Debugging device applied to pairing of negative control terminal and ammeter

A technology of negative control terminals and electric meters, which is applied in the field of paired debugging devices between negative control terminals and electric meters, which can solve problems such as power consumption, debugging danger, and metering circuit wiring errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

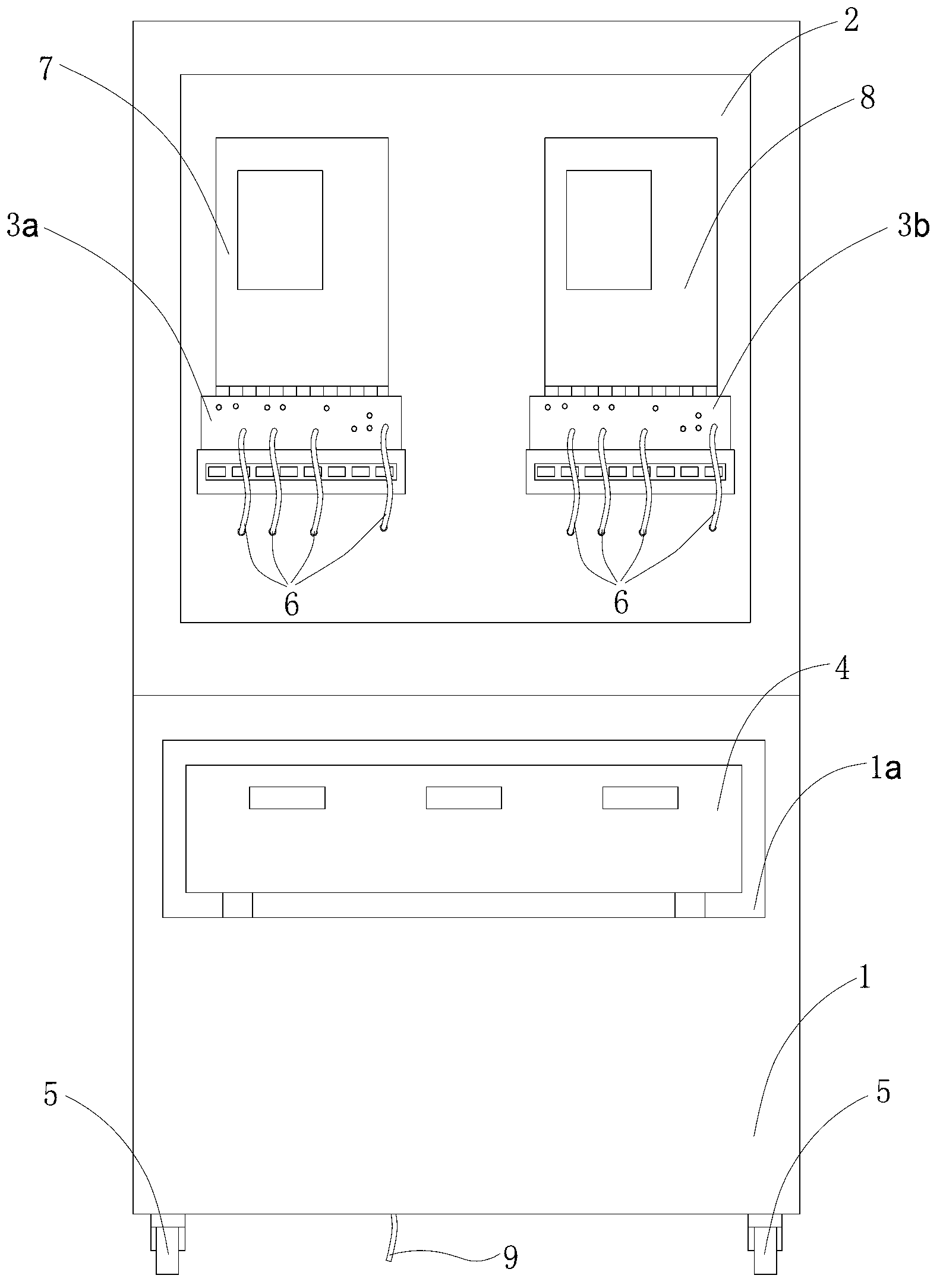

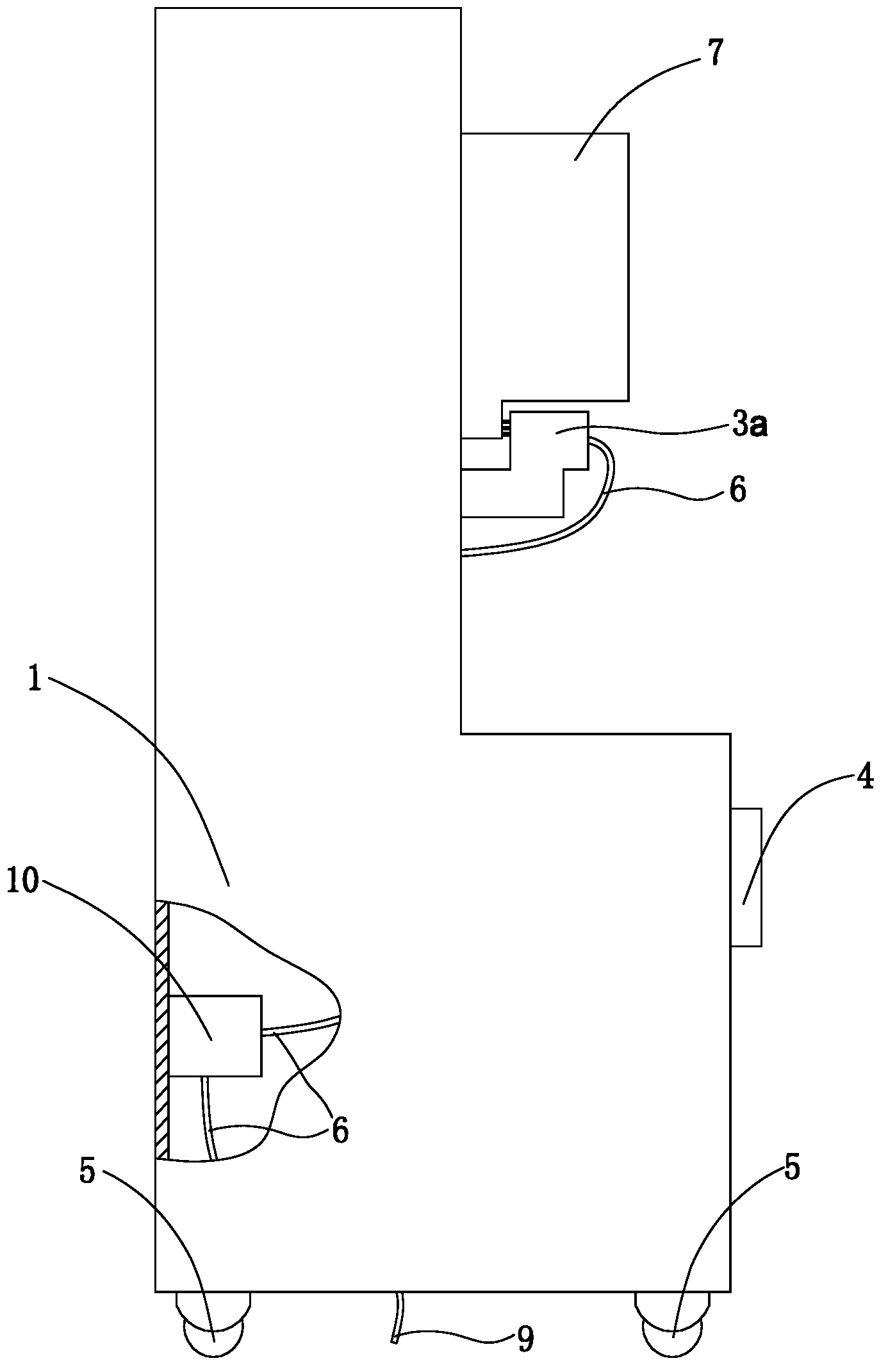

[0017] Such as Figures 1 to 2 As shown, the cabinet bracket 1 of this device is made of stainless steel, and the upper surface of the bracket 1 has a mounting plate 2 made of epoxy resin, and the two connecting brackets fixed by bolts in the middle of the mounting plate 2 are the first connecting bracket 3a and the second meter connection frame 3b.

[0018] There is a groove 1a in the middle of the bracket 1, and an electric meter calibrator 4 is placed in the groove 1a, and a leakage protector 10 is also installed in the bracket 1.

[0019] The first meter connection frame 3a and the second meter connection frame 3b are connected by wire 6 to realize the voltage parallel connection between the first meter connection frame 3a and the second meter connection frame 3b, and the first meter connection frame 3a and the electric meter calibrator 4 are connected by wire 6 to realize current series connection and voltage parallel connection between the electric meter calibrator 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com