and 0.1 g of glycerol, add deionized water to 100 ml, and then uniformly stir at 50° C. for 15 minutes for gelatinization, and put the gelatinized starch paste on the Cast film on a glass plate with plastic wrap, and dry at 50°C for 0.5 hour to form a film.

Embodiment 2

[0024] Example 2: Take 10g of potato starch, 5g of sodium carboxymethyl cellulose, and 10g of glycerin, add deionized water to 100ml, and then stir evenly at 100°C for 40 minutes to gelatinize, and spread the gelatinized starch paste to keep fresh The film was flow-coated on a glass plate, and dried at 120° C. for 2 hours to form a film.

Embodiment 3

[0025] Example 3: Take 5g of potato starch, 0.3g of sodium carboxymethyl cellulose, and 2g of glycerin, add deionized water to 100ml, and then stir evenly at 75°C for 25 minutes for gelatinization, and spread the gelatinized starch paste Cast a film on a glass plate with plastic wrap, and dry it at 80°C for 1 hour to form a film.

PUM

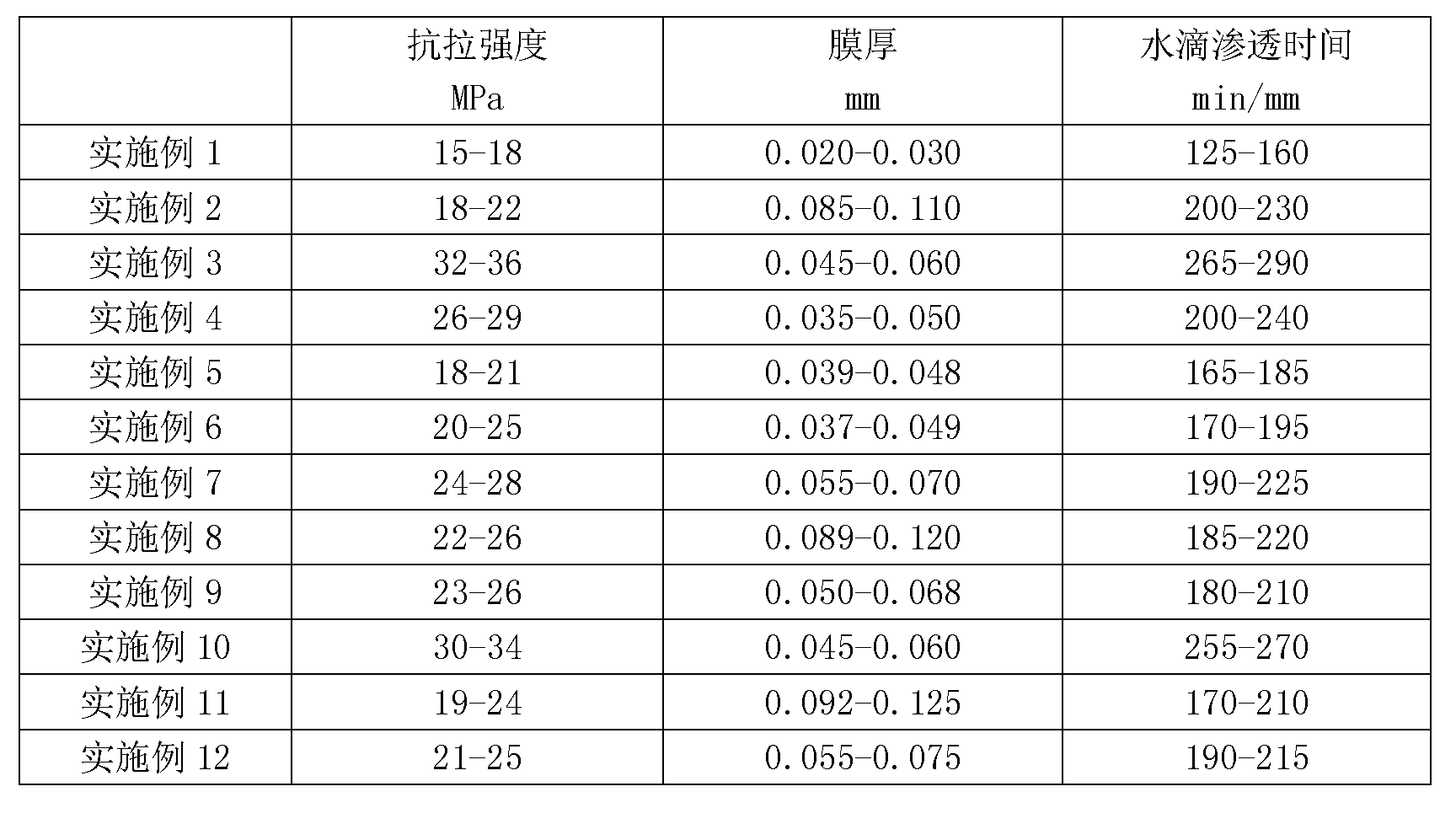

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap