Assembling structure of fast-heating electric water heating device

A technology of boiling water device and assembly structure, which is applied in the field of assembly structure of fast-heating electric heating water boiling device, can solve the problems of high manufacturing cost, large size, slow water outlet speed, etc., and achieve simple and easy processing technology, compact structure, The effect of less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

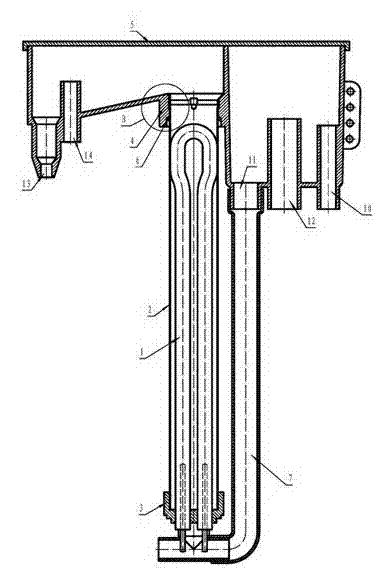

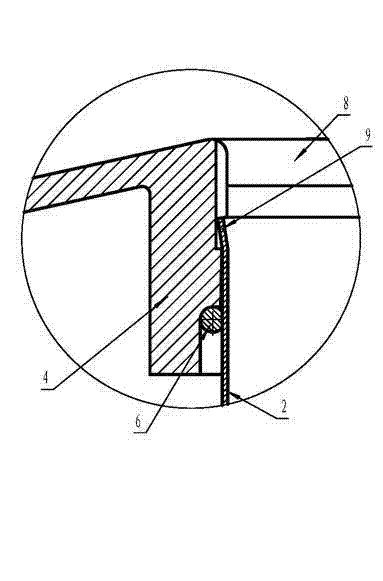

[0015] as attached Figure 1-4 Schematically, the device of the present invention is mainly composed of electric heating tube 1, heating cylinder 2, flange 3, water inlet and outlet chamber 4, upper cover 5, sealing ring 6 and water inlet pipe 7, as figure 1 As shown, the electric heating tube 1 is installed inside the heating cylinder 2, and the upper end of the electric heating tube 1 is closely matched with the inner wall of the heating cylinder 2. One is to fix the electric heating tube, and the other is to enable the thermostat installed on the outer wall of the electric heating tube to Sensing temperature as soon as possible to ensure the effect of empty burning protection.

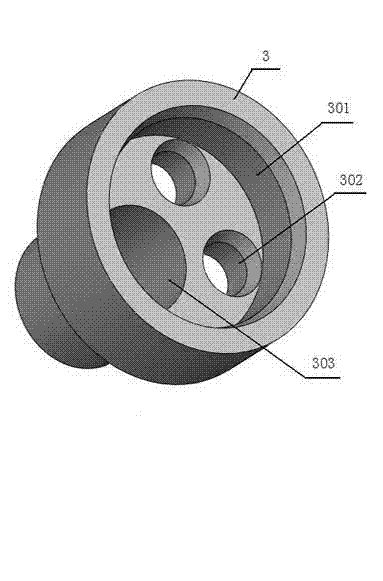

[0016] At the lower end of the heating cylinder 2, the heating cylinder and the electric heating tube are fixed with the flange 3, and connected to the water inlet pipe 7. The flange 3 is made of silicon rubber, and the good elasticity of the silicone rubber is used to make the gap between the flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com