Fluorine-containing polymer functionalized carbon nanotube and preparation method thereof

A carbon nanotube, single-walled carbon nanotube technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as acute toxicity, unsuitability for large explosions, etc. , to achieve the effect of overcoming danger and acute toxicity, low preparation cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A carbon nanotube functionalized with a fluorine-containing high polymer is prepared by a method comprising the following steps:

[0036] (1) Calculated according to the mass ratio, that is, the ratio of carbon nanotubes: fluorine-containing monomer is 1:5, put 0.3g of carbon nanotubes and 1.5g of fluorine-containing monomer into the vacuum chamber of the plasma chemical vapor deposition furnace , when evacuated to 0.1Pa, high-purity argon gas is introduced at a temperature of 10°C, the pressure of the vacuum chamber is adjusted to 10Pa, and the plasma power of 50W is used for 10min;

[0037] The carbon nanotubes are multi-walled carbon nanotubes with a diameter of 10-20nm, a length of 5-15mm, and a purity>97%;

[0038] The fluorine-containing monomer is a perfluoroalkyl methacrylate with a molecular weight of 142;

[0039] (2) Introduce high-purity oxygen into the vacuum chamber for 5 minutes, then heat it to 80°C, and process it with a plasma power of 30W for 20 minu...

Embodiment 2

[0044] A carbon nanotube functionalized with a fluorine-containing high polymer is prepared by a method comprising the following steps:

[0045] (1) Calculated according to the mass ratio, that is, the ratio of carbon nanotubes: fluorine-containing monomer is 1:5, put 0.3g of carbon nanotubes and 1.5g of fluorine-containing monomer into the vacuum chamber of the plasma chemical vapor deposition furnace , when evacuated to 0.1Pa, high-purity argon gas is introduced at a temperature of 15°C, the pressure of the vacuum chamber is adjusted to 10Pa, and the plasma power of 65W is used for the first plasma treatment for 20min;

[0046] The carbon nanotubes are double-walled carbon nanotubes with diameter90%;

[0047] The fluorine-containing monomer is perfluoroamidomethacrylate with a molecular weight of 312;

[0048] (2) Introduce high-purity oxygen into the vacuum chamber for 5 minutes, then heat to 80° C., and perform a second plasma treatment for 20 minutes with a plasma power ...

Embodiment 3

[0052] A carbon nanotube functionalized with a fluorine-containing high polymer is prepared by a method comprising the following steps:

[0053] (1) Calculated according to the mass ratio, that is, the ratio of carbon nanotubes: fluorine-containing monomer is 1:2, put 0.3g of carbon nanotubes and 0.6g of fluorine-containing monomer into the vacuum chamber of the plasma chemical vapor deposition furnace , when evacuated to 0.1Pa, high-purity argon gas is introduced at a temperature of 25°C, the pressure of the vacuum chamber is adjusted to 10Pa, and the plasma power of 50W is used for the first plasma treatment for 10min;

[0054] The carbon nanotubes are single-walled carbon nanotubes with diameter90%;

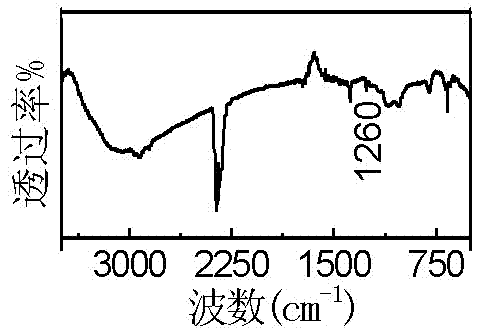

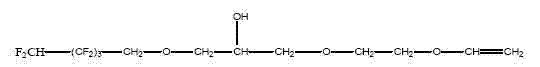

[0055] The fluorine-containing monomer is a fluorine-containing enol with a hydroxyl group, and its structural formula is as follows:

[0056]

[0057] (2) Introduce high-purity oxygen into the vacuum chamber for 10 minutes, then heat to 50° C., and perform a second plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com