Method for effectively controlling sludge bulking caused by chlorine resistant filamentous bacteria

A technology of sludge bulking and filamentous bacteria, which is applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effect of restoring sludge settling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

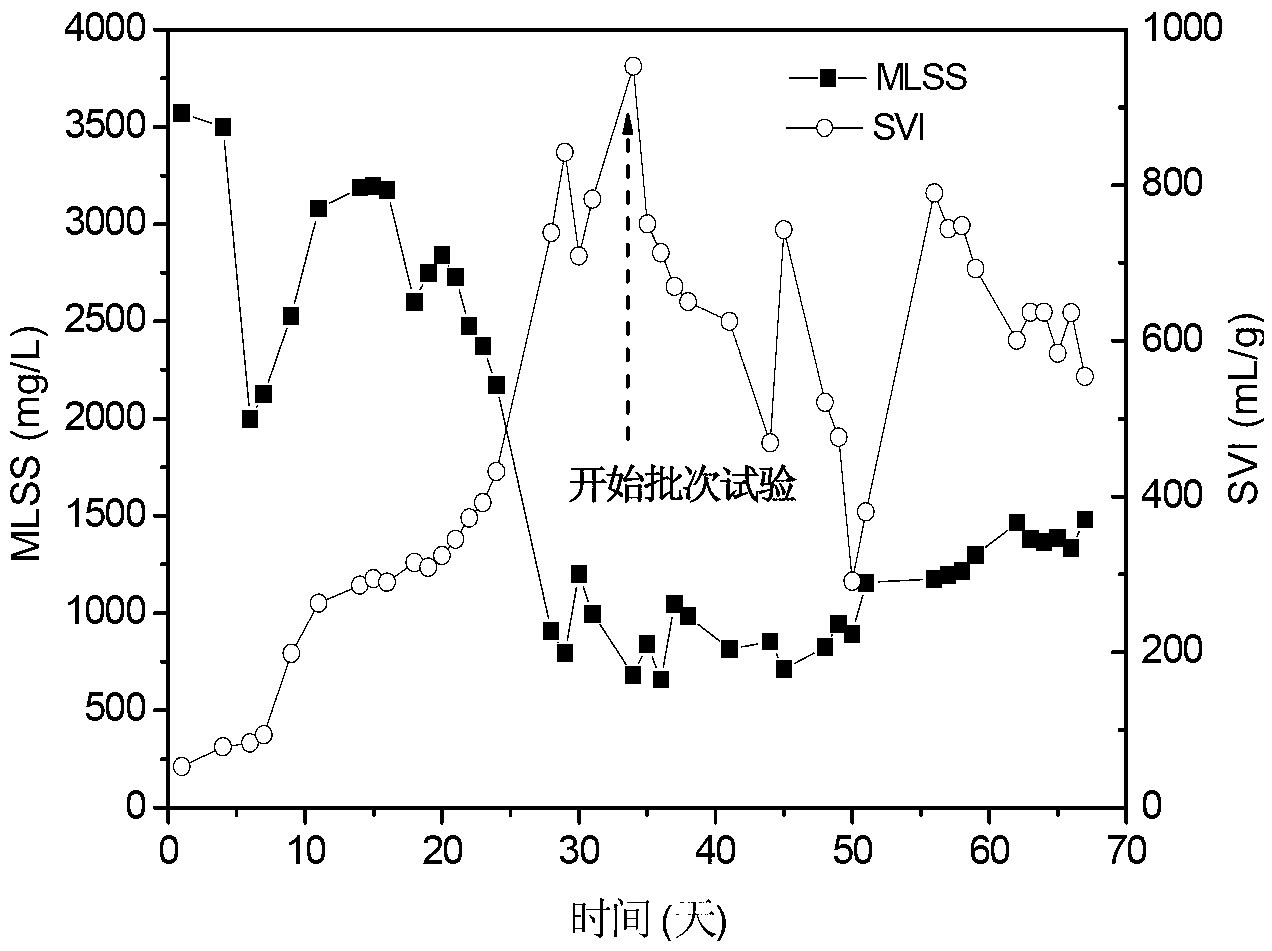

[0017] Example 1: Malignant sludge bulking A / O reactor induced by low substrate concentration combined with low DO. At that time, the SVI of the sludge in the reactor was as high as 700mL / g, and there was obvious sludge loss in the secondary settling tank, and the MLSS concentration in the reactor showed an obvious downward trend. figure 1 The expansion state of the sludge in the A / O reactor and the time node of taking the sludge for the batch test of adding chemicals are given. Staining and FISH identification of filamentous bacteria showed that the dominant filamentous bacteria were mainly Type021N and S.natans, and the filamentous bacteria index was 4-5.

