Yarn humidifier

A technology of humidifier and thread yarn, which is applied in the direction of spraying/jetting textile materials, etc., which can solve the problems of low efficiency, expensive equipment, deformation of paper core, etc., and achieve the effect of accurate adjustment, fast speed and high humidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

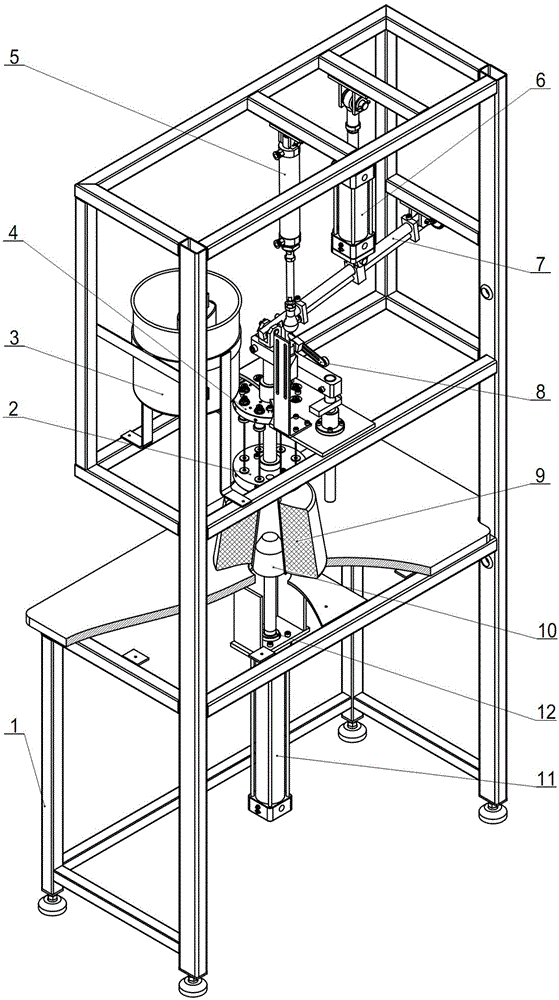

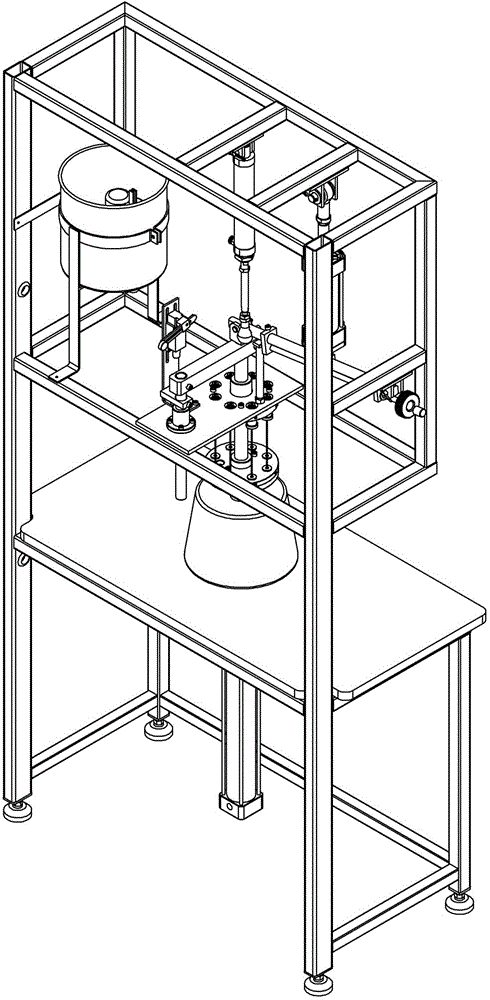

[0029] Such as Figure 1-11 As shown, the yarn humidifier includes a frame assembly 1, a guide system 2, a water storage system 3, an injection system 4, a lever system 7 and a positioning system 12, and the guide system 2, water storage system 1 is installed on the frame assembly 1 System 3, injection system 4, lever system 7 and positioning system 12 constitute a yarn humidifier.

[0030] Among them, the frame assembly 1 includes a frame 1-1, a platen 1-2, a liquid injection seat fixing plate 1-3, a connection ear 1-4 on the reset cylinder, a connection ear 1-5 on the water injection cylinder, and a lever left connection Ear 1-6 and secondary guide sleeve 1-7, install platen 1-2 in the middle of frame 1-1, set positioning core insertion hole in the center of platen 1-2, place platen on frame 1-1 Door panels are installed above 1-2 to form a closed cabinet, and the liquid injection seat fixing plate 1-3 is installed on the bottom of the closed cabinet. On the liquid seat fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com