Dyeing device for clothes

A technology for dyeing equipment and clothing, which is applied in the field of dyeing equipment, and can solve problems such as uneven heating, small heating area of dye liquor, and large temperature difference of dye liquor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

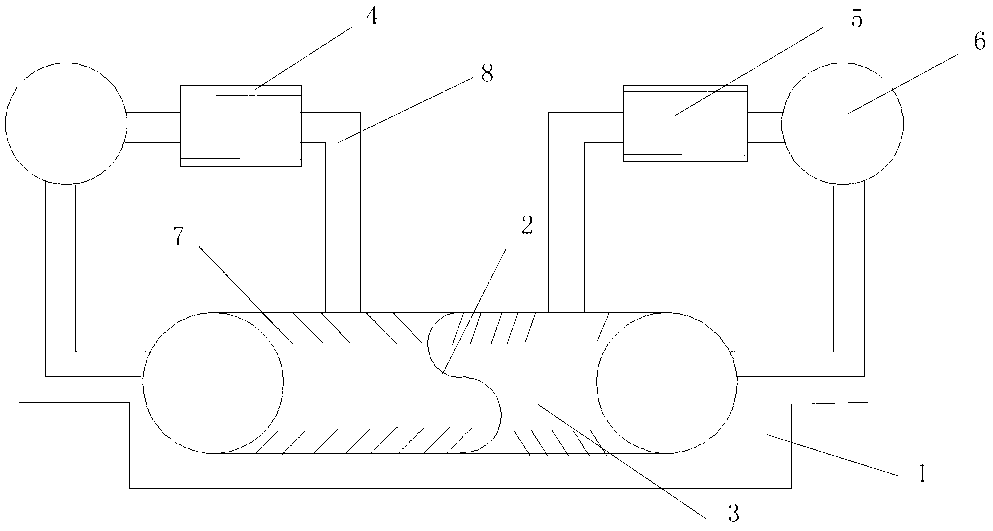

[0015] Such as figure 1 As shown, a garment dyeing equipment includes: a constant temperature oscillator 1, a partition plate 2, a drum 3, two heat exchangers 4, two dyeing solution tanks 5, two pumps 6 and a conduit 8. Wherein the drum 3 is also provided with an agitator 7 on the inner wall, and the drum 3 is connected with the power system. The dye solution tank 5 is respectively connected to the pump 6 and the drum 3 through a conduit 8, and the other end of the pump 6 is connected to the drum 3 through a conduit 8. A heat exchanger 4 is arranged around the dye solution tank 5, and the dye solution flows in through the conduit 8 Drum 3, and under the action of pump 6, return to the dye solution tank. The partition plate 2 is located inside the drum 3 and divides the inner space of the drum 3 . The drum 3 is immersed in the constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com