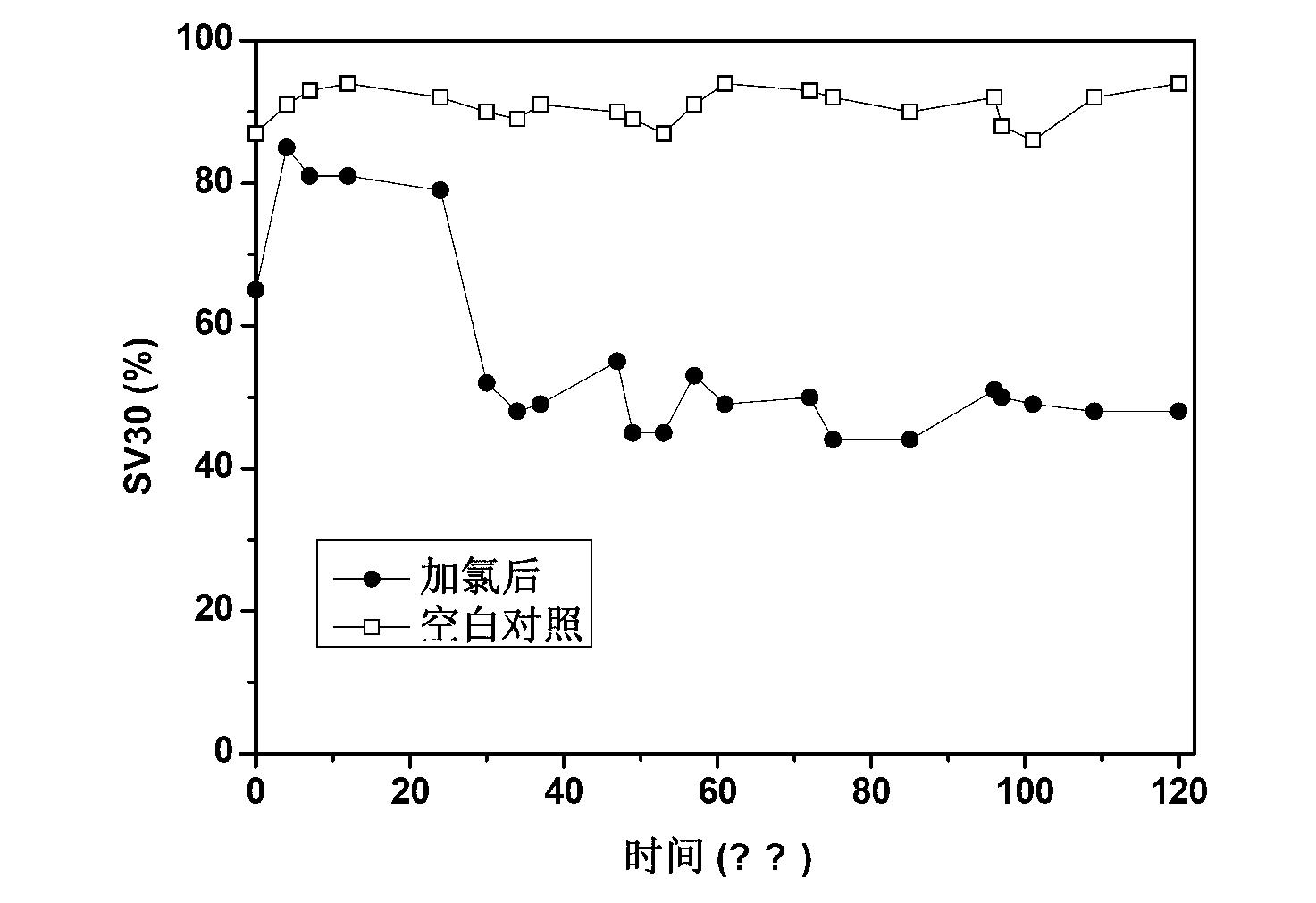

[0018] A part of the sludge was taken out from the bottom of the secondary sedimentation tank of the A / O reactor, and the supernatant was discarded after the sludge was centrifuged at 2000rmp for 2min. Finally, the sludge was divided into several parts according to the same amount, and put into 1.5L test device respectiv...

