Mass flow high-frequency direct-acting electro-hydraulic servo valve based on great magnetostriction converter

A giant magnetostrictive and electro-hydraulic servo valve technology, which is applied to servo motor components, fluid pressure actuators, mechanical equipment, etc., to achieve the effects of high system reliability, fast response speed, and large displacement magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

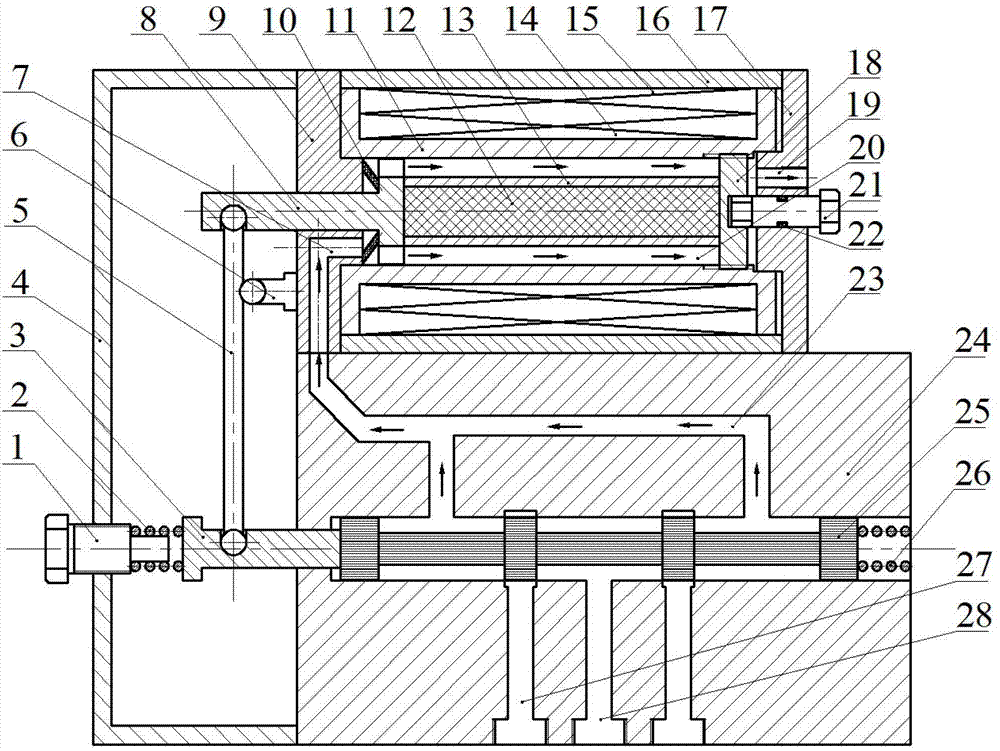

[0032] as attached figure 1 As shown, the high-flow high-frequency direct-acting electro-hydraulic servo valve based on the giant magnetostrictive converter is mainly composed of the valve body, the giant magnetostrictive converter located above the valve body, and the left side of the valve body and the giant magnetostrictive converter. It is composed of the micro-displacement amplifying mechanism on the side and the shell, and the spool valve reset and zero-adjustment device located inside the valve body and on the left side.

