Self-unlocking spring parallel ejection device

An ejection device and self-unlocking technology, which is applied in the direction of launching/dragging transmission devices, can solve the problems of insufficient ejection force, inability to adjust, complicated control, etc., and achieve the effect of large ejection force, compact device, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

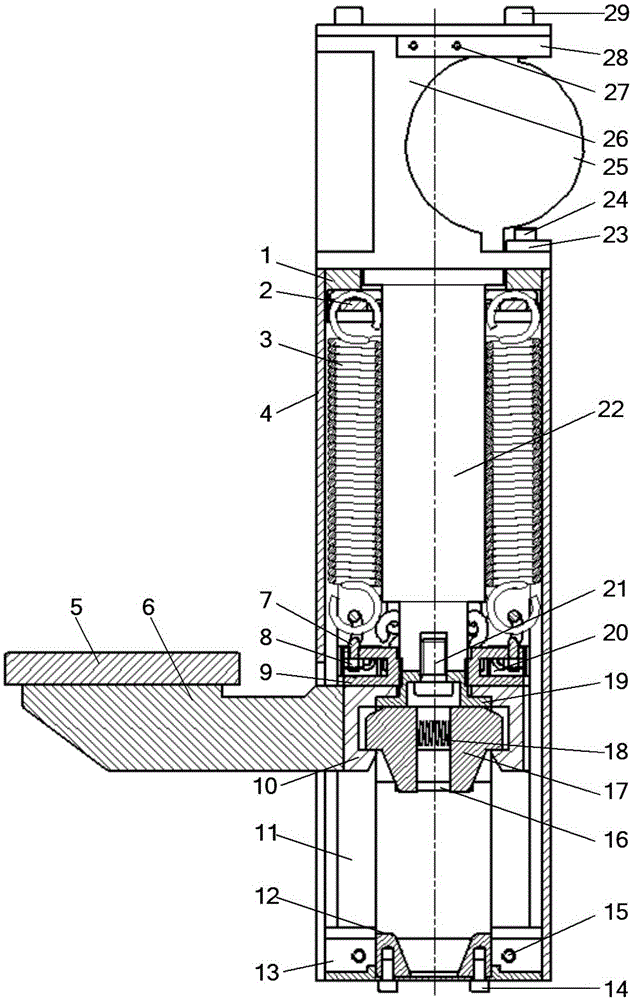

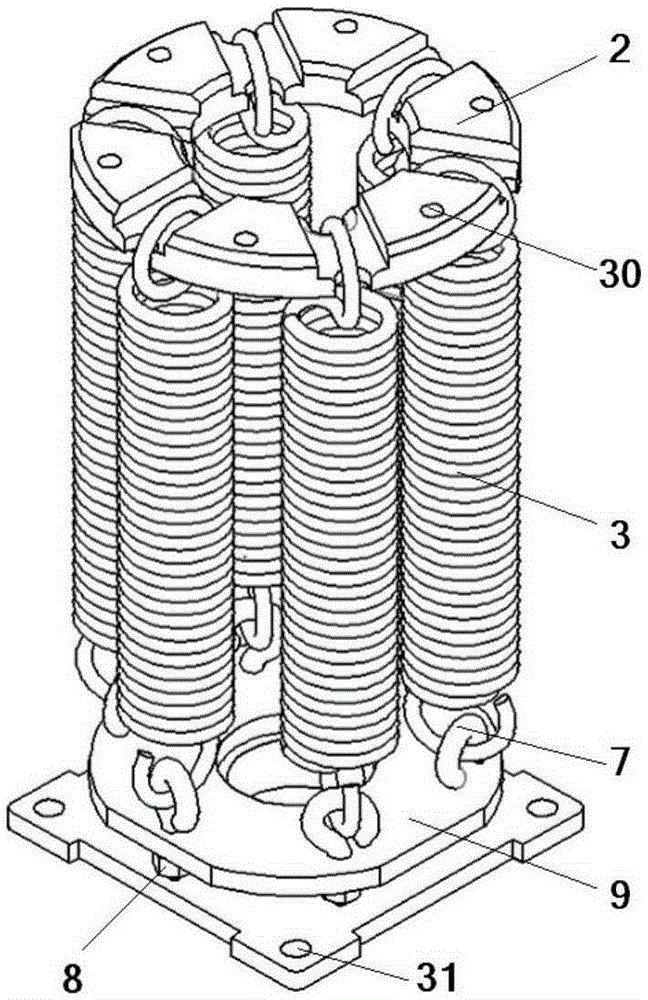

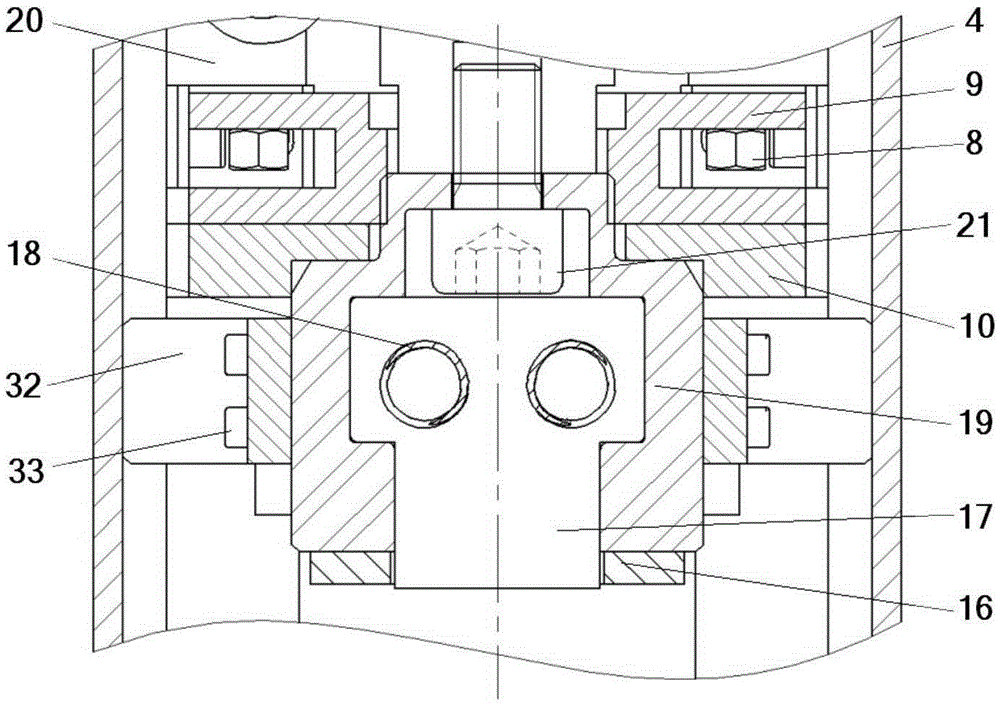

[0021] figure 1 It is the general assembly structure diagram of this embodiment, including the power unit with the linear push rod 22 as the main component, the parallel spring unit with the tension spring 3 as the main part, the ejection operation unit with the locking claw 17 as the main part, and the unlocking block 12 and slide rail 11 are the housing unit of main parts. The upper end of the housing 4 is threadedly connected to the top surface 1, the lower end is fixed to the bottom surface 13 through bolts 15, the ejection limiter 20 is installed on the inner wall of the outer shell 4, and the slide rail 11 is set at the lower end of the ejection limiter 20 on the inner wall of the outer shell 4. Playing the role of ejection guide, the unlocking block 12 is fixedly connected with the bottom surface 13 through bolts 14 .

[0022] refer to figure 1 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com