Embodiment 2

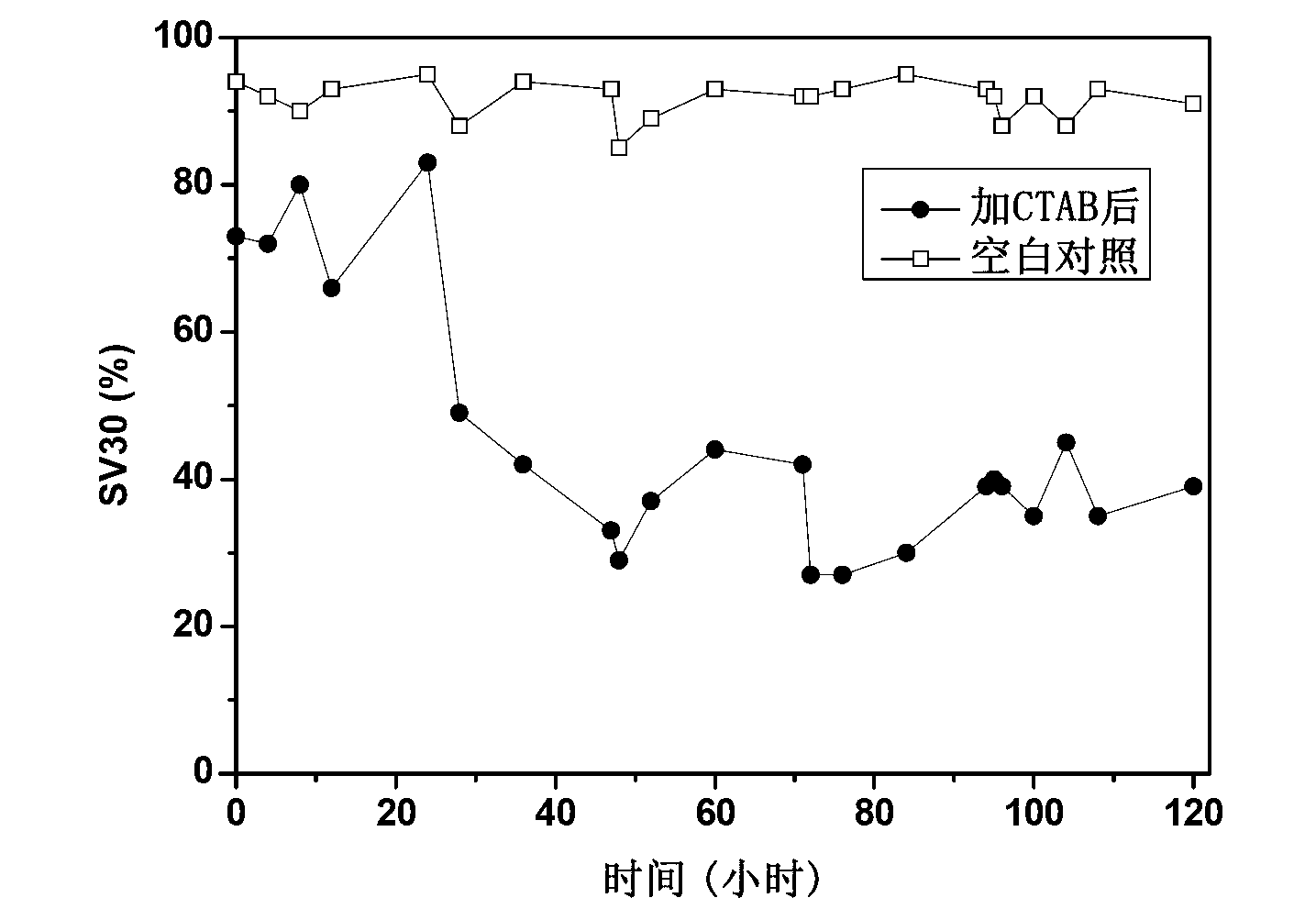

[0029] Low substrate concentration combined with low DO-initiated malignant sludge bulking A / O reactor. At that time, the SVI of the sludge in the reactor was as high as 700mL / g, and there was obvious sludge loss in the secondary settling tank, and the MLSS concentration in the reactor showed an obvious downward trend. Staining and FISH identification of filamentous bacteria showed that the dominant filamentous bacteria were mainly Type021N, and the filamentous bacteria index was 5. After passing the batch test adopted in Example 1, the results showed that the type 021N filamentous bacteria contained in the bulking sludge is a chlorine-resistant filamentous bacteria. Therefore, half a month after the sludge bulking in the A / O reactor, the CTAB agent was added in the influent anoxic zone of the A / O reaction at the dosage of 30mgCTAB / gMLSS, and only 1 Once, within 5 days, it was found that the SVI in the A / O reactor decreased to 200mL / g, and the filamentous bacteria index decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com