Improved plastic film processing apparatus

A technology for plastic film and processing equipment, applied in the field of improved plastic film processing equipment, can solve the problems of high labor consumption, single function, and high worker dependence, and achieve the effects of strong practicability, good safety and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

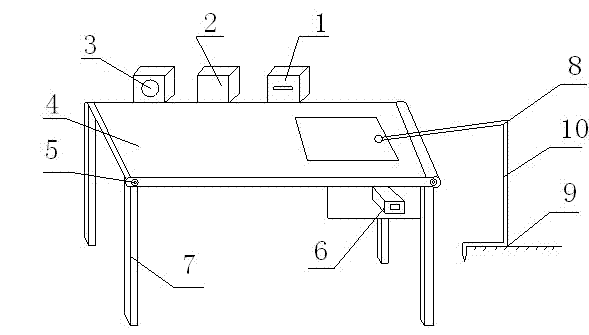

[0013] Such as figure 1 Shown, a kind of improved plastic film processing equipment of the present invention comprises sealing machine 1, heat setting machine 2, compressor 3 and plastic film conveyor belt 4, and plastic film conveyor belt 4 is located at sealing machine 1, heat setting machine 2 and One side of the compressor 3, the two ends of the plastic film conveyor belt 4 are connected to the speed-regulating motor 6 through the roller 5, a support frame 7 is provided under the plastic film conveyor belt 4, and the speed-regulating motor 6 is fixed on the plastic film conveyor belt 4 On the support frame 7 below, the improved plastic film processing equipment also includes a static eliminator 8. The static eliminator 8 includes a base 9 and a static transfer rod 10. The lower end of the static transfer rod 10 is grounded and the upper end is spherical.

[0014] The improved plastic film processing equipment of the present invention is provided with a sealing machine 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com