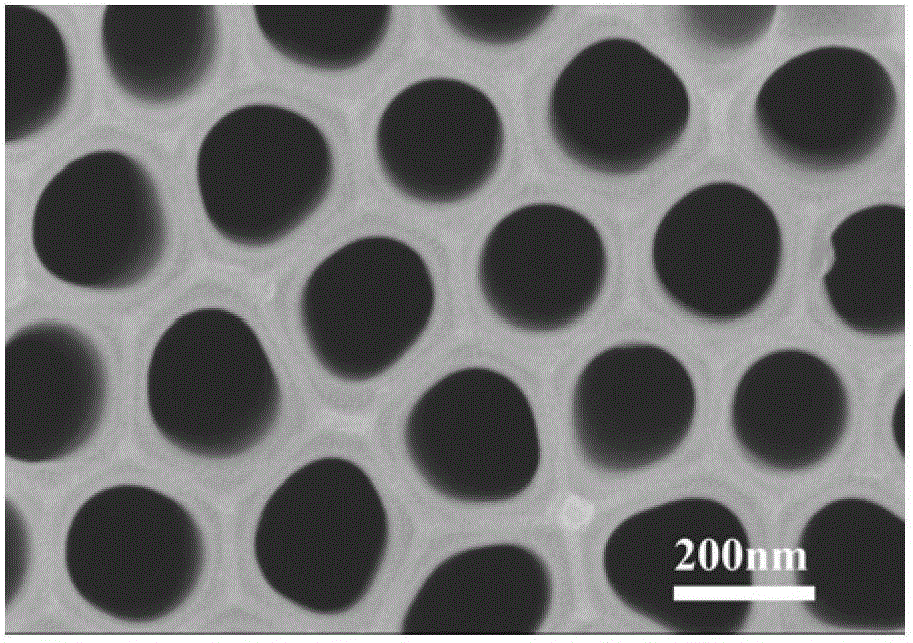

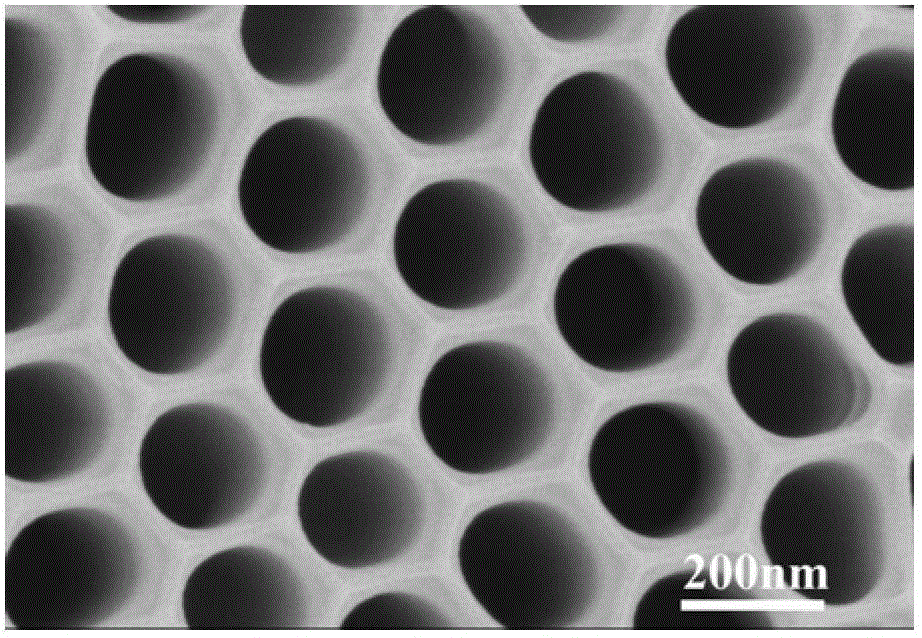

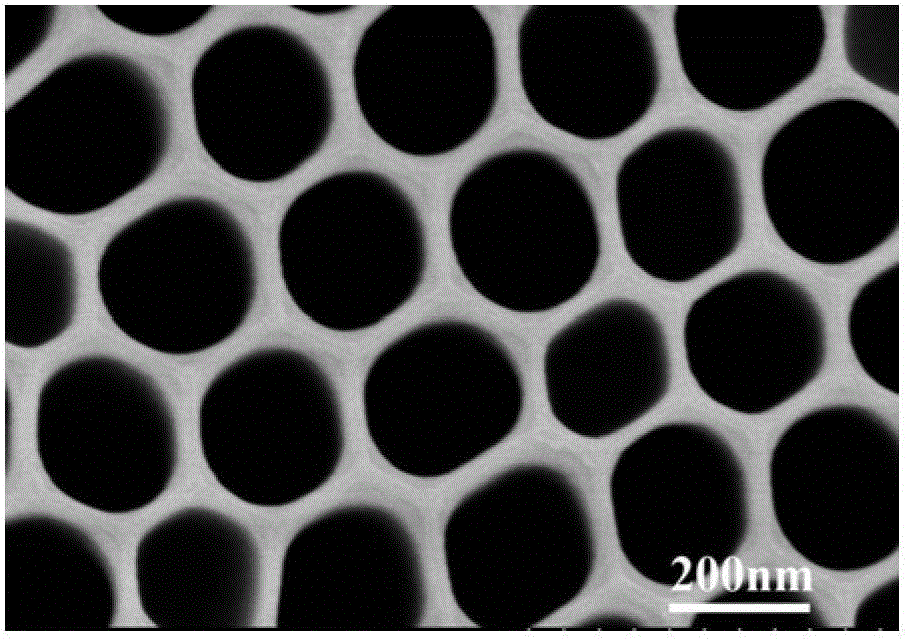

A method for preparing ordered macroporous anodic aluminum oxide films by two-step anodic oxidation

An anodic oxidation method and anodic oxidation technology are applied in the field of preparing ordered macroporous anodic aluminum oxide films by two-step anodic oxidation method, which can solve problems such as poor order, complicated cost, and difficult to achieve experimental conditions, so as to avoid Ablation phenomenon, low cost, effect of improving order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) High-purity aluminum flakes (purity 99.999wt%) are annealed at 400°C for 4 hours under the protection of an inert gas (such as nitrogen) to eliminate the mechanical stress on the surface and inside of the aluminum flakes, and at the same time help to improve the aluminum grains. size;

[0043] (2) Use a degreasing solution composed of ethanol, methylene chloride and acetone (the volume ratio of ethanol, methylene chloride and acetone is 1:2:1) to ultrasonically clean for 10 minutes to remove the grease and oil on the surface of the aluminum sheet after the treatment in step (1). dirt;

[0044] (3) Clean the ultrasonically treated aluminum sheet with deionized water, and use a polishing solution composed of deionized water, 98wt% sulfuric acid, 85wt% phosphoric acid and ethylene glycol at 91 °C (deionized water, 98wt% sulfuric acid, 85wt% phosphoric acid and ethylene glycol) The volume ratio of diol is 4:1:3:2) at a current density of 22A / dm 2 Constant current elec...

Embodiment 2

[0050] (1) High-purity aluminum flakes (purity 99.999wt%) are annealed at 400°C for 3 hours under the protection of an inert gas (such as nitrogen) to eliminate the mechanical stress on the surface and inside of the aluminum flakes, and at the same time help to improve the aluminum grains. size;

