Heavy oil supercritical extraction multistage parallel separation treatment system and treatment method

A separation treatment and supercritical technology, which is applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of maximum processing capacity limitation, inability to produce at the same time, different specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

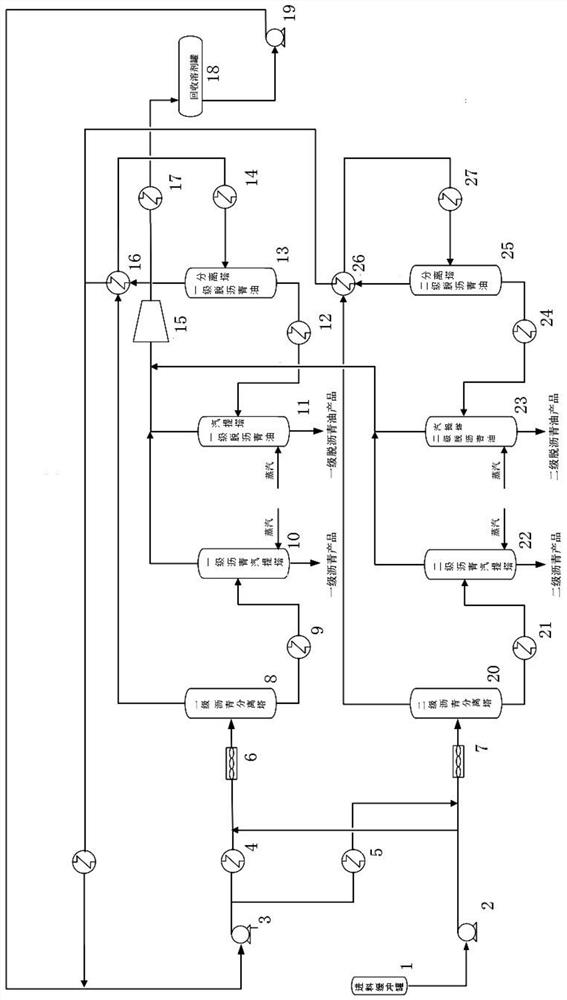

[0036]A heavy oil supercritical extraction multistage parallel separation treatment system, which includes:

[0037] Feed unit: including feed buffer tank 1 and feed pump 2;

[0038] Solvent mixing unit: including solvent pump 3, primary solvent cooler 4, secondary solvent cooler 5, primary mixer 6, and secondary mixer 7. The solvent pump passes through the primary solvent cooler and secondary solvent cooler respectively After merging with the first-stage feed pipeline and the second-stage feed pipeline of the feed pump, it enters the first-stage mixer and the second-stage mixer respectively;

[0039] N-level supercritical extraction separation unit: including N groups of supercritical extraction separation units arranged in parallel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com