Control module and method for producing same

A control module, electronic control technology, applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problem of huge, expensive and expensive flexible conductive foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

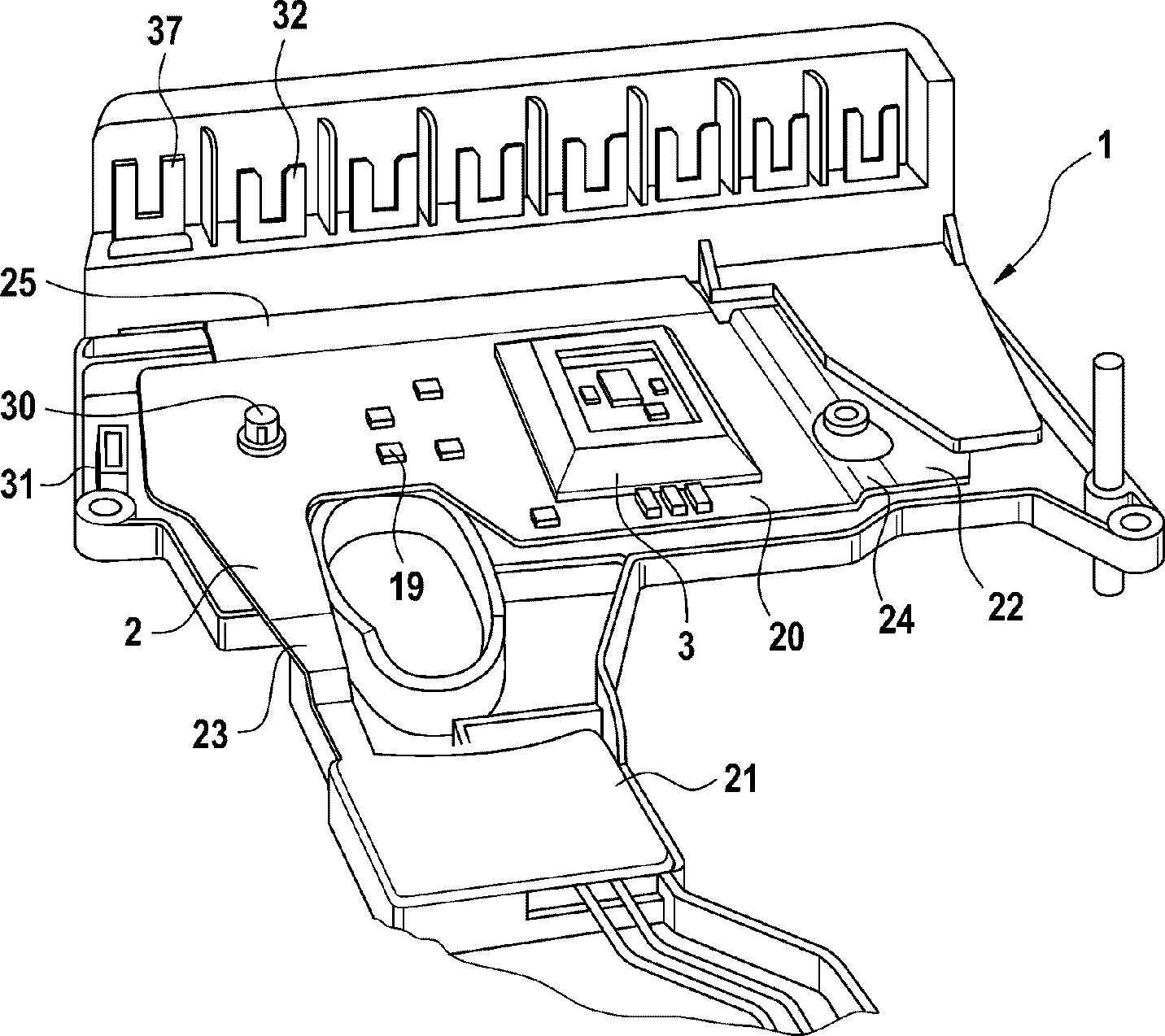

[0032]FIG. 1 schematically shows a control module which can preferably be used in an automatic transmission of a motor vehicle. Although the transmission control module is described here as an example, the control module can also be used to actuate other devices, wherein of course the control module must be adapted to the corresponding required framework conditions, such as actuators to be actuated, sensors and the number and type of connectors. The transmission control module 1 shown here has, for example, a complex plastic part as a base carrier 1 , in which contacts in the form of metal blade contacts are used to actuate actuators, for example electrohydraulic pressure control valves. The feed-through element 32 can be introduced directly into the base body 1 . Arranged on the base body 1 is a circuit board 2 , which is the basic carrier of the electrical connection technology. The circuit board 2 is used to electrically connect the different electrical components of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com