Bean curd dicer

A dicing machine, tofu technology, applied in metal processing, etc., can solve the problems of slow processing speed, poor work fluency, tofu block damage, etc., and achieve the effect of small overall size, convenient operation, and easy action process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

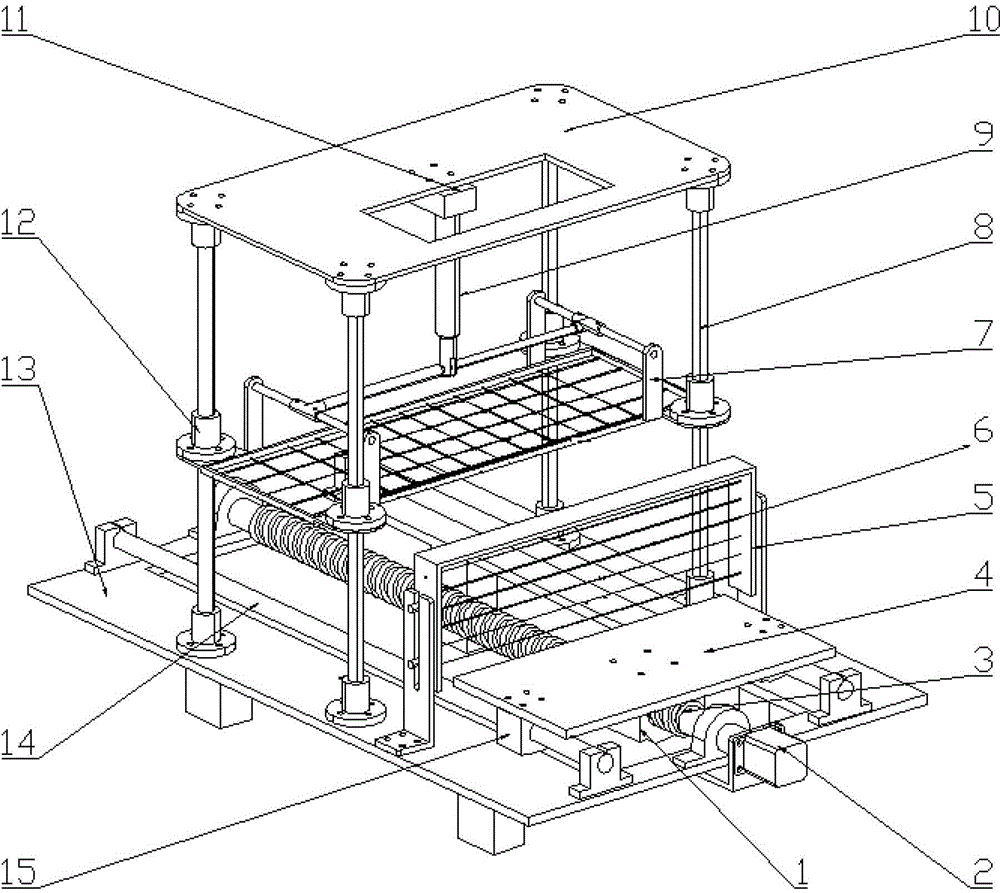

[0014] Below, combined with figure 1 The present invention is described in further detail. The present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following examples.

[0015] Please refer to figure 1 , the present invention proposes a tofu cutting machine, comprising: a base 13; a horizontal guide rail 14, fixed on the base 13, and the horizontal guide rail 14 includes a pair of guide rails parallel to each other; a tray 4, used for placing tofu, supported on the base On the horizontal guide rail 14, and can slide along the horizontal guide rail 14, under the tray 4 are provided with a screw 3 driven by the motor 2 and a nut 1 that transmits the movement of the screw 3 to the tray 4, the nut 1 It is fixed on the lower part of the tray, wherein the horizontal guide rail 14 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com