Micro-channel fluid photo-grey glasses

A technology of color-changing glasses and micro-channels, applied in the field of color-changing glasses, can solve the problems of slow color changing speed and single color changing, and achieve the effect of strong controllability and easy personalized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

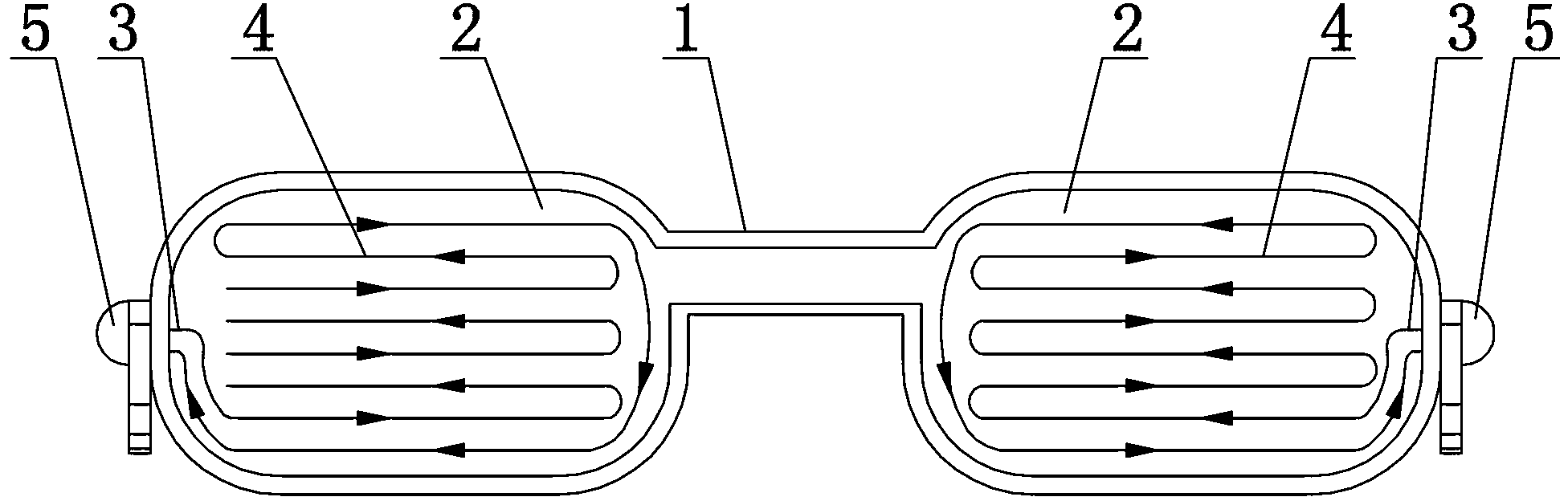

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises picture frame 1, lens 2, connecting flow channel 3, discoloration flow channel 4 and actuator 5, lens 2 is arranged in picture frame 1, left lens and right lens are respectively provided with color change flow channel 4 , the actuator 5 is installed on the frame 1, the connecting channel 3 is arranged on the frame 1 between the discoloration channel 4 and the actuator 5, the connection channel 3 communicates with the discoloration channel 4, the cavity of the actuator 5 is connected to the The flow channel 3 is connected, and the cavity of the actuator 5 is filled with colored fluid. Under the action of the actuator 5, the fluid can enter the color-changing flow channel 4 on the lens through the cavity of the actuator 5 through the connecting channel 3, or return to the actuator 5 through manual or automatic control. When the fluid enters the color-changing flow chann...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To describe this embodiment, the colored fluid in the cavity of the actuator 5 in this embodiment is a colored liquid or a colored gas. Such as water, oil, gas or chemical liquids. Other connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

