Tube well overhanging protection structure and brickwork tube well in-situ protection construction method

A technology for protecting structures and construction methods, applied in infrastructure engineering, protection devices, underwater structures, etc., can solve the problem of large consumption of time, space, manpower and material resources, loss of function of masonry tube wells, and masonry cracking of masonry tube wells and other problems, to achieve the effect of avoiding demolition and relocation, shortening construction time and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

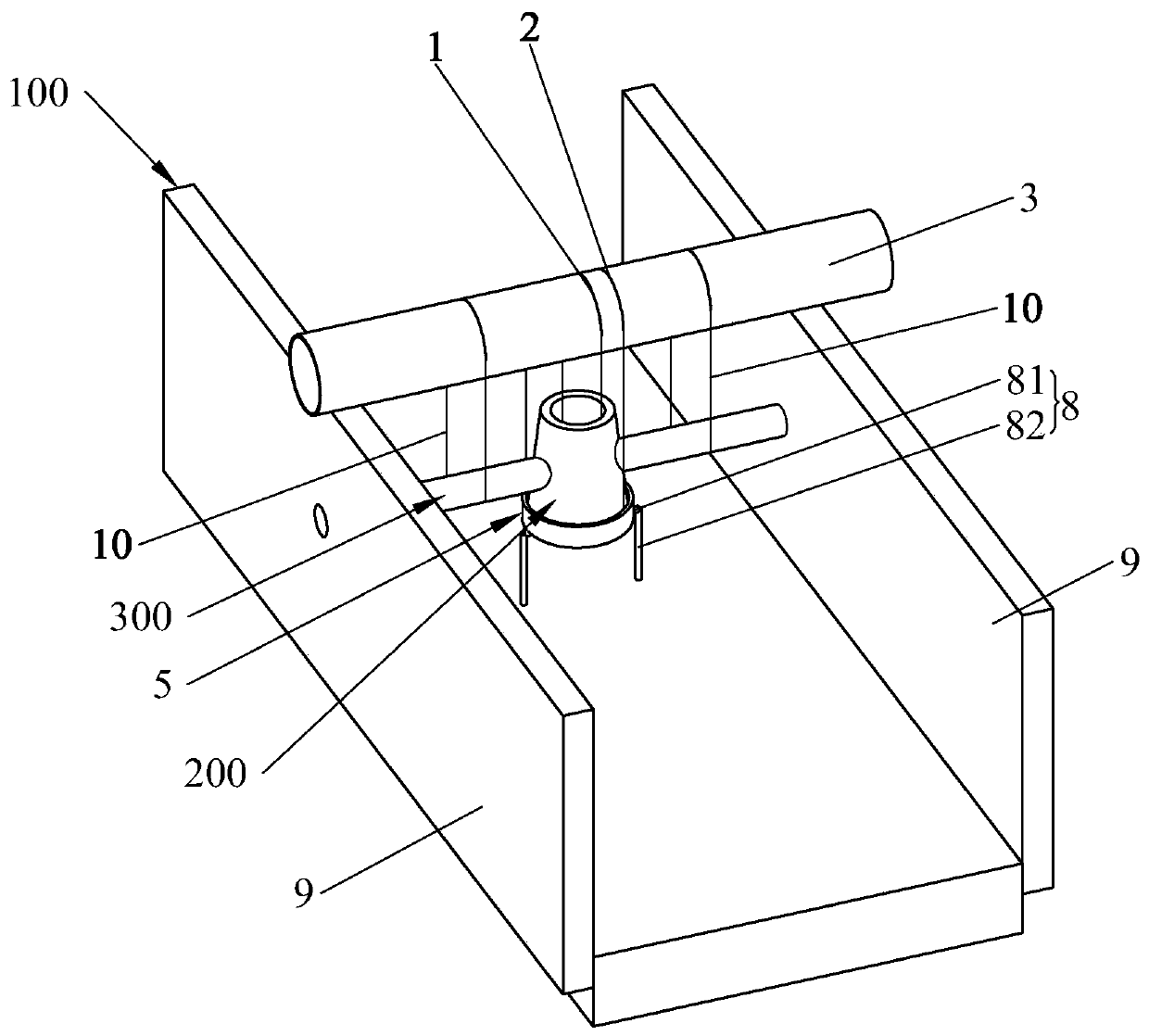

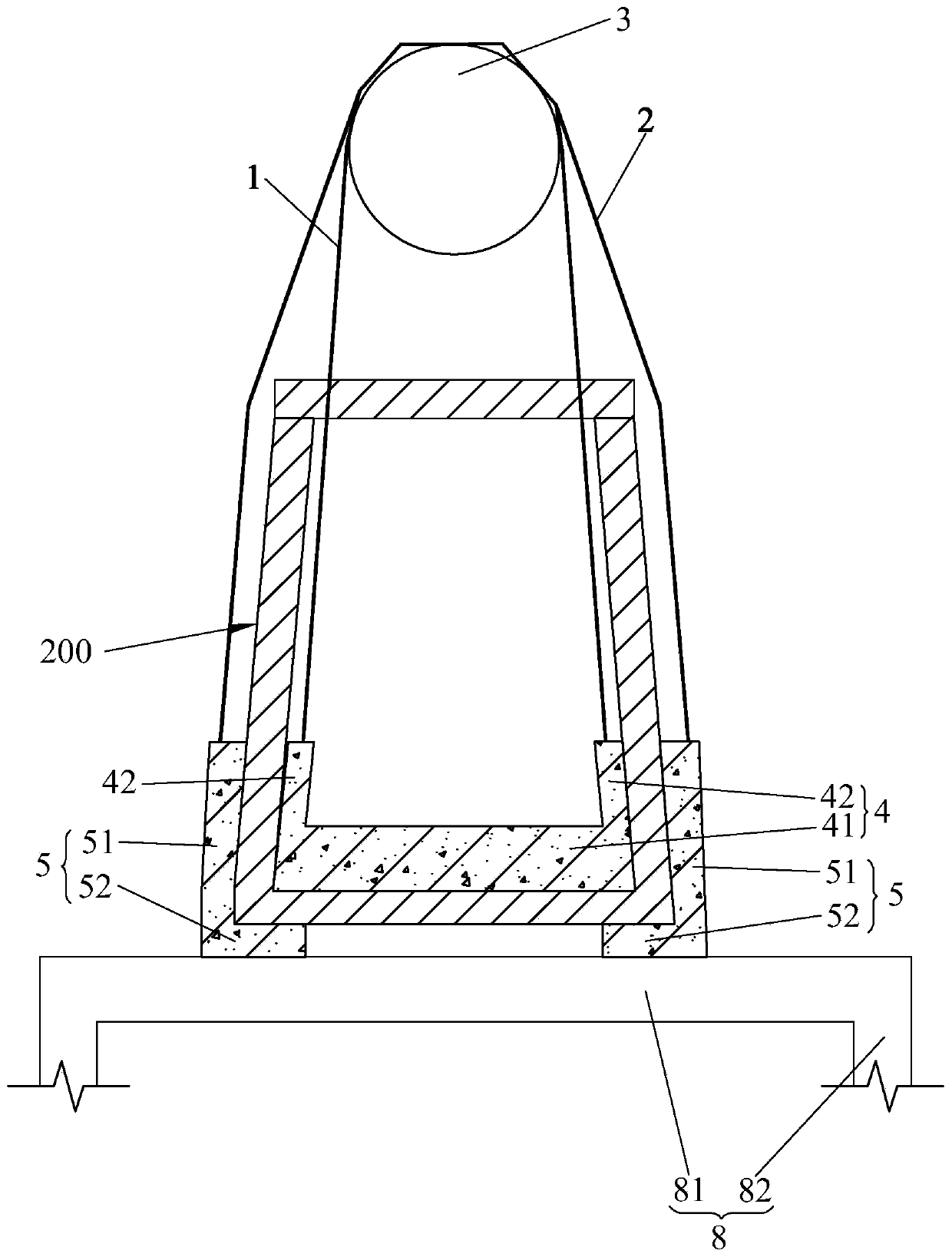

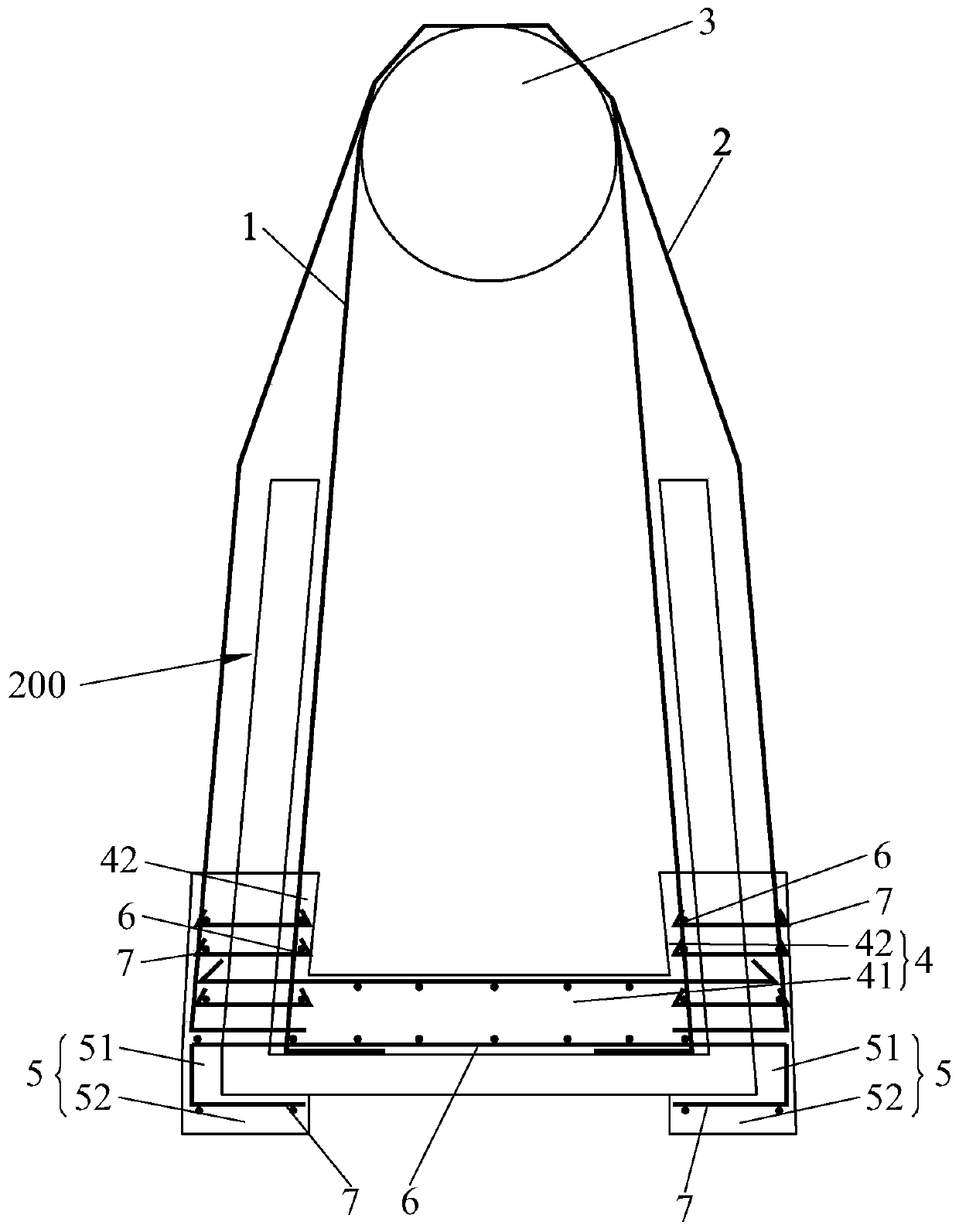

[0026] see Figure 1 to Figure 3, the tube well suspension protection structure 100 of the present invention is used to protect the masonry tube well 200, which includes an inner hanging plate traction member 1, an outer hanging plate traction member 2, a load-bearing beam 3, an inner hanging plate reinforcing bar 6, an outer hanging plate reinforcing bar 7, The inner hanging plate 4 for connecting with the inner side wall of the tube well 200, the outer hanging plate 5 for connecting with the outer side wall of the tube well 200, the connecting pipe drawing member 10 for fixing the connecting pipe 300 of the tube well 200, The supporting beam column 8 and at least two load-bearing side walls 9 that carry the outer suspension plate 5 are symmetrically arranged, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com