An intelligent oil pan assembly for a diesel engine and its application method

An oil pan, intelligent technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of inability to accurately monitor the oil level, and achieve the effect of accurately monitoring the oil level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

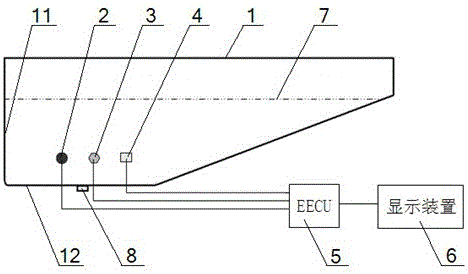

[0057] see figure 1 , an intelligent oil pan assembly for a diesel engine, comprising an oil pan shell 1, a processor 5 and a display device 6, the oil pan shell 1 is provided with an oil quality sensor 2, a temperature sensor 3, a liquid The level sensor 4, the liquid level sensor 4 is a pressure type liquid level sensor, the processor 5 is an engine control unit EECU, the oil quality sensor 2, the temperature sensor 3, the liquid level sensor 4 and the processor 5 is connected to the input end of the processor 5, and the output end of the processor 5 is connected to the display device 6; the oil quality sensor 2, temperature sensor 3, and liquid level sensor 4 are all arranged at the deep end 11 of the oil pan shell side, and the distances between the oil quality sensor 2, the temperature sensor 3, the liquid level sensor 4 and the bottom 12 of the oil pan shell 1 are all equal, and the distances between the oil quality sensor 2, the bottom 12 and The ratio of the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com