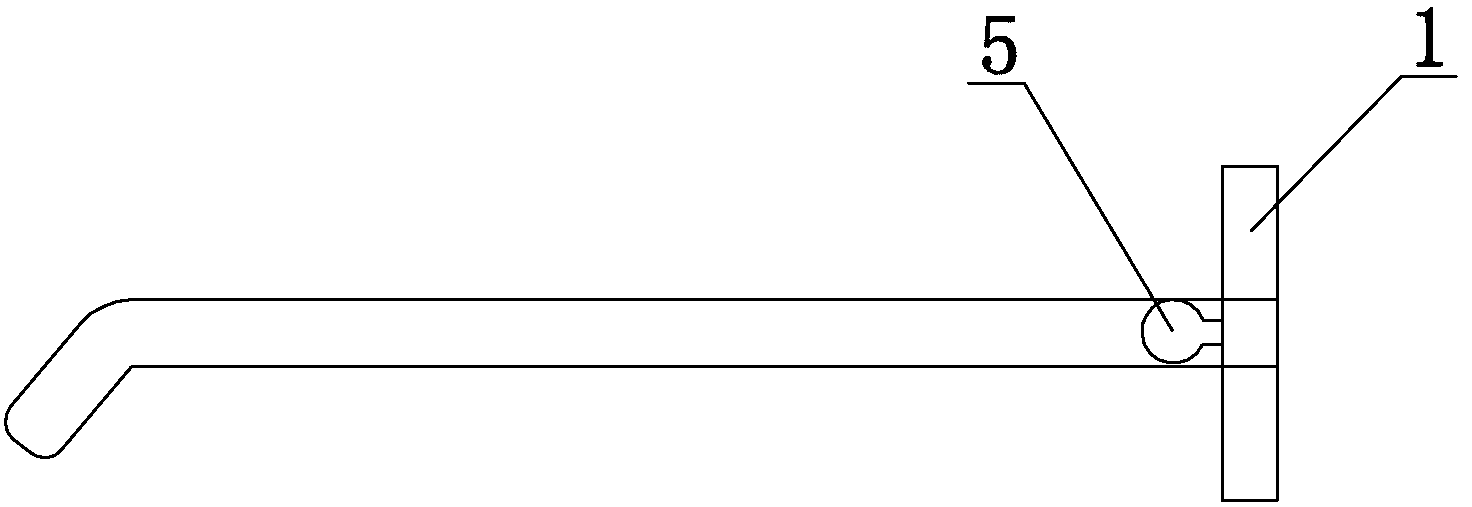

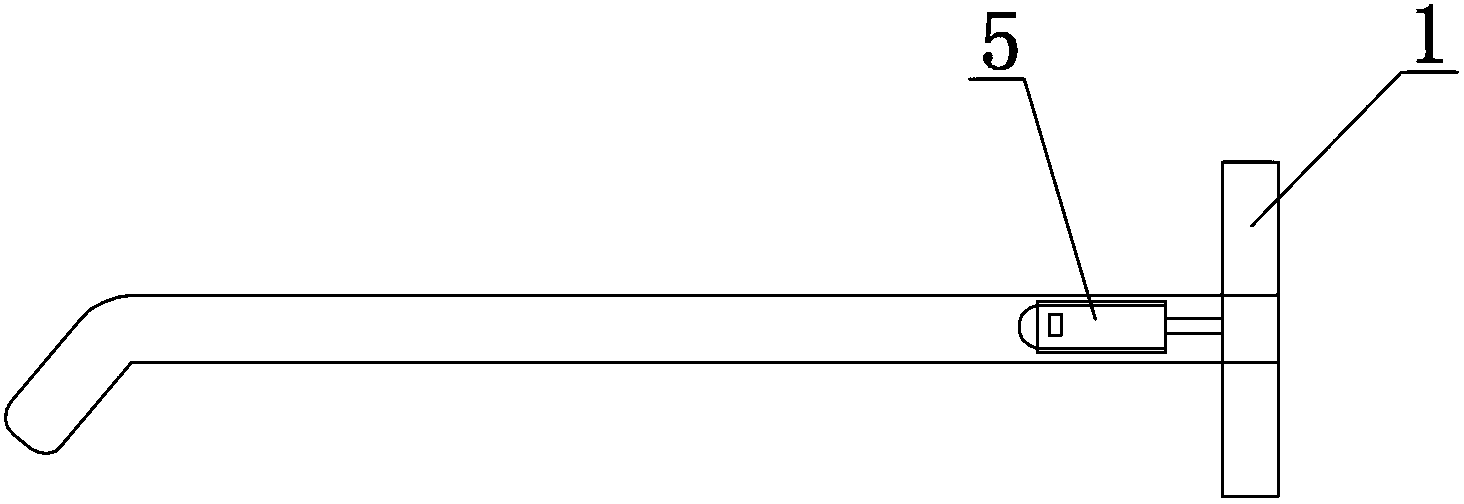

[0010] Specific implementation mode three: combination figure 1 and figure 2 The present embodiment will be described, and the actuator 5 of the present embodiment is a push diaphragm type. Press diaphragm type is prior art. When the diaphragm is pressed, the fluid in the diaphragm cavity is pushed into the color-changing flow channel 4 and the connecting flow channel 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com