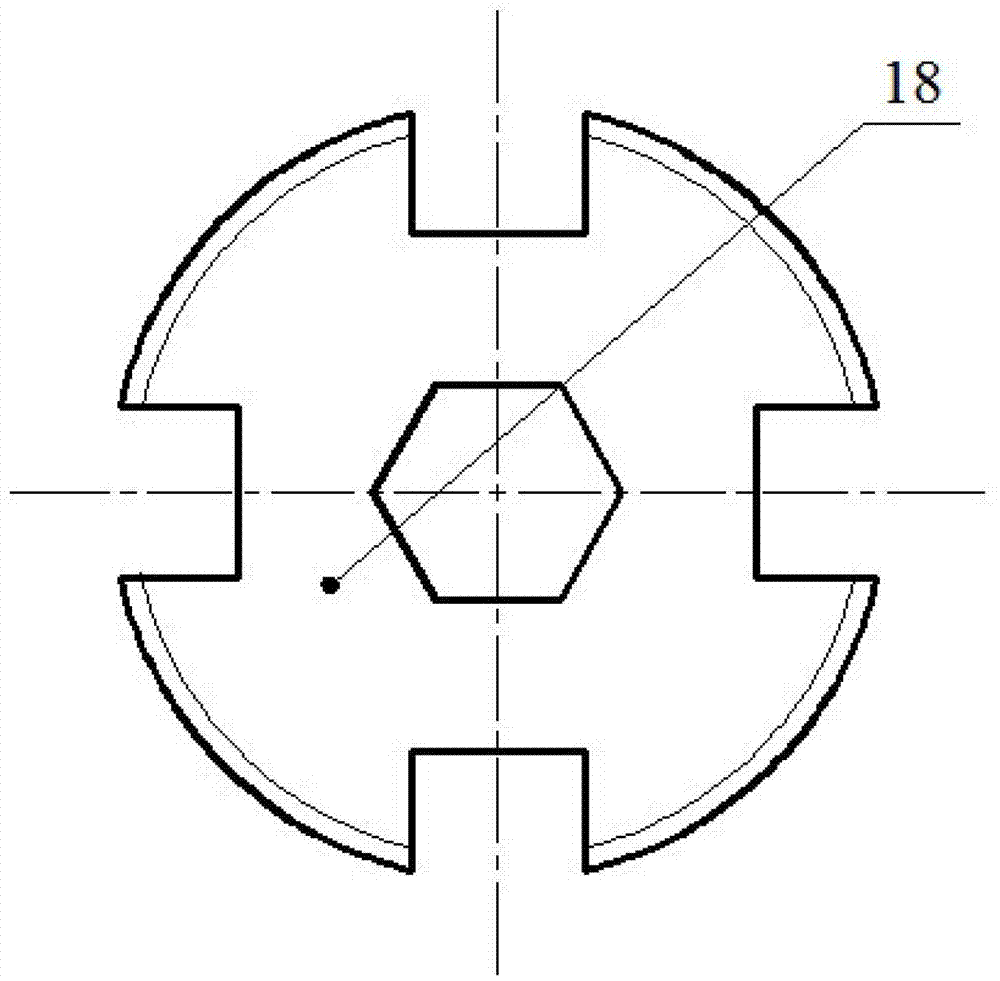

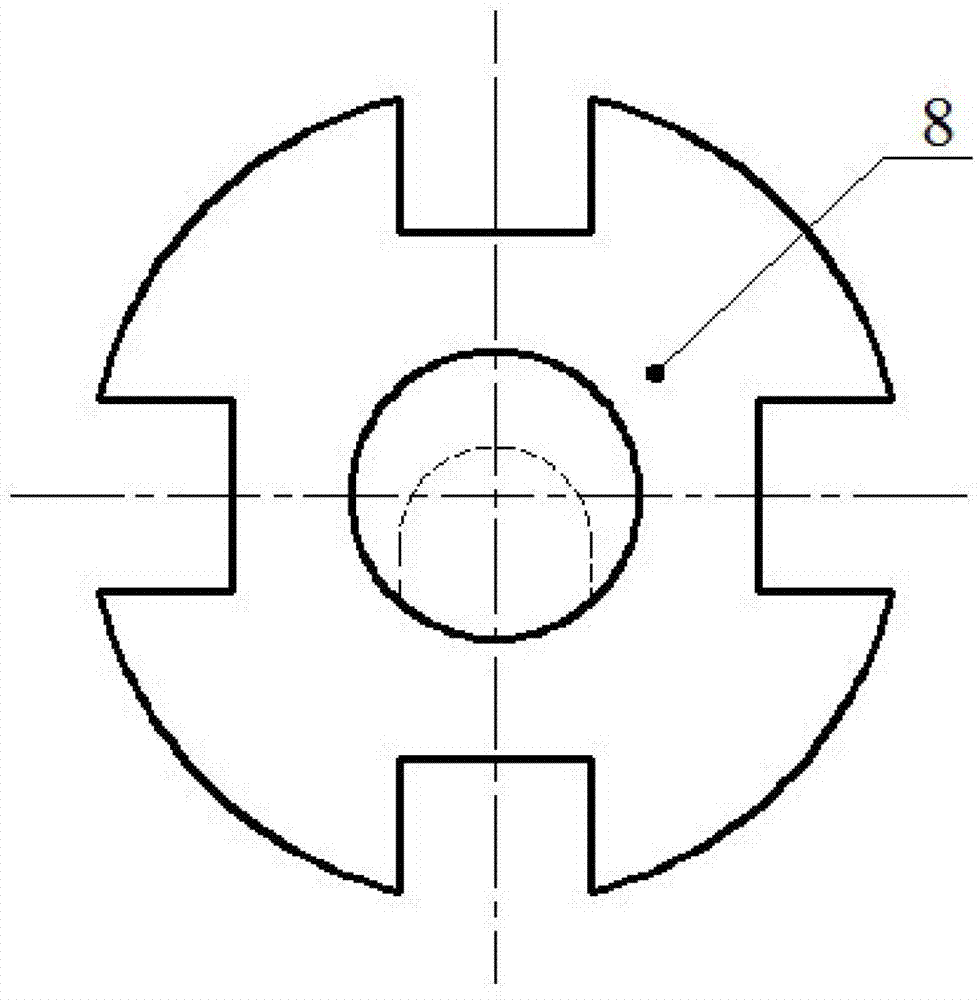

[0033] The function of the giant magnetostrictive converter is to convert the input current signal into an output displacement, which includes a left end cover, a right end cover, a preload spring installed along the axial position of the left end cover and the right end cover, a converter displacement output rod, Giant magnetostrictive rod, pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com