[0051] (2) Use a degreasing solution composed of ethanol, methylene chloride and acetone (the volume ratio of ethanol, methylene chloride and acetone is 1:2:1) to ultrasonically clean for 15 minutes to remove the grease and oil on the surface of the aluminum sheet after the treatment in step (1). dirt;

[0052] (3) Clean the ultrasonically treated aluminum sheet with deionized water, and use a polishing solution composed of deionized water, 98wt% sulfuric acid, 85wt% phosphoric acid and ethylene glycol at 90°C (deionized water, 98wt% sulfuric acid, 85wt% phosphoric acid and ethylene glycol) The volume ratio of diol is 4:1:3:2) at a current density of 23A / dm 2 Constant current elect...

Embodiment 3

[0058] (1) High-purity aluminum flakes (purity 99.999wt%) are annealed at 400°C for 4 hours under the protection of an inert gas (such as nitrogen) to eliminate the mechanical stress on the surface and inside of the aluminum flakes, and at the same time help to improve the aluminum grains. size;

[0059] (2) Use a degreasing solution composed of ethanol, methylene chloride and acetone (the volume ratio of ethanol, methylene chloride and acetone is 1:2:1) to ultrasonically clean for 15 minutes to remove the grease and oil on the surface of the aluminum sheet after the treatment in step (1). dirt;

[0060] (3) Clean the ultrasonically treated aluminum sheet with deionized water, and use a polishing solution composed of deionized water, 98wt% sulfuric acid, 85wt% phosphoric acid and ethylene glycol at 91 °C (deionized water, 98wt% sulfuric acid, 85wt% phosphoric acid and ethylene glycol) The volume ratio of diol is 4:1:3:2) at a current density of 23A / dm 2 Constant current elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com