Lid handle

A technology for cover handles and fastening devices, applied in the field of cover handles, can solve problems such as difficult handling and inability for users to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

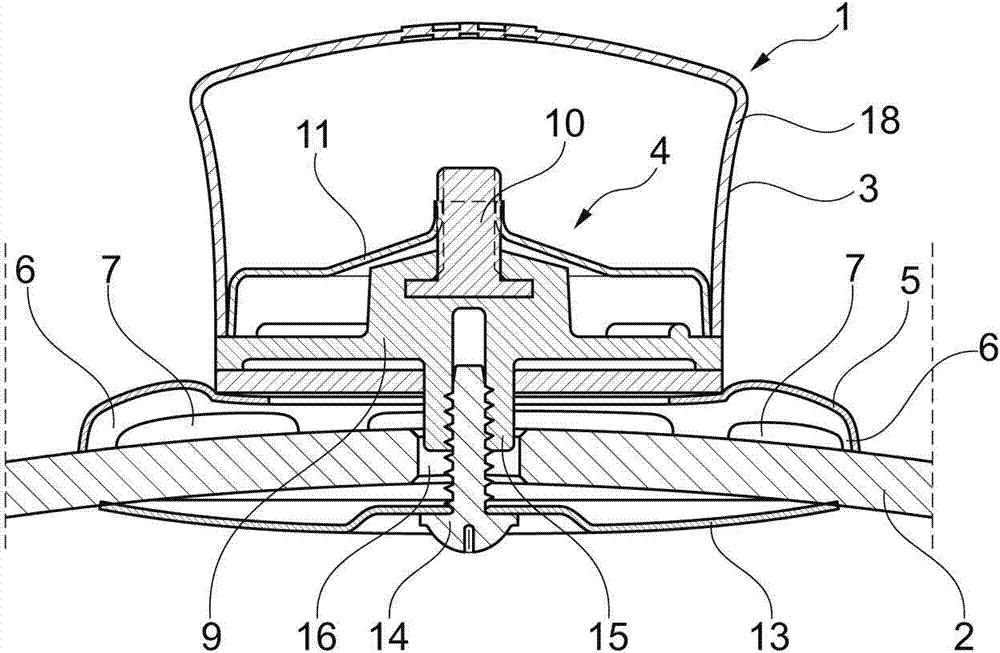

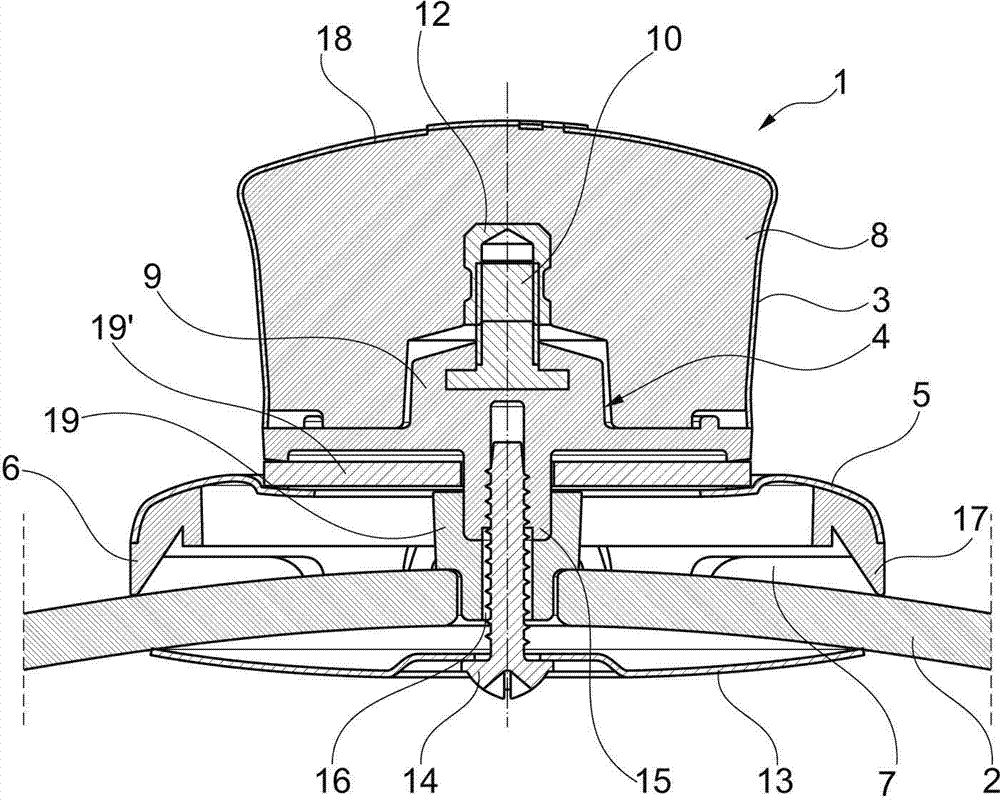

[0018] according to figure 1 and 2 , a lid handle 1 of a cooking vessel (not shown) lid 2 according to the invention comprises a metal surface 3 , for example stainless steel, and fastening means 4 for fastening the lid handle to the lid 2 . Due to the metal surface 3, thermal separation of the lid handle 1 from the lid 2, which heats up during cooking, is essential in order to