Method of controlling position engagement for wet dual-clutch transmission

A wet dual-clutch, transmission technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of poor target followability, errors, instability, etc., and achieve simplified gears The effect of engaging actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The features and advantages of the present invention have been described in the above text, and the present invention can be better understood after reading the following description and the accompanying drawings.

[0038] The present invention is described in detail below according to accompanying drawing:

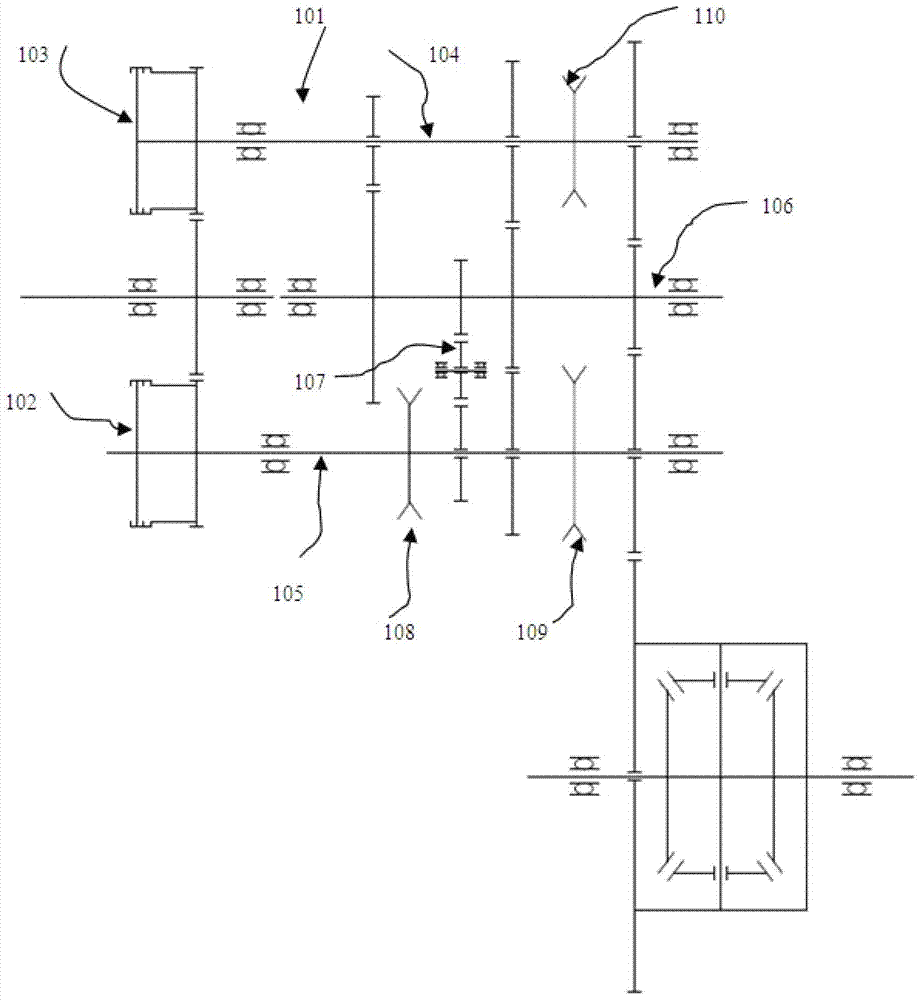

[0039] The DCT is controlled by the control method shown, see figure 1 In the schematic diagram above, the dual-clutch gearbox 101 includes two sets of clutch assemblies, which are shown on 102 and 103 . What 104 shows is the odd-numbered input shaft, and what 105 shows is the even-numbered input shaft. The odd and even two shafts are parallel, 106 is an intermediate shaft, 107 is a reverse gear intermediate shaft, and a plurality of synchronizers are shown in 108, 109 and 110.

[0040] The dual-clutch gearbox 101 transmits the torque from the engine, through selectable gear ratios to the drive shaft, and finally to the wheels. The transmission route of the dual-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com