Probes and Connection Fixtures

A technology for connecting fixtures and probes, which is applied in the direction of measuring devices, instruments, and measuring electronics. It can solve problems such as probe preload deviation and compression size deviation, and achieve the effect of suppressing reaction force and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0044]

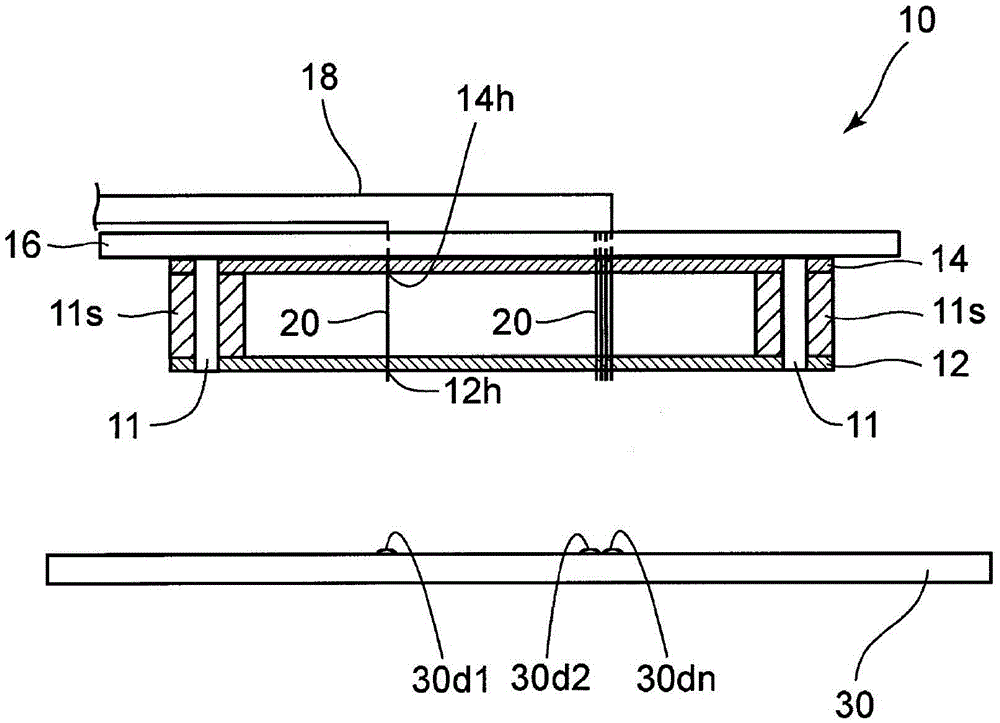

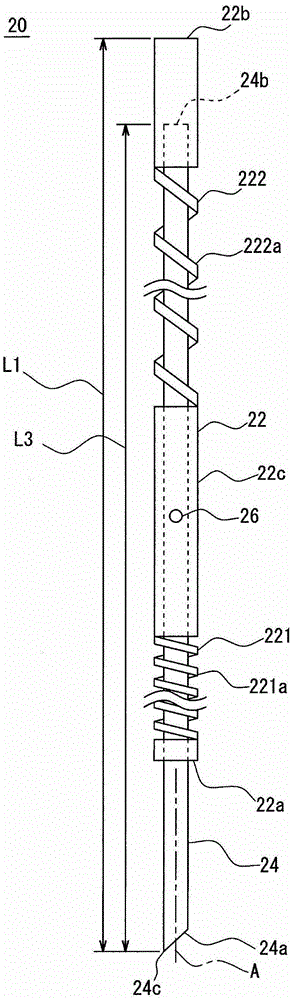

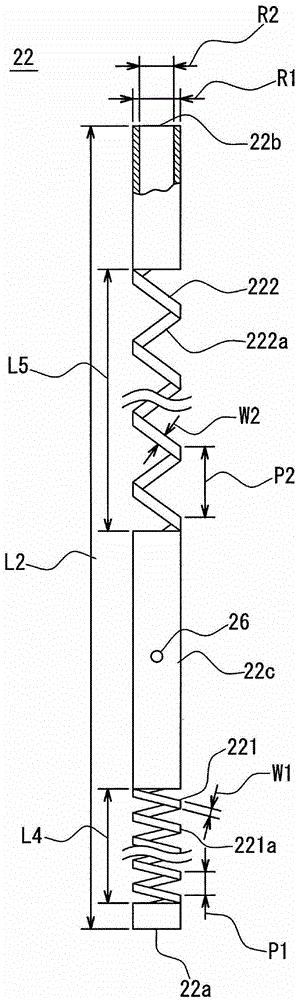

[0045] refer to figure 1 , the schematic configuration of the connection jig using the probe according to the first embodiment of the present invention will be described. The connection jig 10 includes a first probe holding member 12 , a second probe holding member 14 , and an electrode portion 15 (refer to Figure 5 ) and the electrode holding member 16. The first and second probe holding members 12 and 14 are formed of insulating plate-like members such as resin or ceramics. The first and second probe holding members 12 and 14 are held at a predetermined distance by the rod-shaped support member 11 and the spacer 11s attached around the rod-shaped support member 11 .

[0046] The first probe holding member 12 is formed with a plurality of through holes 12h corresponding to the first through holes according to the present invention, and the distal end portion of the probe 20 inserted into the plurality of through holes 12h and held is guided to a predetermined po...

no. 2 approach

[0086] refer to Figure 7 and Figure 8 , the probe according to the second embodiment of the present invention will be described. like Figure 7 and Figure 8 As shown, the probe 40 includes: an outer conductor 41 , an inner conductor 42 and a fixing portion 43 .

[0087] The outer conductor 41 is electrically conductive and has a substantially cylindrical form (cylindrical form in this embodiment). The inner conductor 42 is electrically conductive and has a substantially cylindrical shape (cylindrical shape in this embodiment), and has a sharp abutment end 42c at its front end 42a that abuts on a connection point of the inspection object. Such an inner conductor 42 is inserted into the outer conductor 41 in such a manner that its front end portion 42 a protrudes from the front end side of the outer conductor 41 and its rear end portion 42 b does not protrude from the rear end side of the outer conductor 41 , and the inner conductor 42 is in contact with the outer conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com