Polyamide (PA)/acrylonitrile butadiene styrene (ABS) composite material

A composite material and modification technology, which is applied in the field of plastic alloys, can solve problems such as poor compatibility, and achieve the effect of improved compatibility, resistance to strong acid and strong alkali corrosion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

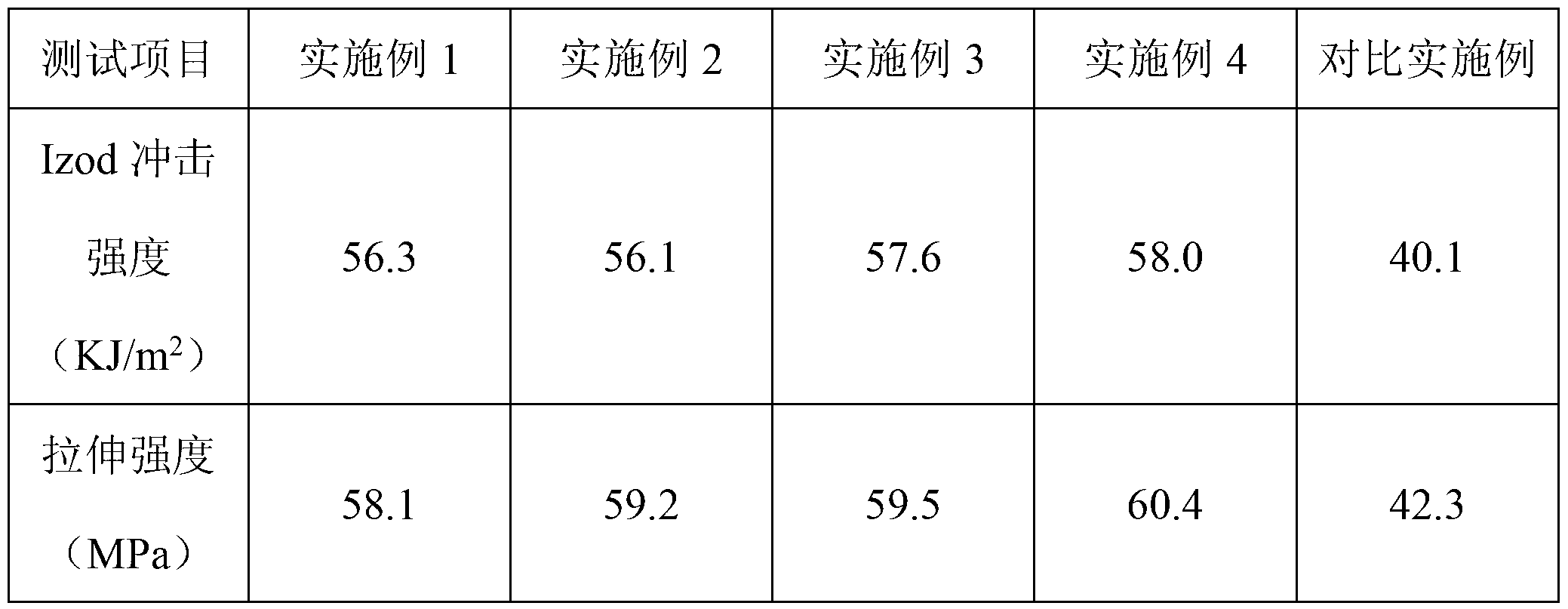

Examples

Embodiment 1

[0017] 55 parts of PA, 40 parts of ABS, 5 parts of modified PS, 1 part of initiator dimethylaminoethyl methacrylate, antioxidant tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid ) 0.1 part of pentaerythritol ester is pre-mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

Embodiment 2

[0019] 58 parts of PA, 43 parts of ABS, 6 parts of modified PS, 2 parts of initiator dimethylaminoethyl methacrylate, antioxidant β-(4-hydroxyphenyl-3,5-di-tert-butyl) propionic acid 0.2 parts of octa-carbon alcohol esters were pre-mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

Embodiment 3

[0021] 62 parts of PA, 46 parts of ABS, 7 parts of modified PS, 1 part of initiator N-dimethylaniline, and 0.3 parts of antioxidant 2,6-di-tert-butyl-p-cresol are pre-mixed in a high-speed mixer, and then passed Extruded by parallel twin-screw mixing extruder, cooled and granulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com