Method for achieving prestressed cylindrical cable bar latticed shell structure forming by aid of length-adjustable press rod

A cylindrical reticulated shell structure and prestressing technology, applied in building construction, building material processing, construction, etc., can solve the special structure, forming process and construction technical measures of self-balancing prestressed cable-rod cylindrical reticulated shell structure It is unclear and hinders the application and development of new structural systems, so as to avoid implementation difficulties, good application prospects, and save engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

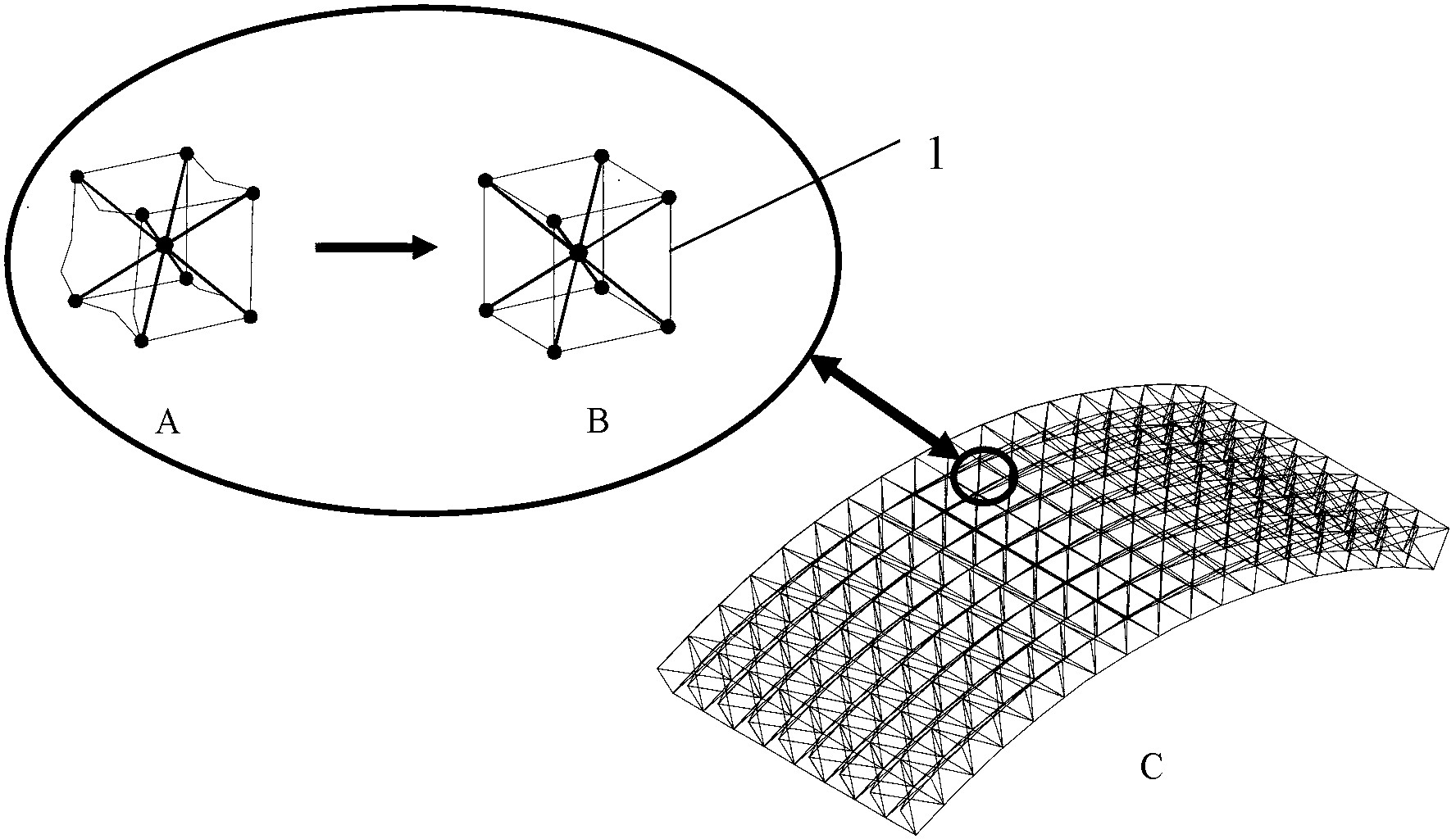

[0039] Specific implementation mode one: as Figure 1 to Figure 5 , the method for realizing the forming of the prestressed cylindrical cable-strut reticulated shell structure with the length-adjustable compression rod described in this embodiment is realized according to the following steps:

