Cuttings collecting device with auger mechanism

A collection device and cutting chip technology are applied to cleaning methods and tools, metal processing machinery parts, and dust removal. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

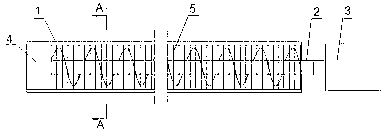

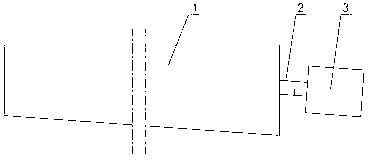

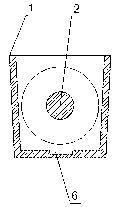

[0031] Such as figure 1 As shown, the chip collection device using the auger mechanism includes a housing 1, an auger shaft 2, a driving motor 3 and a fixed body 4, and the housing 1 is arranged on both sides of the milling machine platform. Such as image 3 As shown, the radial section of the housing 1 is U-shaped. Both ends of the casing 1 are open, the fixed body 4 is arranged at one end of the casing 1, the auger shaft 2 is arranged in the casing 1, one end of the auger shaft 2 is fixed on the fixed body 4 in rotation, the other end of the auger shaft 2 One end protrudes from the end of the housing 1 without the fixed body 4 and is connected to the output shaft of the driving motor 3 , there is a gap between the driving motor 3 and the housing 1 .

[0032] The driving motor 3 drives the auger shaft 2 to rotate, thereby taking away the cutting chips falling in the housing 1 , and the cutting chips fall out from the gap between the housing 1 and the driving motor 3 . This...

Embodiment 2

[0034] Such as image 3 As shown, in this embodiment, on the basis of the above-mentioned embodiments, the two sides of the housing 1 are inclined outwards, so that the housing 1 has a structure that is wide at the top and narrow at the bottom, which is more conducive to cutting chips entering the housing 1. Prevent cutting chips from accumulating on the edge of the housing 1.

Embodiment 3

[0036] Such as figure 1 As shown, this embodiment further includes a fence 5 on the basis of the above embodiments, and the fence 5 is arranged on the top of the housing 1 . The fence 5 can prevent workers from stepping into the housing 1 by mistake, which improves the safety of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com