ensure problem-free handling and safe handling of the lid handle 1 throughout the cooking process. Thus, the purpose of thermal separation is not to exceed a predetermined maximum temperature on the metal surface 3, for example 55° C., during the cooking process.

[0019] To solve the problem of pyrolytic separation, there are numerous alternatives, which can realize the invention alone or in any combination with one another.

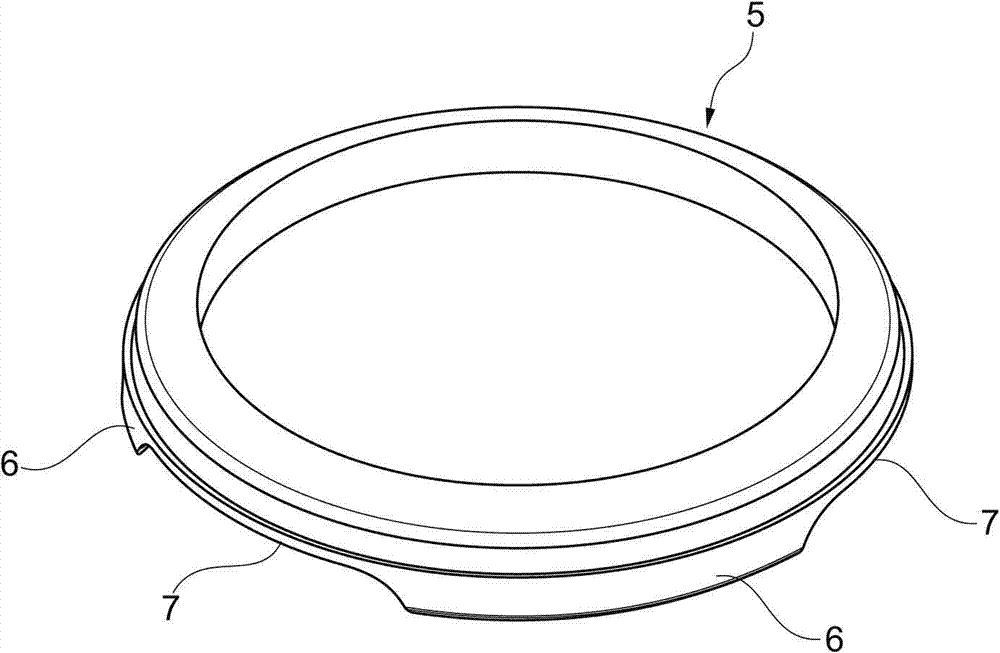

[0020] according to figure 1 and 2 , spacer ring 5, which is also image 3 is shown in the view of , and is supported on the cover 2 by means of feet 6 , which are arranged,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap