Camellia oleifera seed shell activated carbon and its preparation process

Camellia oleifera seed husk and preparation technology, which can be used in other chemical processes, catalyst carriers, physical/chemical process catalysts, etc., can solve problems such as waste, loss of active substances in oleifera seed husk, and achieve improved dissolution rate, increased added value, The effect of significant immune activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

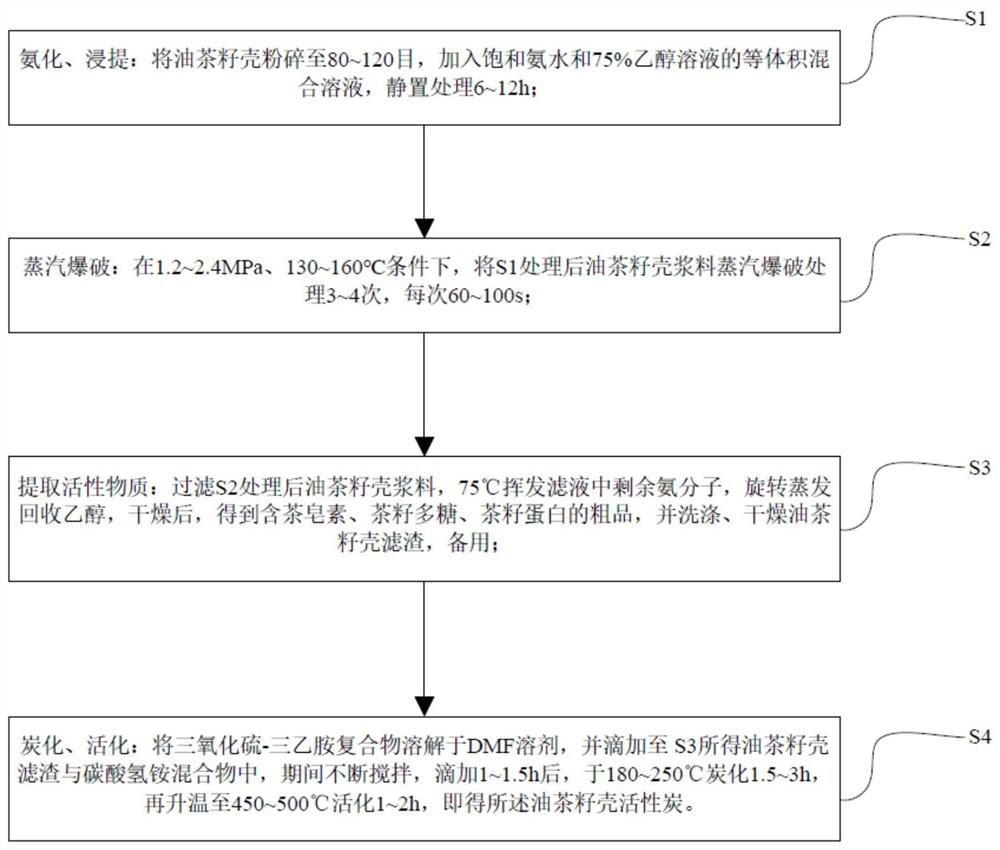

Method used

Image

Examples

Embodiment 1

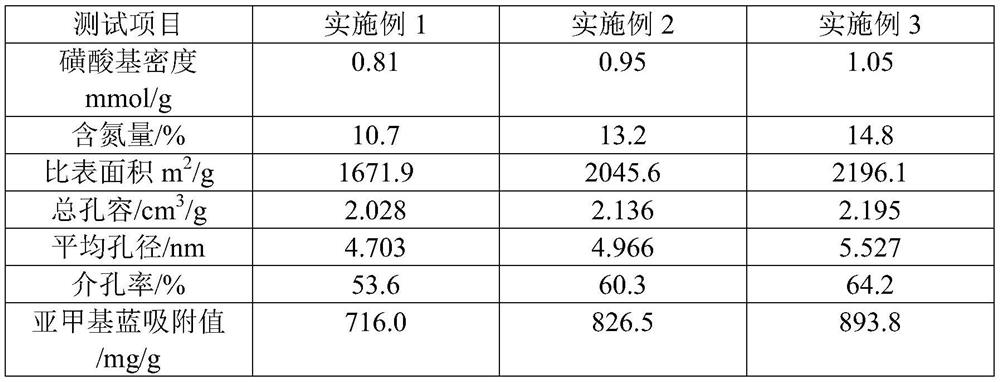

[0020] Example 1 Preparation of Nitrogen-doped Sulfonated Mesoporous Activated Carbon Using Camellia oleifera Seed Shell

[0021] S1: Ammonification and extraction: crush 20g of camellia oleifera seed shells to 100 mesh, add 16ml of saturated ammonia + 16ml of 75% ethanol solution, and let it stand for 6 hours;

[0022] S2: Steam explosion: Under the conditions of 1.2MPa and 130°C, steam the camellia seed shell slurry treated in S1 for 3 times, 60s each time;

[0023] S3: Extract active substances: filter the camellia seed shell slurry treated in S2, volatilize the remaining ammonia molecules in the filtrate at 75°C, recover ethanol by rotary evaporation, and obtain the crude product containing tea saponin, tea seed polysaccharide, and tea seed protein after drying, and Wash and dry the filter residue of camellia oleifera seed shell, and set aside;

[0024] S4: Carbonization and activation: Dissolve 1.5g of sulfur trioxide-triethylamine complex in 3ml of DMF solvent, and add ...

Embodiment 2

[0025] Example 2 Preparation of Nitrogen-Doped Sulfonated Mesoporous Activated Carbon Using Camellia oleifera Seed Shells

[0026] S1: Ammonification and extraction: crush 20g of camellia oleifera seed shells to 100 mesh, add 20ml of saturated ammonia water + 20ml of 75% ethanol solution, and let it stand for 6-12 hours;

[0027] S2: Steam explosion: Under the conditions of 1.8MPa and 140°C, steam the camellia seed shell slurry treated in S1 for 4 times, 90s each time;

[0028] S3: Extract active substances: filter the camellia seed shell slurry treated in S2, volatilize the remaining ammonia molecules in the filtrate at 75°C, recover ethanol by rotary evaporation, and obtain the crude product containing tea saponin, tea seed polysaccharide, and tea seed protein after drying, and Wash and dry the filter residue of camellia oleifera seed shell, and set aside;

[0029] S4: Carbonization and activation: Dissolve 1.8g of sulfur trioxide-triethylamine complex in 4ml of DMF solvent...

Embodiment 3

[0030] Example 3 Preparation of Nitrogen-Doped Sulfonated Mesoporous Activated Carbon Using Camellia oleifera Seed Shells

[0031] S1: Ammonification and extraction: crush 20g of camellia oleifera seed shells to 100 mesh, add 20ml of saturated ammonia water + 20ml of 75% ethanol solution, and let it stand for 12 hours;

[0032] S2: Steam explosion: Under the conditions of 2.4MPa and 150°C, steam the camellia seed shell slurry treated in S1 for 4 times, 100s each time;

[0033] S3: Extract active substances: filter the camellia seed shell slurry treated in S2, volatilize the remaining ammonia molecules in the filtrate at 75°C, recover ethanol by rotary evaporation, and obtain the crude product containing tea saponin, tea seed polysaccharide, and tea seed protein after drying, and Wash and dry the filter residue of camellia oleifera seed shell, and set aside;

[0034] S4: Carbonization and activation: Dissolve 2.0g of sulfur trioxide-triethylamine complex in 5ml of DMF solvent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com