[0040] Step 1. Calculate the net blanking length of each cable:

[0041] The calculation formula for the blanking length of any cable i in the reticulated shell structure is:

[0042] l in formula (1) 0i Indicates the net blanking length of any cable i in the cylindrical reticulated shell structure, and the net blanking length is the length of the cable between the outer edges of the two spherical nodes connected to the cable after the cable is installed; l di Indicates the net design length of any cable i in the cylindrical reticulated shell structure, and the net design length refers to the length of the cable between the outer edges of two spherical nodes connecting the cables de...

specific Embodiment approach 2

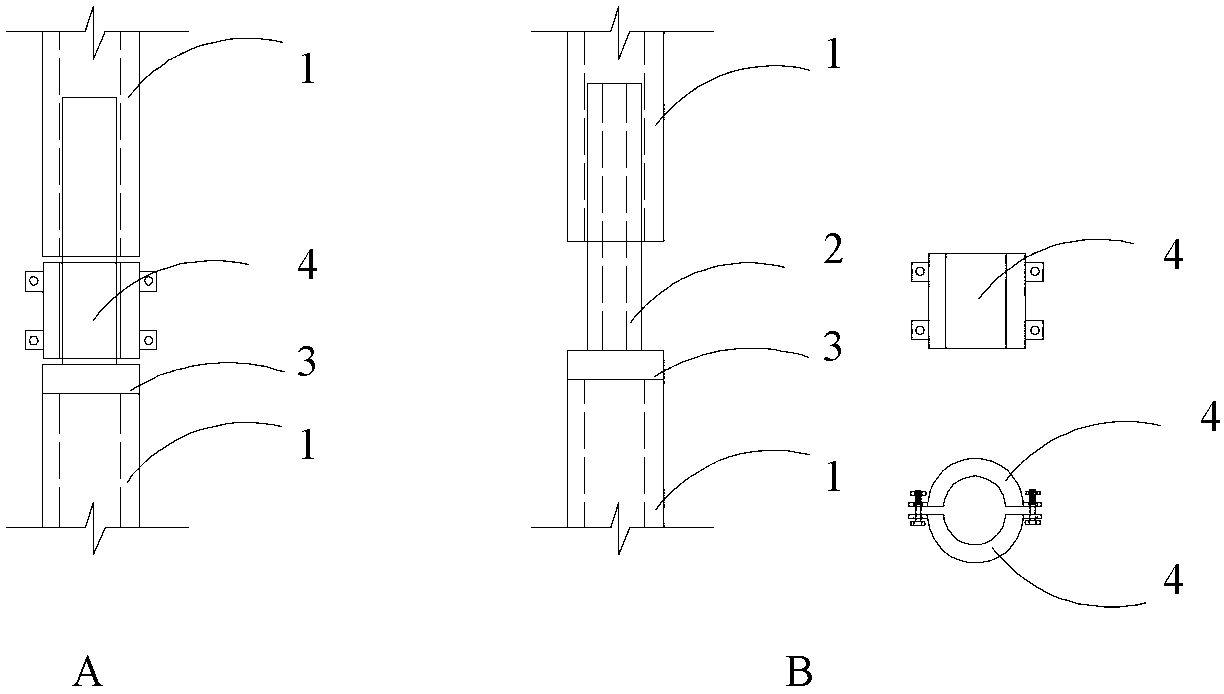

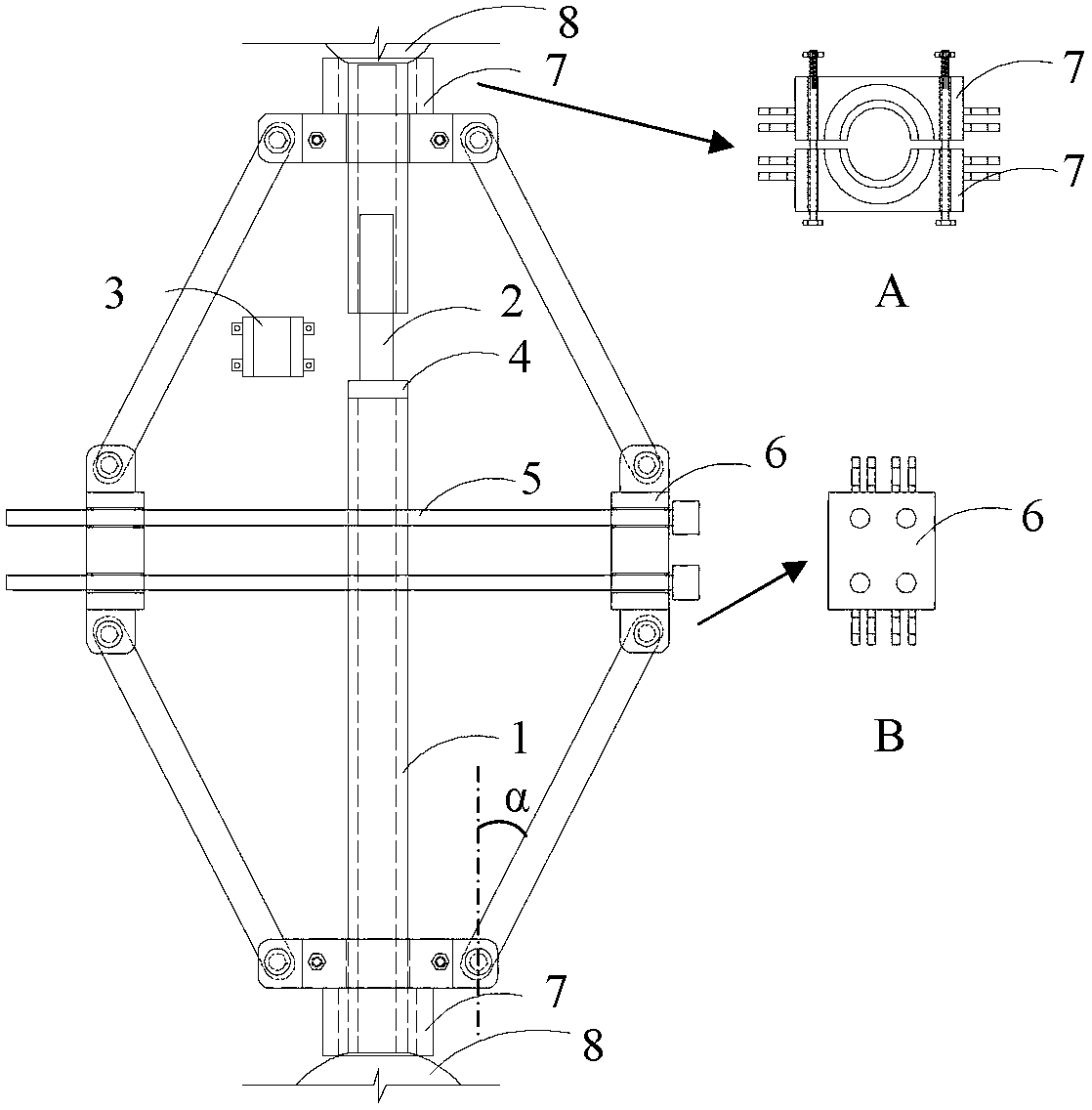

[0055] Embodiment 2: In step 3, during the elongation operation of the compression bar, the jacking device is installed on the compression bar to be extended, and the angle α of the support bar is reduced by stretching the screw rod through the push-type jack, and the compression bar is lifted. push long. Fix the backing tube 4 on the connecting rod 2, remove the jacking device after the backing tube and the pressing bar are temporarily or permanently fixed. Other implementations are the same as the first implementation.

specific Embodiment approach 3

[0056] Specific implementation method three: in step three to determine the bar elongation scheme, according to the operation sequence between the operating units, it should start from the structural basic unit at the center of the top of the reticulated shell structure, and then proceed to the boundary direction of the reticulated shell structure in batches carried out successively. The principle of selecting two or four structural basic units adjacent to the formed structural unit as a batch of forming operations, for Figure 5 For the reticulated shell shown, according to the above principles, the operation sequence among the various operation units is ①→②→③→④→⑤→⑥→⑦→⑧, and the rod elongation operations of the operation units of the same batch must be completed simultaneously. Carry out steps 4 and 5 according to this principle. Other implementations are the same as the first implementation.

[0057] Experimental verification of the effectiveness of the inventive method

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com