Hollow medical needle, and method for producing hollow medical needle

A medical, hollow technology, applied in the direction of manufacturing tools, needles, and instruments introduced into the body, can solve the problems of puncture pain, high puncture resistance, and increased puncture resistance, and achieve the effect of pain relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

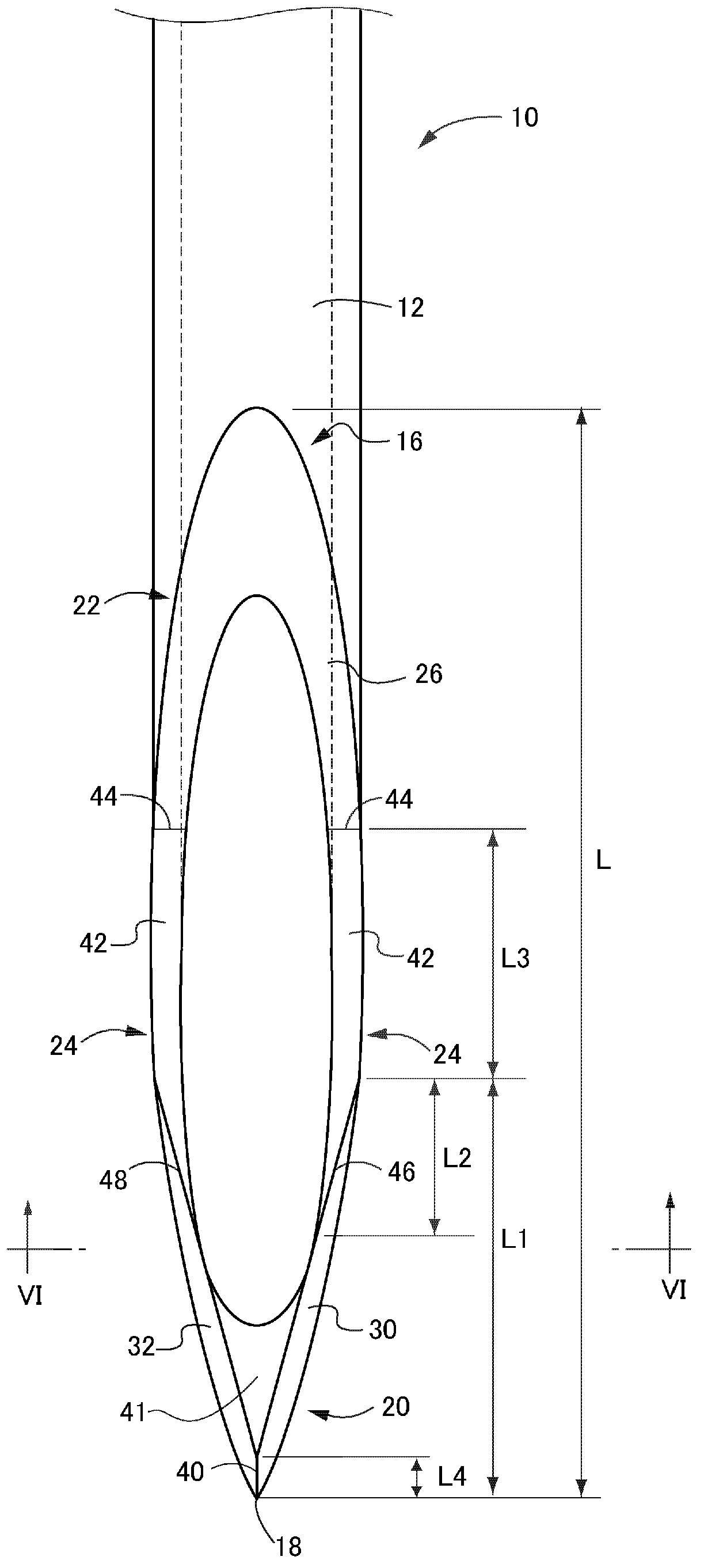

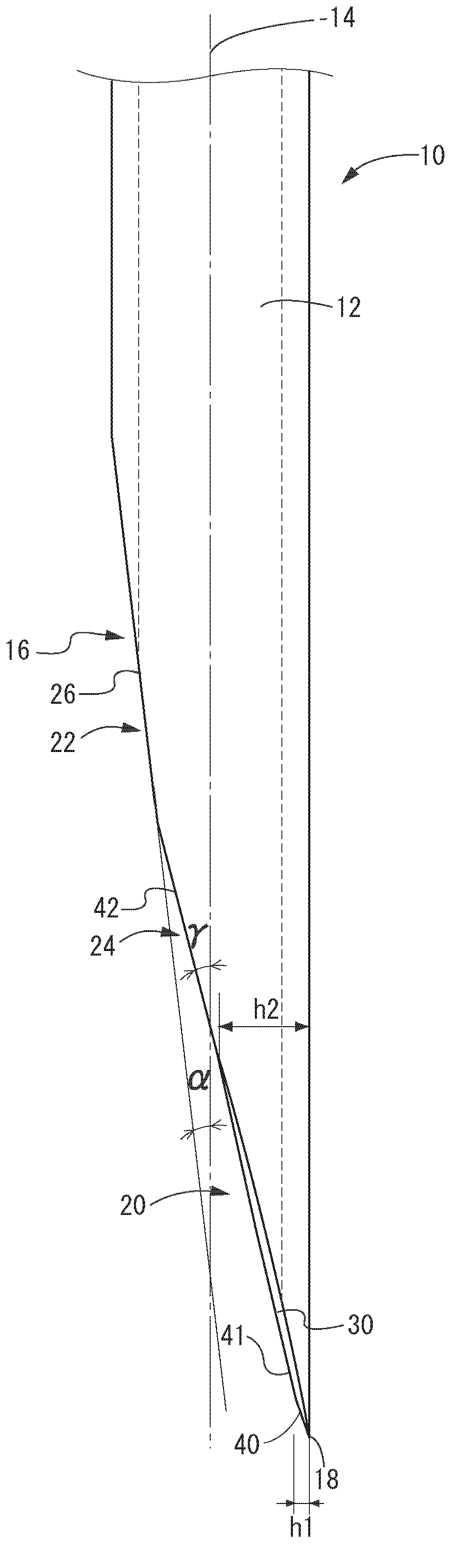

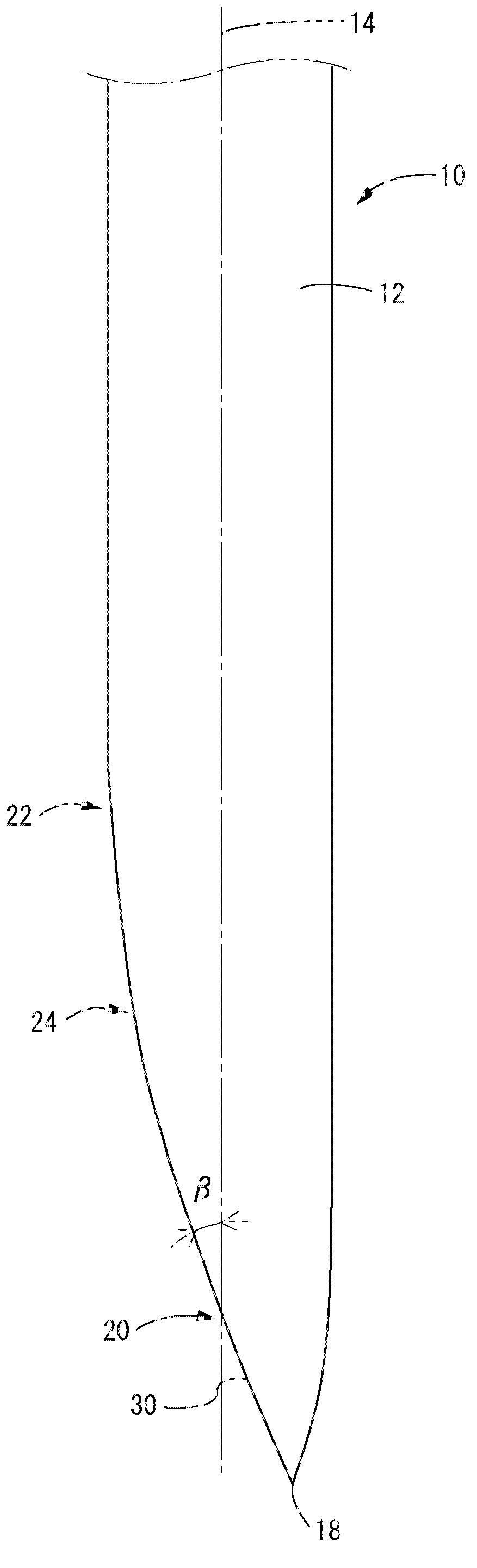

[0076] Figure 9 shown as an example with the above Figure 1 to Figure 6 The measurement results of the puncture resistance of medical hollow needles with the structures shown in and the specific structures shown in [Table 1] and [Table 2] below. This measurement is obtained by directing the central axis of a medical hollow needle towards the surface of a 0.04 mm polyurethane sheet and measuring the resistance value (gf) as the needle advances at a constant speed of 20 mm / min to puncture and penetrate into the sheet. These measurement results show that the hollow needle for medical use constructed according to the present invention suppresses the peak value of the puncture resistance in each puncture of the distal end portion 20, the middle portion 24, and the base end portion 22 at a low level without making it rise, and the peak value The difference between levels is kept small. In [Table 2], h2 indicates the height of the second and third ridges (see figure 2 ).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com