Unmanned-operation automatic control system for construction hoist (construction elevator)

An automatic control system and construction elevator technology, applied in elevators, transportation and packaging, etc., can solve the problems of increasing construction costs, increasing the danger of operators when working at heights, and inconvenient construction progress, so as to improve construction progress and save wages , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

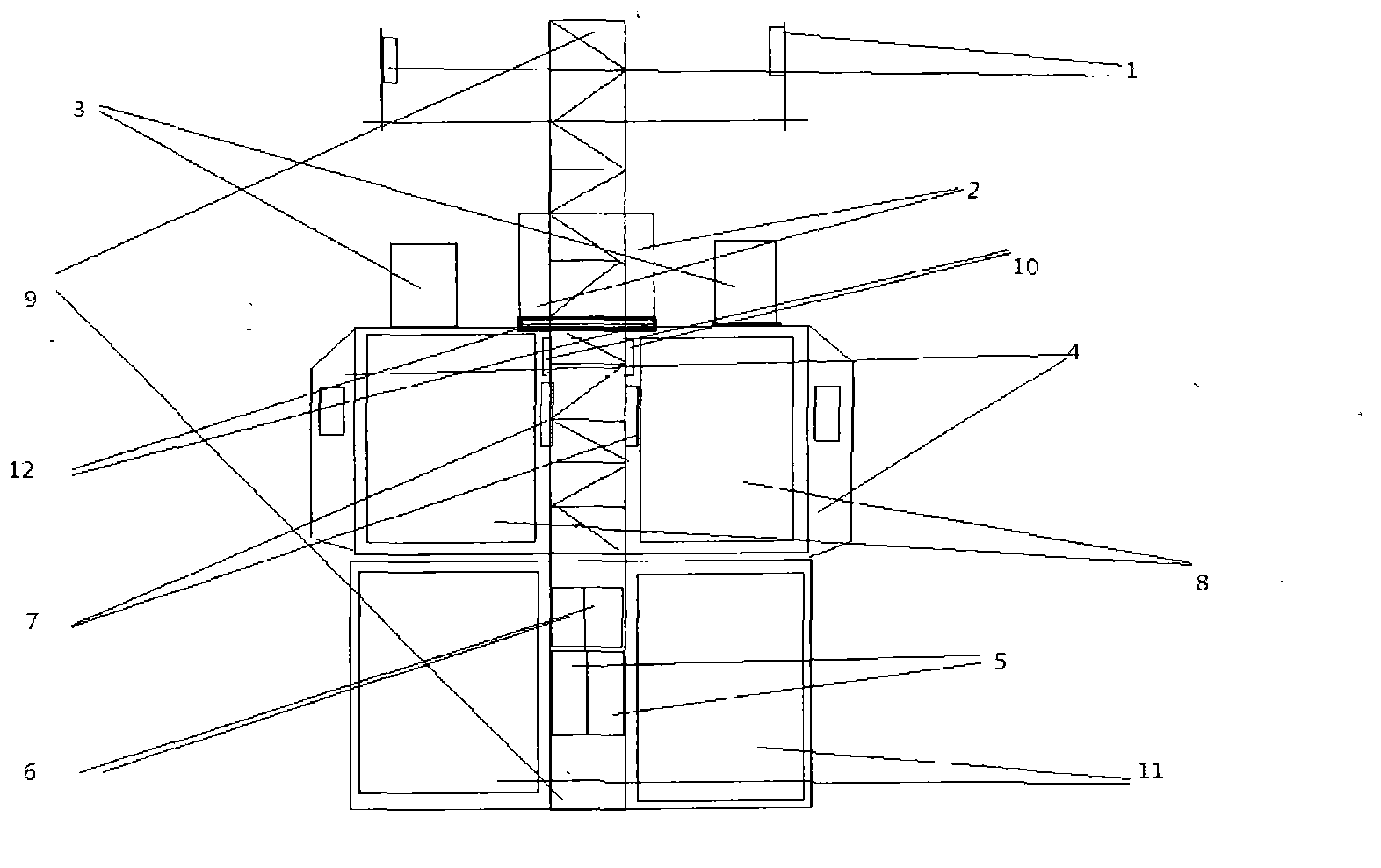

[0012] see figure 1 , Schematic diagram of the structure of the automatic control system for construction elevators without special operation, automatic control of construction elevators without special operation, including: 1: floor call elevator 1+N, 2: drive mechanism, 3: electric control box, 4: operating room, 5: Ground call elevator, 6: main distribution box, 7: cage call elevator, 8: car cage, 9: main engine, 10: anti-fall safety device, 11: fence 12: weight protection controller.

[0013] The computer control system of the electric control box can realize unattended operation, automatic leveling, and excellent precision and balance.

[0014] This machine adopts integrated control, and the VVVF variable frequency drive system ensures the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com