Micro-positive pressure auto-compensation rock bit lubricating system

A technology of automatic compensation and roller cone bits, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve problems such as grease surplus, bearing wear, and roller cone shedding, so as to improve lubrication performance, increase service life, and ensure lubrication effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

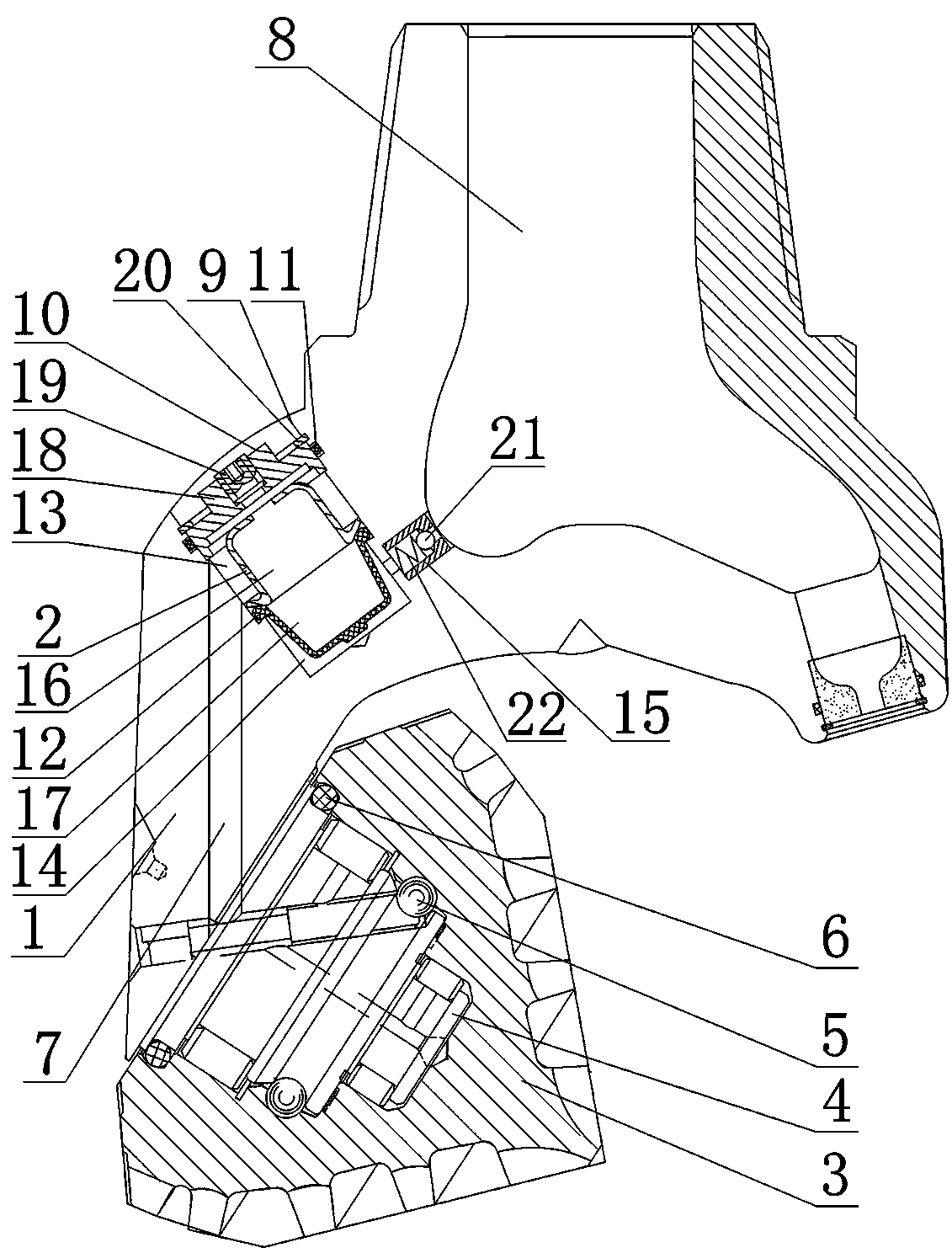

[0029] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0030] Such as figure 1As shown, the roller cone bit lubrication system with micro positive pressure automatic compensation includes claw 1 and cone 3, claw 1 is provided with journal 4, cone 3 is installed on journal 4 through bearing 5, and cone 3 A sealing ring A6 is provided between the inner hole port and the journal 4 to form a bearing chamber, the claw 1 is provided with an oil passage 7 connected to the bearing chamber, the claw 1 is provided with a mud passage 8, and the lower part of the claw 1 is provided with The nozzle connected to the mud passage 8, the upper part of the claw 1 is provided with an oil storage bag hole 9, and an oil storage bag 10 is arranged in the oil storage bag hole 9, and the end of the oil storage bag 10 close to the port of the oil storage bag hole 9 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com