Shockproof bush

A bushing and main body technology, which is applied in the field of shock-proof bushings, can solve the problems of unsatisfactory shock-absorbing and shock-absorbing effects, and achieve the effects of good shock-absorbing effect, increased deformation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

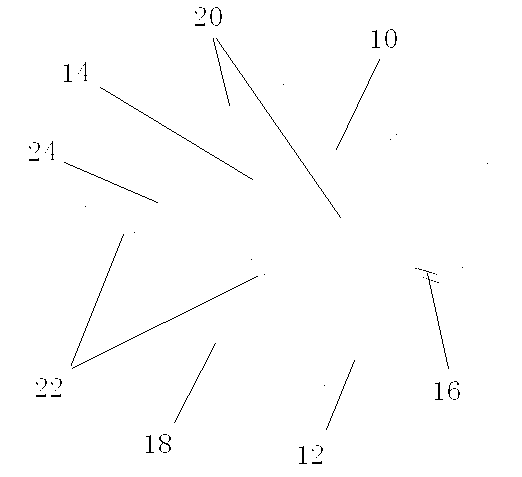

[0016] Such as figure 1 As shown, a shockproof bushing of the present invention includes a block-shaped main body 10 . The main body 10 includes a bottom surface 12 and a front surface 14 opposite to each other, wherein the bottom surface 12 of the main body 10 is provided with a first groove 16 , and the first groove 16 runs through the plane of the bottom surface 12 . The bottom surface 12 of the main body 10 is further provided with a second groove 18 perpendicular to the first groove 16 , and the second groove 18 runs through along the plane of the bottom surface 12 . The cross section of the first groove 16 is semicircular, which has the best shock absorption effect, and the cross section of the second groove 18 is square.

[0017] The front 14 of the main body 10 is provided with two clamping parts 20 protruding from the front 14 of the main body 10 and parallel to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com