A diffuser end wall of a steam turbine exhaust system on one side

A diffuser and steam turbine technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problem of not considering the aerodynamic interaction between the turbine and the exhaust system, so as to reduce the degree of circumferential unevenness and increase the permeability. The effect of leveling work and reducing back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

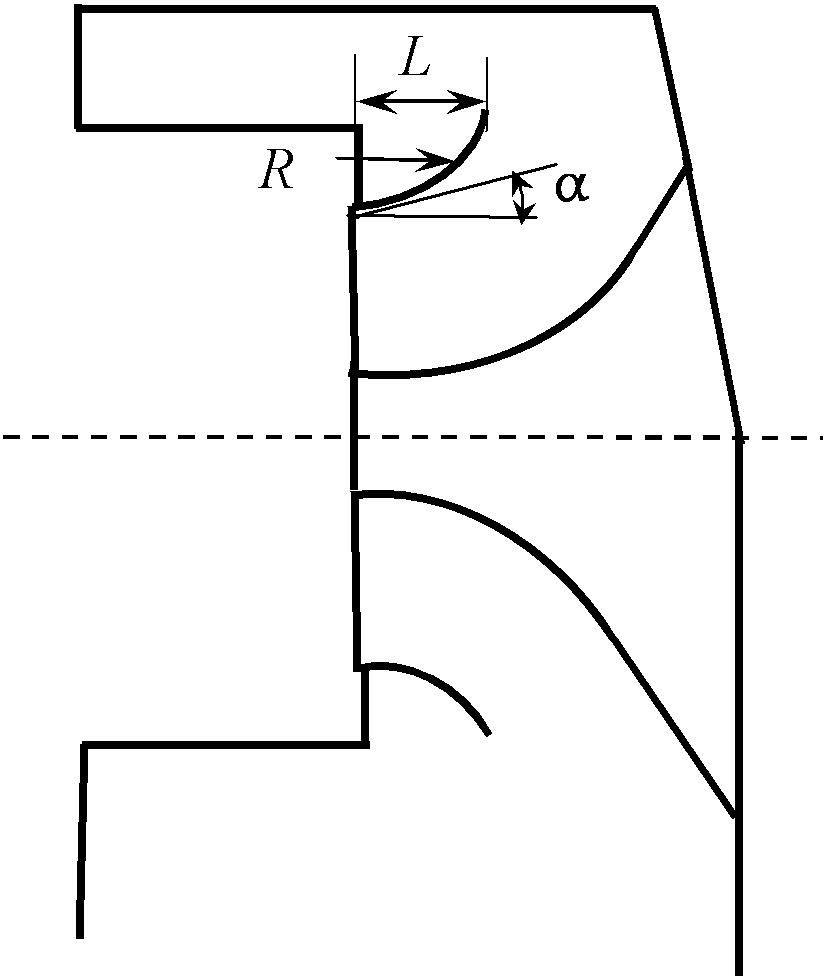

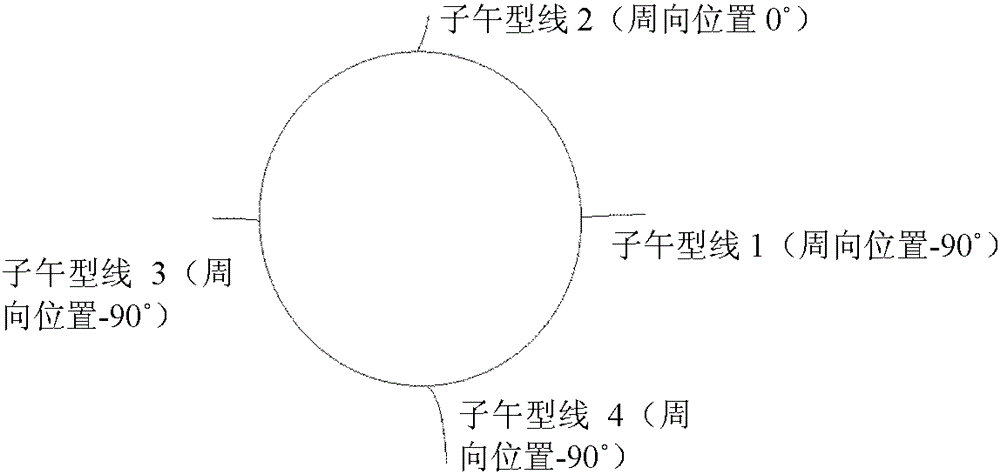

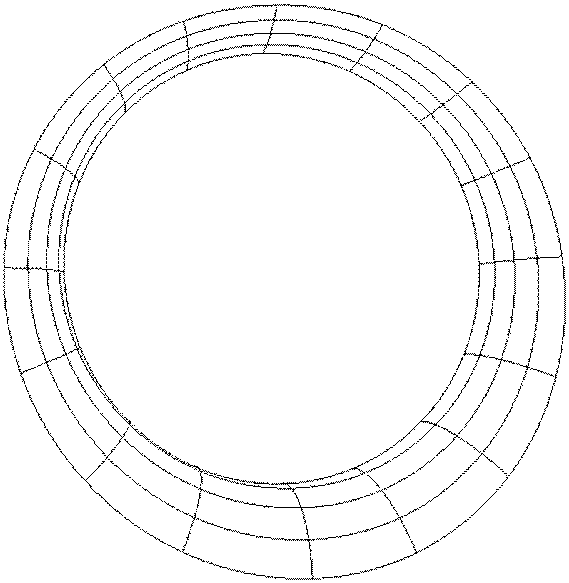

[0022] The diffuser end wall of a steam turbine unilateral exhaust system of the present invention is based on the strong aerodynamic interaction between the turbine blade row and the unilateral radial exhaust system, and proposes a new design idea and structural form . This design method proposes a full three-dimensional design of the end wall of the diffuser in the steam turbine exhaust system. In the design, according to the actual turbine outlet flow field, different meridian lines are used at different circumferential positions (see Figure 2a ), smoothly interpolate the profile lines along the circumferential direction to form the end wall profile of the diffuser (see Figure 2b ). This design method, in the actual operating environment, can not only ensure that the exhaust system has a good diffusion capacity, but also reduce the back pressure of the turbine outlet (see Table 1 and Figure 4 ), increase the turbine output and improve the thermal efficiency of the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com