Fluorine-containing polymer functionalized carbon nanotube and preparation method thereof

A technology of carbon nanotubes and single-walled carbon nanotubes, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as the danger of big explosions and the inapplicability of acute toxicity , to achieve the effects of low preparation cost, overcoming danger and severe toxicity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

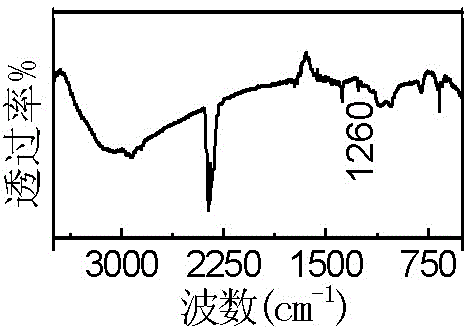

Image

Examples

Embodiment 1

[0035] A carbon nanotube functionalized with a fluorine-containing high polymer is prepared by a method comprising the following steps:

[0036] (1) Calculated according to the mass ratio, that is, the ratio of carbon nanotubes: fluorine-containing monomer is 1:5, put 0.3g of carbon nanotubes and 1.5g of fluorine-containing monomer into the vacuum chamber of the plasma chemical vapor deposition furnace , when evacuated to 0.1Pa, high-purity argon gas is introduced at a temperature of 10°C, the pressure of the vacuum chamber is adjusted to 10Pa, and the plasma power of 50W is used for 10min;

[0037] The carbon nanotubes are multi-walled carbon nanotubes with a diameter of 10-20nm, a length of 5-15mm, and a purity>97%;

[0038] The fluorine-containing monomer is a perfluoroalkyl methacrylate with a molecular weight of 142;

[0039] (2) Introduce high-purity oxygen into the vacuum chamber for 5 minutes, then heat it to 80°C, and process it with a plasma power of 30W for 20 minu...

Embodiment 2

[0044] A carbon nanotube functionalized with a fluorine-containing high polymer is prepared by a method comprising the following steps:

[0045] (1) Calculated according to the mass ratio, that is, the ratio of carbon nanotubes: fluorine-containing monomer is 1:5, put 0.3g of carbon nanotubes and 1.5g of fluorine-containing monomer into the vacuum chamber of the plasma chemical vapor deposition furnace , when evacuated to 0.1Pa, high-purity argon gas is introduced at a temperature of 15°C, the pressure of the vacuum chamber is adjusted to 10Pa, and the plasma power of 65W is used for the first plasma treatment for 20min;

[0046] The carbon nanotubes are double-walled carbon nanotubes with diameter90%;

[0047] The fluorine-containing monomer is perfluoroamidomethacrylate with a molecular weight of 312;

[0048] (2) Introduce high-purity oxygen into the vacuum chamber for 5 minutes, then heat to 80° C., and perform a second plasma treatment for 20 minutes with a plasma power ...

Embodiment 3

[0052] A carbon nanotube functionalized with a fluorine-containing high polymer is prepared by a method comprising the following steps:

[0053] (1) Calculated according to the mass ratio, that is, the ratio of carbon nanotubes: fluorine-containing monomer is 1:2, put 0.3g of carbon nanotubes and 0.6g of fluorine-containing monomer into the vacuum chamber of the plasma chemical vapor deposition furnace , when evacuated to 0.1Pa, high-purity argon gas is introduced at a temperature of 25°C, the pressure of the vacuum chamber is adjusted to 10Pa, and the plasma power of 50W is used for the first plasma treatment for 10min;

[0054] The carbon nanotubes are single-walled carbon nanotubes with diameter90%;

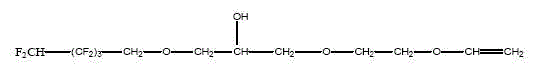

[0055] The fluorine-containing monomer is a fluorine-containing enol with a hydroxyl group, and its structural formula is as follows:

[0056]

[0057] (2) Introduce high-purity oxygen into the vacuum chamber for 10 minutes, then heat to 50° C., and perform a second plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com