Quick-change type driving mechanism of paper indentation and trimming device

A driving mechanism, quick-change technology, applied in the direction of machining/deformation, etc., can solve the problems of paper deformation, error, positioning error, etc., and achieve the effect of balanced feeding pressure and suitable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

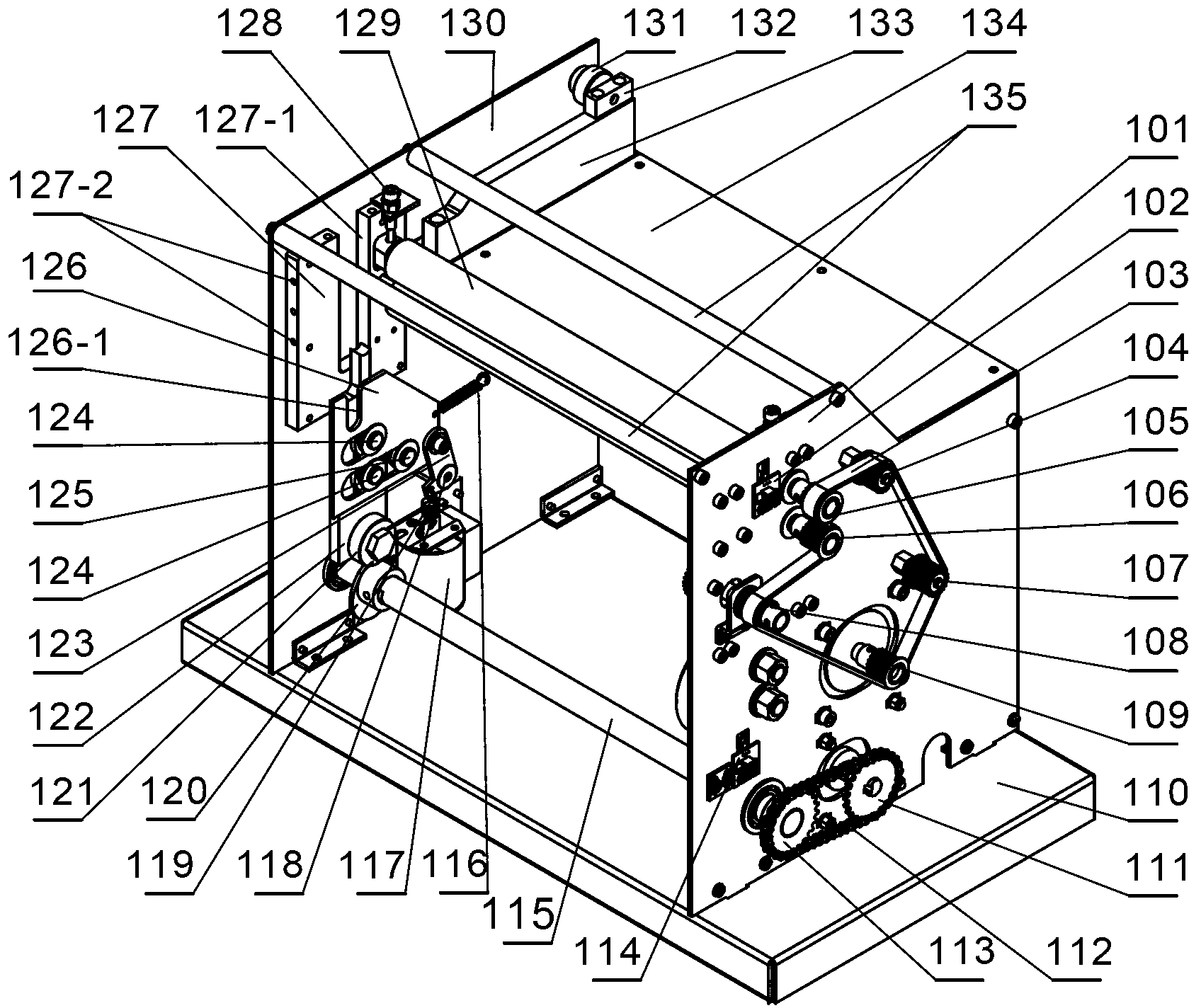

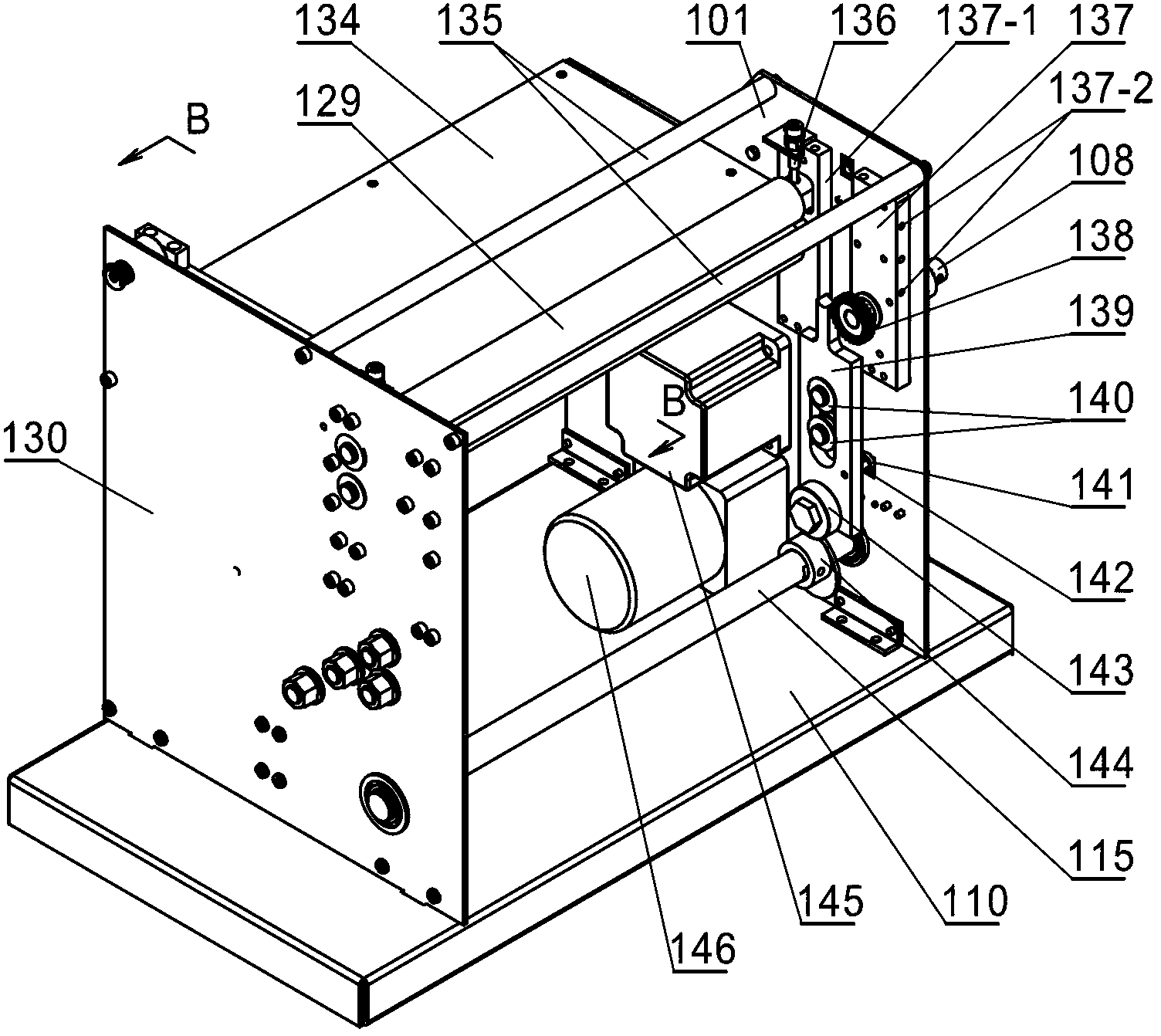

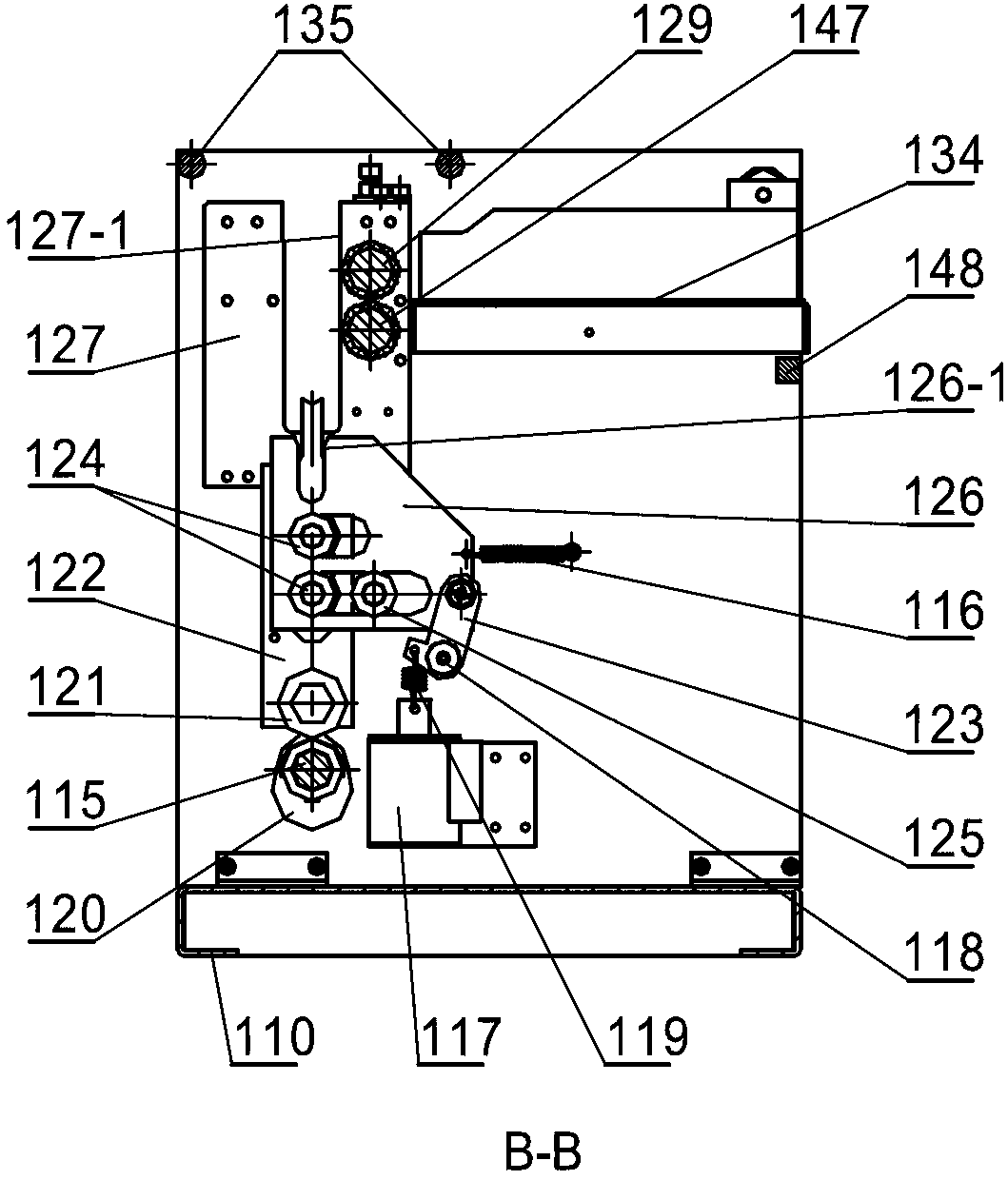

[0019] A driving mechanism for a quick-change paper creasing and cutting device, which is provided with a base 110, a front wall panel 101, a rear wall panel 130, two support rods 135 straddling the upper parts of the front and rear wall panels, and the front and rear wall panels The main body frame formed by the fixed square bar 148 that the right part straddles, the front fixed plate 137 is fixedly installed on the inner surface of the front wall panel, and the rear fixed plate 127 is fixedly installed on the corresponding rear wall panel inner surface top, and the front and rear fixed plates are opened. There are vertical U-shaped card slots 137-1 and 127-1 (for quick insertion and removal of other functional parts), and connecting screw holes 137-2 and 127-2 are provided on the outside of the front and rear fixing plates (for quick Installation and removal of other functional parts), the middle part of the inner surface of the front wall panel is installed with two front to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com